FOCKE MELER GLUING SOLUTIONS

4-32

MELTER OPERATION

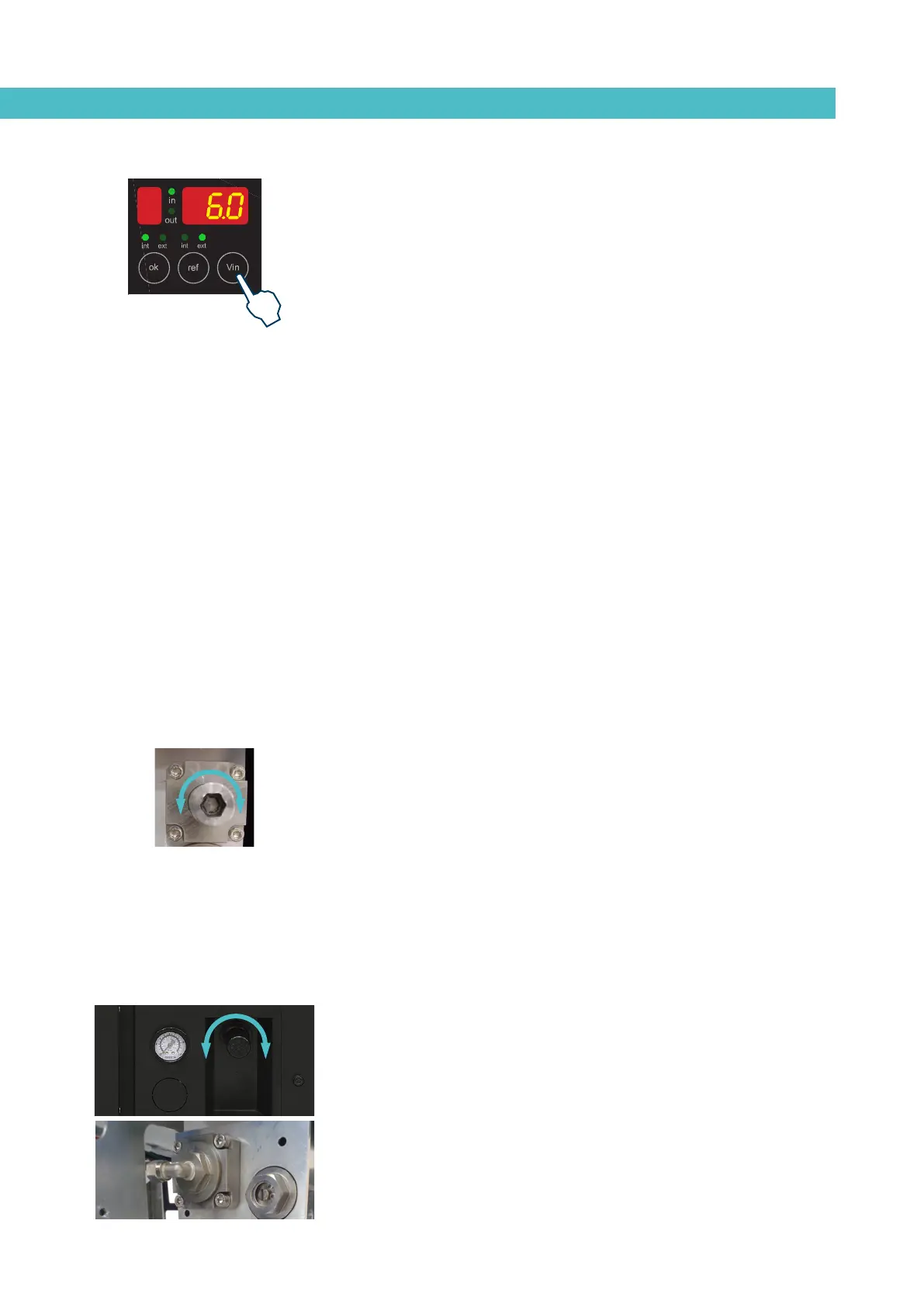

Current Vin voltage display

Whenever the Vin key is held pressed, the three digits on the right will show

the input voltage reading to one decimal point.

If the values for any point in the speed ramp table is being edited, and the Vin

key is held pressed for 3 seconds, the voltage value which is operating at this

time it will be copied to that value on the table.

By-pass valve regulation

The pumping system using a geared pump provides a constant flow of

adhesive, according to the pump’s rotational speed.

In this type of system, the pressure generated by the pump is the result of the

retentions found on the circuit (the length and diameter of the hose, elbows

in the connectors, the diameters of the nozzle outputs, etc.) and the adhesive

itself (its viscosity).

For safety reasons, this pressure must be discharged when the circuit exceeds

the operating value (normally with a closed circuit and the pump activated),

which makes the use of a discharge valve or a by-pass valve necessary.

This valve may be a manual adjustment valve, using a threaded screw, or

with pneumatic control, using a pressure regulator and a pressure gauge. In

the latter case, the adhesive circuit pressure has a 1:13 ratio to the pressure

displayed on the pressure gauge.

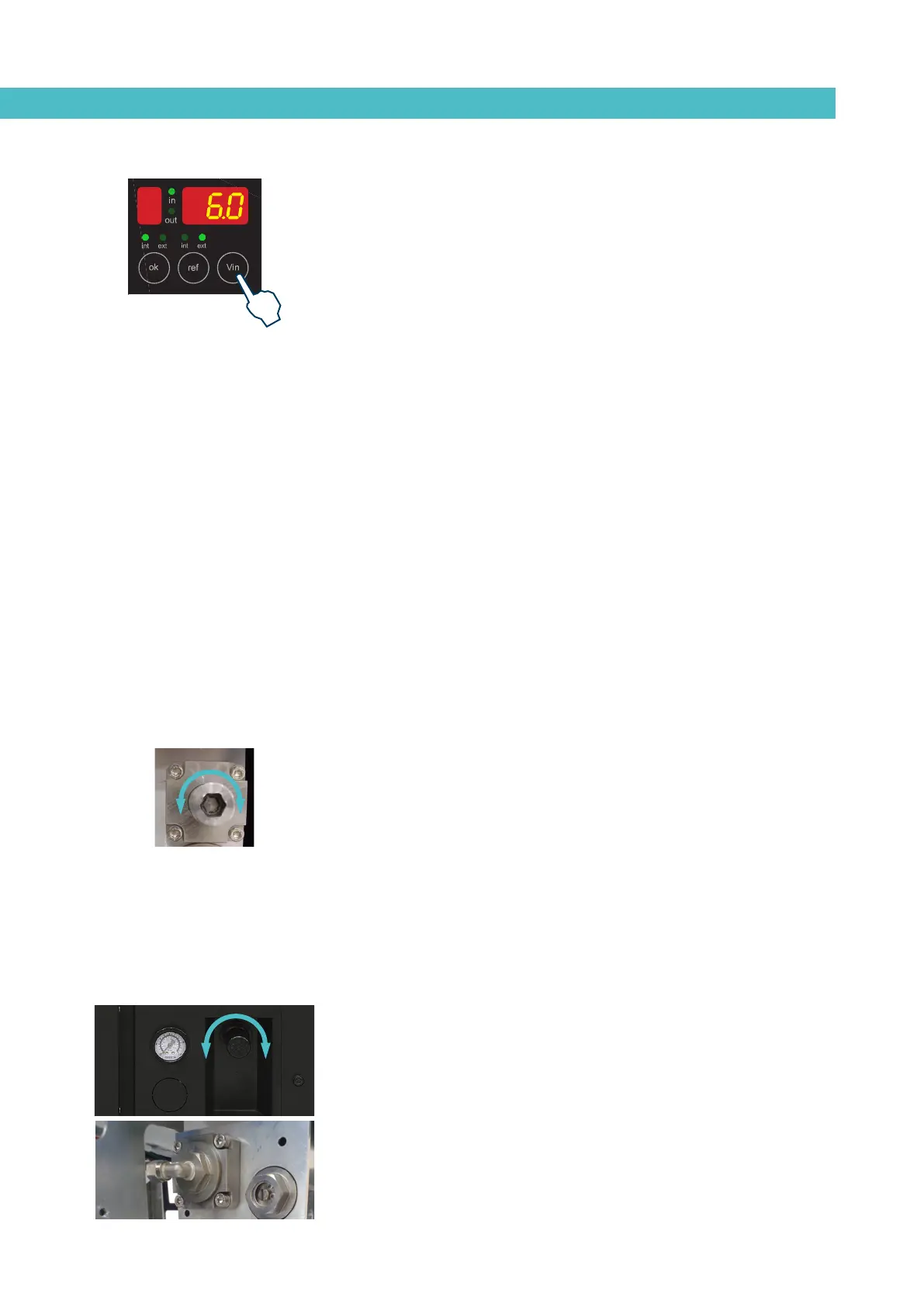

Manual valve control

To adjust the pressure with this valve model (in an approximate manner),

follow these steps:

1. Screw the spindle in clockwise, as far as possible. In this position, the

maximum pressure is 81,5 kg/cm

2

(8,82 bar).

2. Gradually loosen by turning counterclockwise until reaching the

desired pressure. Each millimeter that the spindle sticks out

represents a reduction of approximately 9 kg/cm

2

(8,82 bar).

Pneumatic valve control

To adjust the pressure with this valve model, follow these steps:

1. Unlock the pressure regulator control by pulling on it gently.

2. Turn it clockwise to increase the pressure. This will be seen reflected

on the pressure gauge located next to it.

Loading...

Loading...