FOCKE MELER GLUING SOLUTIONS

5-8

MAINTENANCE

Recommended lubricants

BRAND TYPE OF OIL

IP Telesia Compound A

SHELL Tivela Compound A

MOBIL Glygoyle Grease 00

Safety Thermostat

If there is a deactivation of the thermostat, dismantle the tank casing with the

cover and slide the electrical cabinet along. When you can see the thermostat,

press the button indicated to reset it.

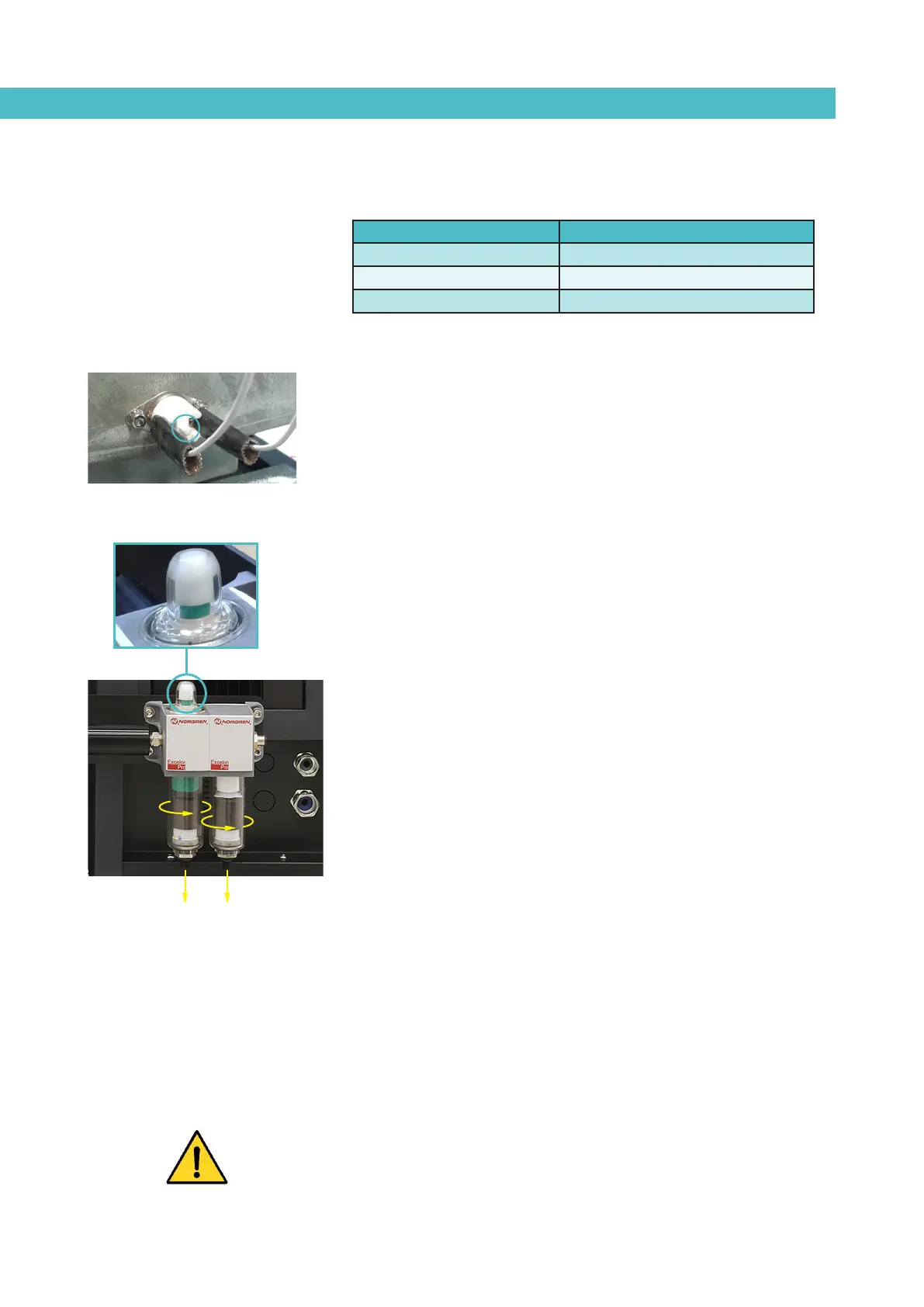

Air dryer filter maintenance

The filtering elements prior to the air dryer device on the melting equipment

are equipped with a filter saturation indicator, which indicates the best time to

change the filter cartrtidge:

- Green colour: Low level of cartridge contamination.

- Red colour: The cartridge is contaminated. Replace immediately,

otherwise equipment performance cannot be guaranteed.

We recommend installing new cartridges once a year, regardless of the

indicator reading (differential pressure).

Follow these steps to change the cartridge:

- Close the air valve.

- Release the drainage hose from the reservoir, if connected.

- Slowly turn the knurled screw clockwise. This will purge the air from

the filter.

- Push the reservoir towards the head of the filter.

- Slowly turn the reservoir clockwise as far as possible (1/8 of a turn)

and remove it, pulling down.

- Remove the cartridge and replace it with a new one (do not touch the

filter screen with your hands).

- Mount the reservoir, following these instructions in reverse order.

- Pressurize the filter, opening the by-pass valve slowly.

Warning: It is necessary to keep the power connected to the unit in order to

keep the air dryer system operational. The system may operate even with cold

adhesive, in order to keep the internal environment moisture-free.

0.01µm

5µm

automatic purge

Loading...

Loading...