FOCKE MELER GLUING SOLUTIONS

5-4

MAINTENANCE

Filter maintenance

Micron gear series melter equipment is equipped with a 50 mesh pump filter.

The filter prevents impurities and burnt adhesive remains from being pushed

out from the tank by the pump.

Warning: It is a good idea to also use a grill in the tank. This grill performs a

first-step filtration, preventing great impurities.

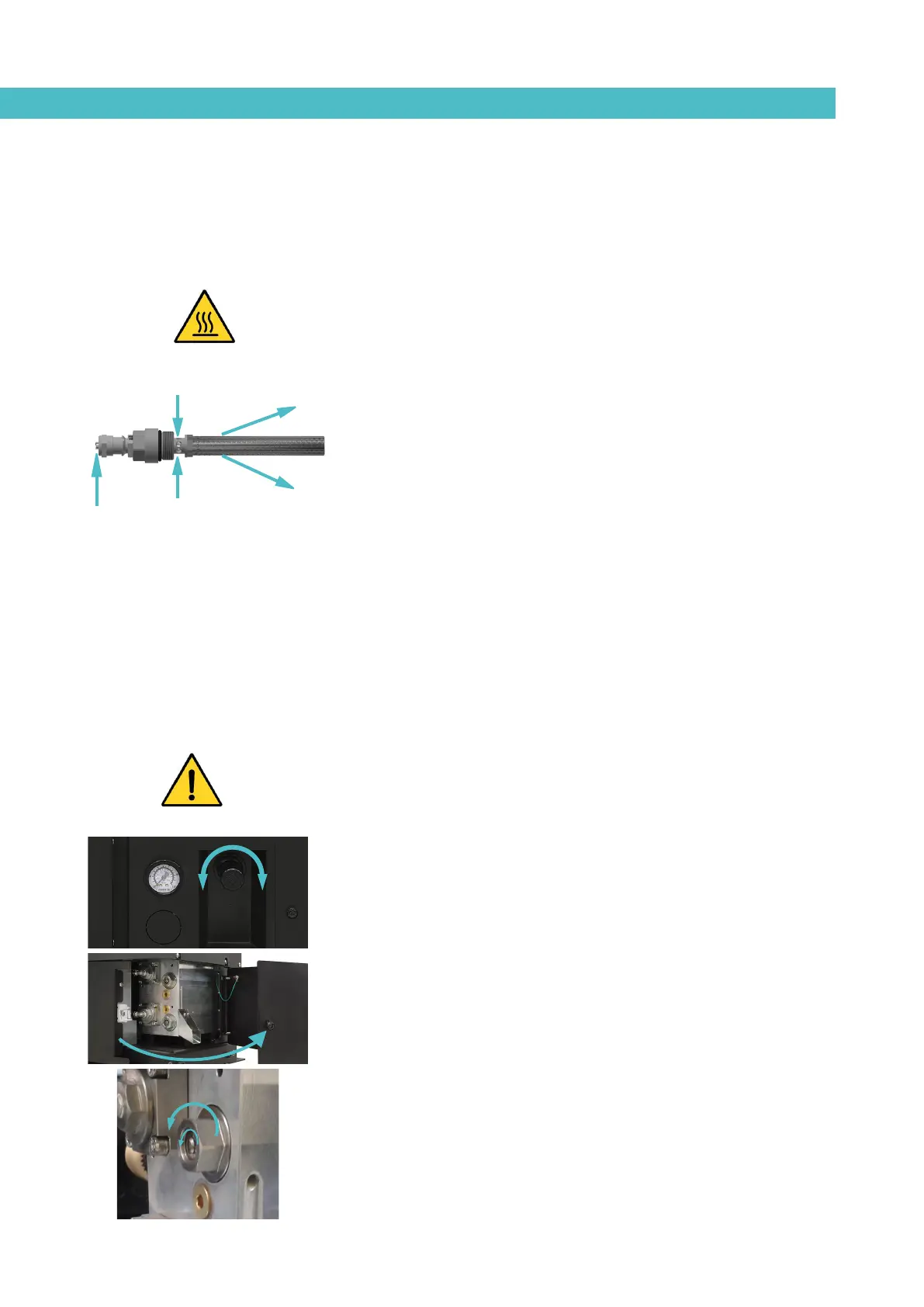

The adhesive flows from the inside to the outside of the filter, with impurities

being trapped inside it.

The drain valve is included in the filter cap.

When the filter is removed from its housing, all the impurities remain trapped

inside, and the inside of the distributor stays perfectly clean. The filter may be

cleaned or replaced directly with a new one.

No rule exists for determining when to change the filter. Several factors

influence this decision:

• The type and purity of the adhesives used.

• The adhesive work temperatures.

• Adhesive consumption in relation to the time it spends in the tank.

• Changes in the type of adhesive used.

In any case, we recommend checking and cleaning the filter at least every

1000 hours of operation (melter equipment turned on).

Warning: Always use protective gloves and goggles. Risk of burns.

To change the filter, it should be borne in mind that the filter and purge valve

are the same assembly:

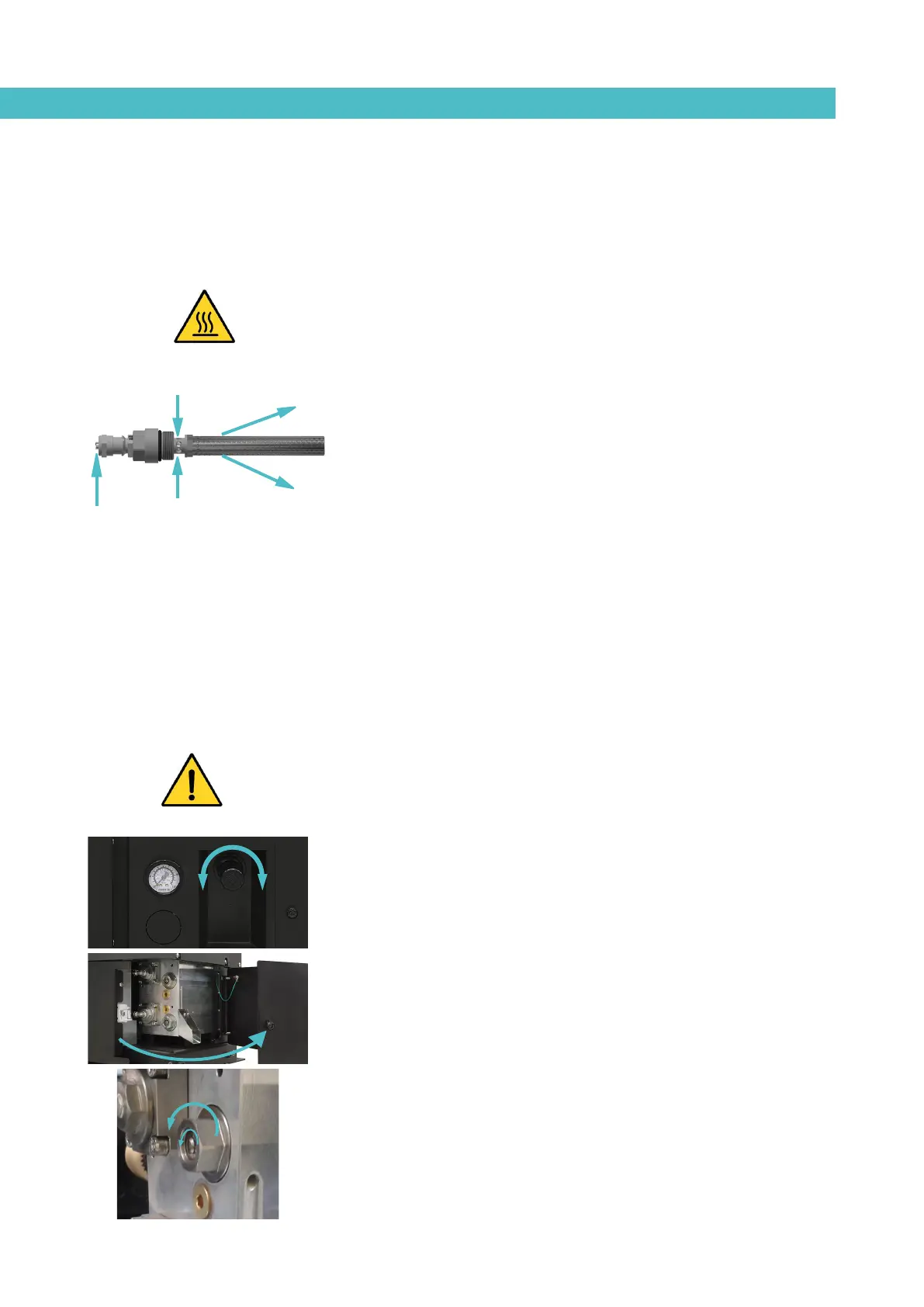

1. Depressurise the system and open the casing shown.

2. Using a flat blade screwdriver, open the drain valve contained in the

filter head anticlockwise (1) and wait until any remaining adhesive has

fallen down the ramp.

3. To remove the whole filter, unscrew the assembly’s hexagonal plug

using a 22 mm socket driver and remove it.

4. Depending on the amount of dirt inside the cartridge, clean it or throw

it away, following the applicable waste regulations.

5. Replace the joints if they are damaged.

6. Screw the assembly up again, clockwise.

1

2

purge zone

Loading...

Loading...