FOCKE MELER GLUING SOLUTIONS

4-2

MELTER OPERATION

Filling the tank

The tank may be equipped optionally with two types of detectors: capacitive or float

detectors. The capacitive detector issues a warning when the adhesive reaches the

programmed level, thanks to a low adhesive level signal. A float type detector issues

a warning when the molten hot-melt drops to one third of its capacity.

The unit will activate the external signal and, if it is connected, the

corresponding warning device.

Warning: Before refilling the tank, make sure that the adhesive is the same

type as that already in the tank. Mixing different types of adhesives can cause

damage to the melter equipment.

To fill the tank:

1. Open the tank lid.

2. Use a shovel or a ladle to fill the tank with adhesive. Do not fill the tank

above the loading opening level. The lid must be able to close normally.

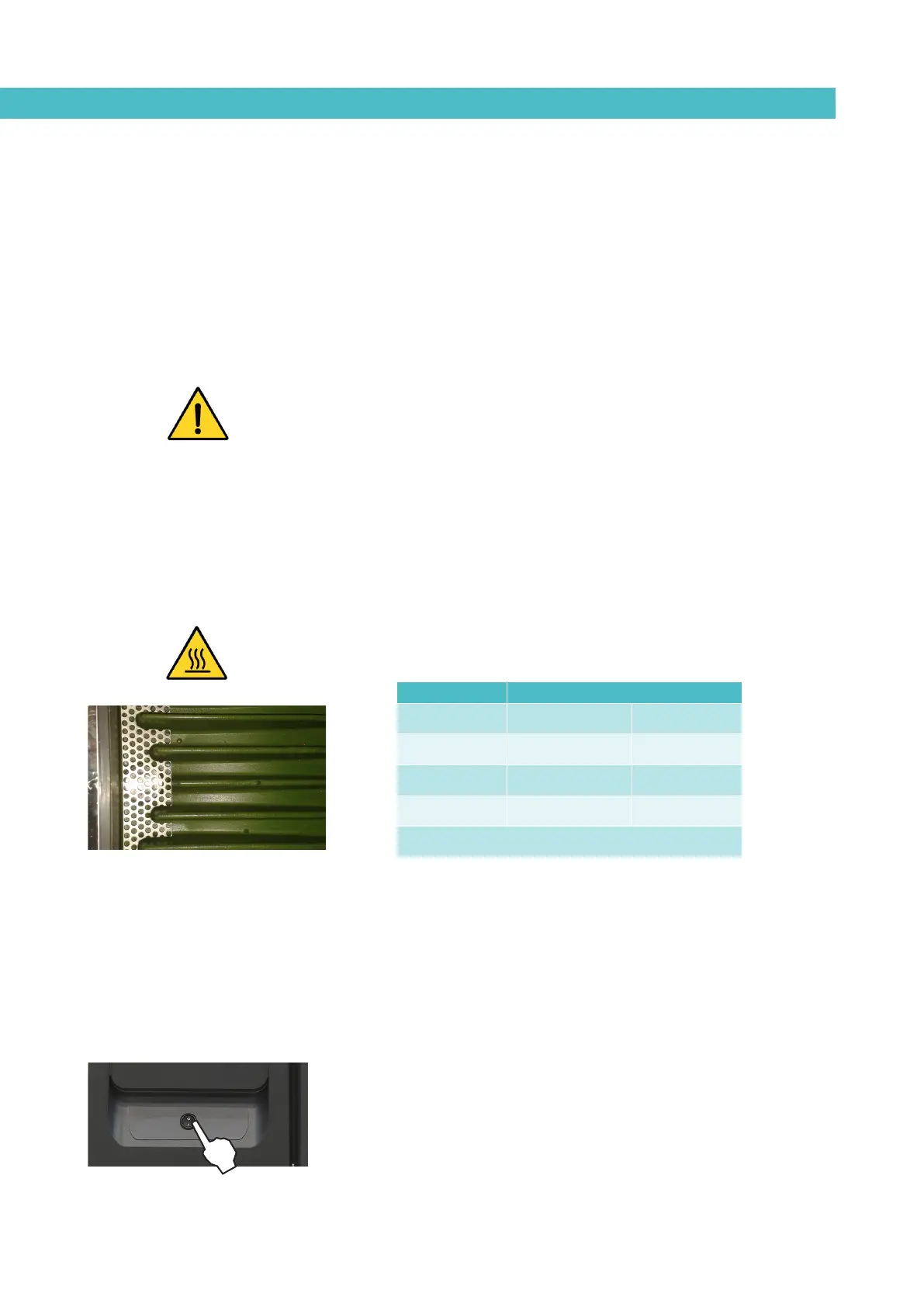

Warning: Risk of burns. Always refill using protective gloves and goggles.

3. Close the lid when you have finished refilling the tank.

Model Capacity

Micron5 5.15 L 5.15 kg

Micron10 9.7 L 9.7 kg

Micron20 19.7 L 19.7 kg

Micron35 37.4 L 37.4 kg

* for density of 1g/cm3

Starting up the melter equipment

Before starting up the melter equipment, it is necessary to check to see if

the unit has been correctly installed and all its input/output and accessory

connections are correctly established.

It is also necessary to make sure that the equipment has been filled with

adhesive and that the operational parameters have been programmed.

To start:

1. Connect the melter’s switch.

If the control card was turned off the last time the machine was disconnected,

it will remain tuned off when the machine is started up again (time display).

Loading...

Loading...