90-826148R2 MARCH 19973B-14 - FUEL SYSTEM

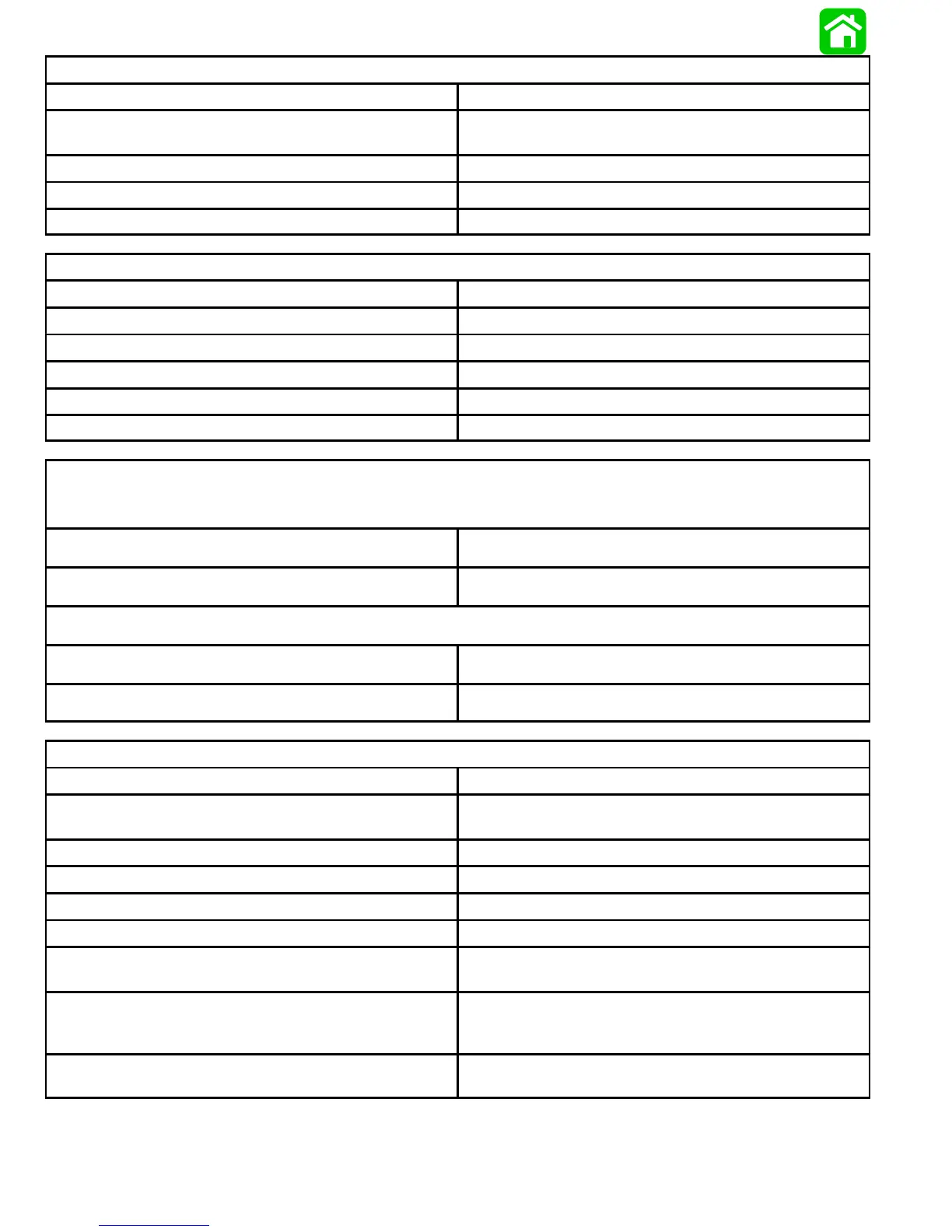

Problem: Engine Floods

Possible Cause Corrective Action

Dirt or debris are preventing inlet needle from seat-

ing.

Flush out inlet seat and clean inlet needle.

Worn inlet needle. Replace

Punctured float Replace.

Incorrect float setting Reset float.

Problem: Engine Runs Too Rich

Possible Cause Corrective Action

Fuel level too high. Reset float to correct level.

Carburetor floods. See preceding “Engine Floods.”

Idle nozzle air holes plugged. Blow out with compressed air.

Restricted air flow. Inspect cowl air inlet and carburetor for obstructions.

Main fuel jet loose. Re-tighten jet.

Problem: Fuel Blow back Out of Carburetor

Problem: Unable to Reduce Engine RPM to Slow Idle

Possible Cause Corrective Action

Chipped or broken reeds on reed block. Replace reeds.

Problem: Rough Idle

Possible Cause Corrective Action

Excessive pre-load on reeds. Replace reeds.

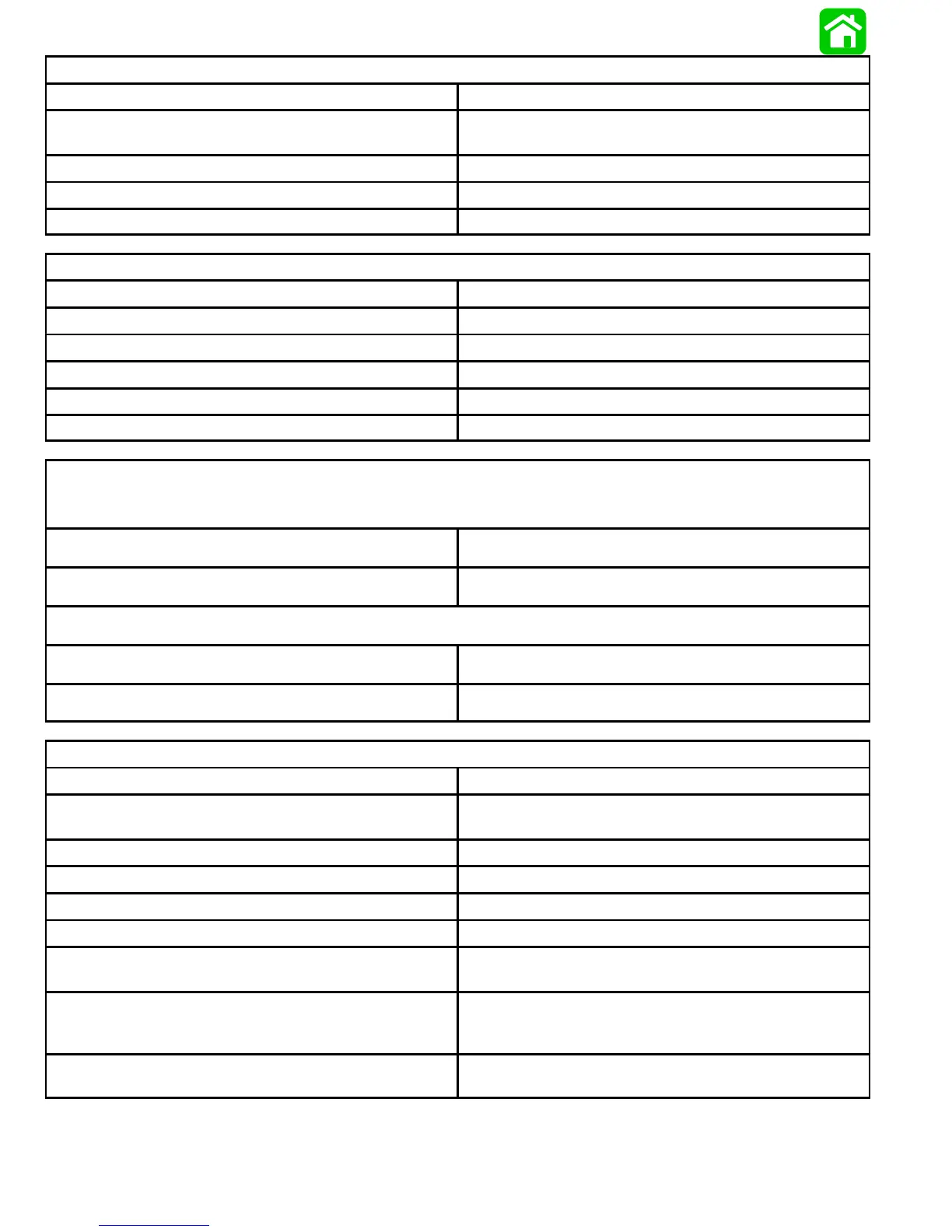

Problem: Engine Runs Too Lean

Possible Cause Corrective Action

Carburetor is loose. Air leaks past mixing chamber

cover.

Tighten bolts securely. Tighten cover or replace gas-

ket.

Fuel level is too low. Reset float level.

Clogged high speed jet. Inspect jet for varnish or debris and clean.

Restricted fuel flow to carburetor. Check fuel lines and filter(s) for restricted flow.

Incorrect high speed jet. Refer to main jet chart and replace with proper jet.

Idle mixture set too lean. Adjust to run richer (turn idle mix screw counter-

clockwise).

Air leakage into fuel system. Inspect fuel line connections, hose clamps, fuel

pump and fuel outlet tube (located in fuel tank) for

loose fittings.

Anti-siphon valve restricting fuel flow. Refer to Section 3B for checking for restriction of

fuel flow caused by anti-siphon valve.

Loading...

Loading...