POWERHEAD - 4-2190-826148R2 MARCH 1997

REASSEMBLY S/N 0G380074 & BELOW

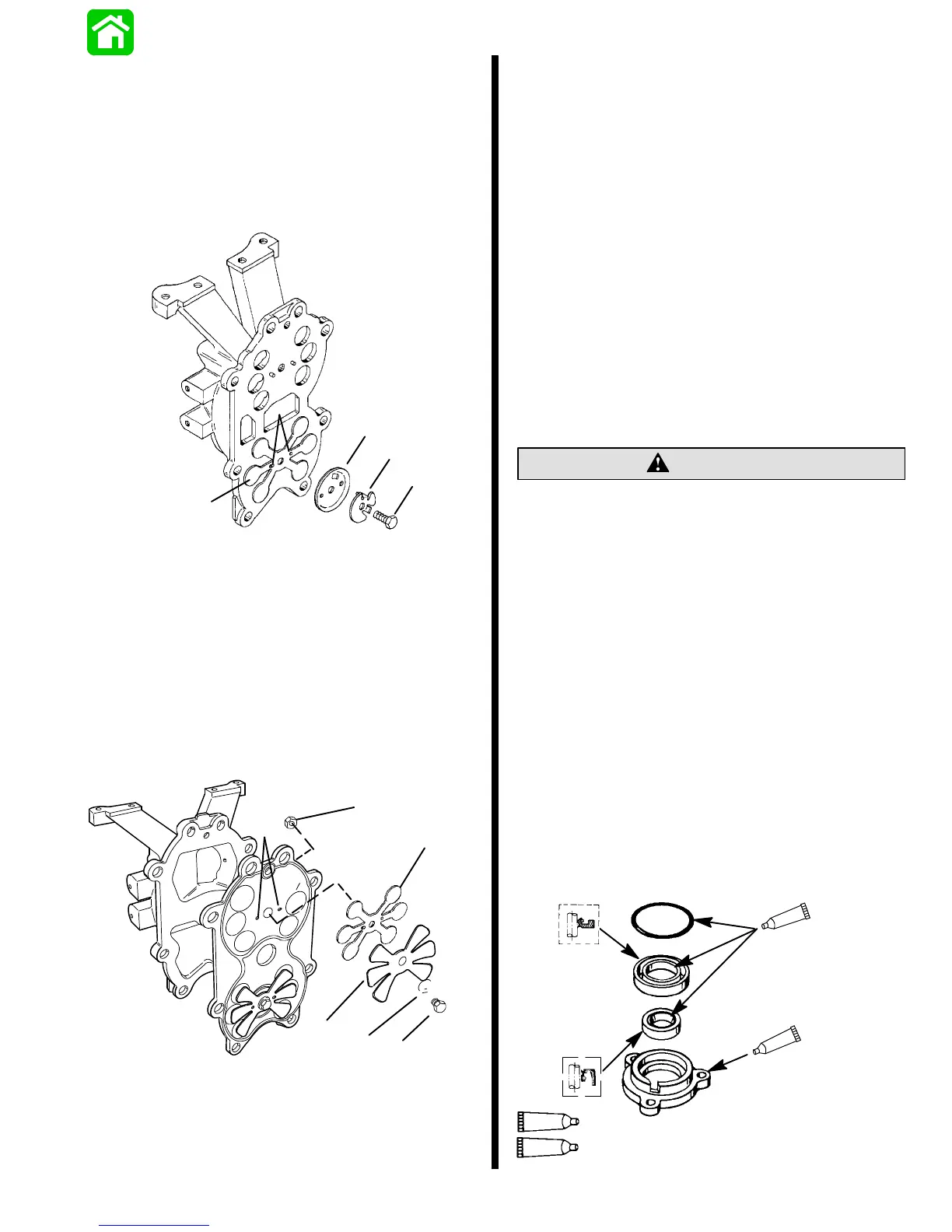

If reed block was disassembled, reassemble by lo-

cating reeds on pins with retaining washer. Using

new tab washer, insert bolt and torque to 60 lb. in.

(6.8 N·m); then, if necessary, continue the torque to

align flaton hex-head to locking tab (e).DO NOT ex-

ceed100lb.in.(11.3N·m)oftorque.Benduplocktab

to secure bolt position.

52896

a

b

c

d

e

a - Reed

b - Pins

c - Retaining Washer

d - Tab Washer

e - Bolt - Torque to 60 lb. in. (6.8 N×m)

REASSEMBLY S/N 0G380075 & ABOVE

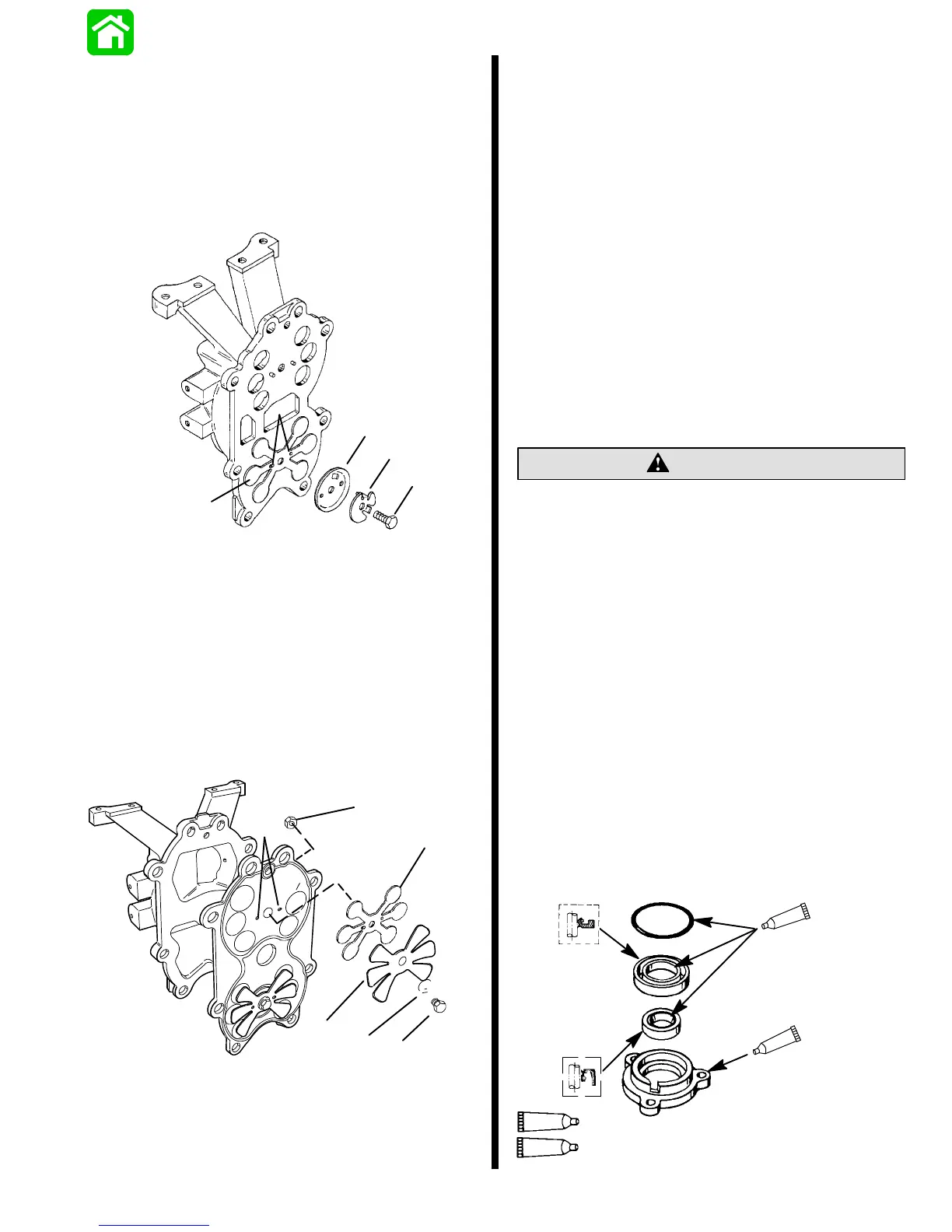

If reed block was disassembled, reassemble by lo-

cating reeds and reed stops on pins. Secure to reed

plate with bolt, washer, and nut. Torque to 60 lb. in.

(6.8 N·m).

a

b

c

d

e

f

a - Reeds

b - Locating Pins

c - Reed Stops

d - Washer

e - Bolt

f - Nut

Powerhead Reassembly and

Installation

General Information

Before proceeding with powerhead reassembly, be

sure that all parts to be reused have been carefully

cleaned and thoroughly inspected, as outlined in

“Cleaning and Inspection”. Parts, which have not

been properly cleaned (or which are questionable),

can severely damage an otherwise perfectly good

powerheadwithinafewminutesofoperation.Allnew

powerhead gaskets must be installed during assem-

bly.

During reassembly, lubricate parts with Quicksilver

2-Cycle Outboard Oil whenever 2-cycle oil is speci-

fied, and Quicksilver 2-4-C Marine Lubricant when-

ever grease is specified.

CAUTION

Any GREASE used for bearings INSIDE the pow-

erhead MUST BE gasoline soluble. Use only

QuicksilverNeedleBearing AssemblyLubricant.

DO NOT use 2-4-C Marine Lubricant, or other lu-

bricants inside the powerhead, or damage may

occur.

A torque wrench is essential for correct reassembly

of powerhead. Do not attemptto reassemble power-

head without using a torque wrench.

End Cap

1. Clean thoroughly, including seal and O-ring

seats; remove Perfect Seal residue and clean

cap-to-head mating surface.

2. Using suitable mandrel, press oil seals into cap

until fully seated.

NOTE: Lip of smaller seal faces away from power-

head. Lip of larger seal faces towards powerhead.

A

Perfect Seal (92-34227-1)

K

K

52683

A

2-4-C w/Teflon (92-825407A12)

Loading...

Loading...