POWERHEAD - 4-1790-826148R2 MARCH 1997

CAUTION

If crankcase cover and cylinder block is to be

submerged in a very strong cleaning solution, it

willbenecessarytoremovethecrankcasecover/

cylinder block bleed system from cover/cylinder

block to prevent damage to hoses and check

valves.

Cylinder Bores

1. Inspect cylinder bores for scoring, scuffing or a

transfer of aluminum from piston to cylinder wall.

Scoring or scuffing, if NOT TOO SEVERE, can

normally be removed by honing. If a transfer of

aluminum has occurred, an acidic solution such

as“TIDYBOWLCLEANER”shouldbeappliedto

the areas of the cylinder bore where transfer of

aluminum has occurred. After the acidic solution

has removed the transferred aluminum,

thoroughly flush the cylinder bore(s) to remove

any remaining acid. Cylinder walls may now be

honed to remove any glaze and to aid in the

seating of new piston rings.

HONING PROCEDURE

a. When cylinders are to be honed, follow the

hone manufacturer’s recommendations for

use of the hone and cleaning and lubrication

during honing.

b. For best results, a continuous flow of honing

oil should be pumped into the work area. If

pumping oil is not practical, use an oil can.

Apply oil generously and frequently on both

stones and work area.

CAUTION

When honing cylinder block, remove hone fre-

quently and check condition of cylinder walls.

DO NOT hone any more than absolutely neces-

sary, as hone can remove cylinder wall material

rapidly.

c. Start stroking at smallest diameter. Maintain

firm stone pressure against cylinder wall to

assure fast stock removal and accurate re-

sults.

d. Localizestrokinginthesmallestdiameterun-

til drill speed is constant throughout length of

bore. Expand stones, as necessary, to com-

pensate for stock removal and stone wear.

Stroke at a rate of 30 complete cycles per

minute to produce best cross-hatch pattern.

Use honing oil generously.

e. Thoroughly clean cylinder bores with hot wa-

ter and detergent. Scrub well with a stiff

bristle brush and rinse thoroughly with hot

water. A good cleaning is essential. If any of

the abrasive material is allowed to remain in

the cylinder bore, it will cause rapid wear of

newpistonringsand cylinderbore inaddition

to bearings. After cleaning, bores should be

swabbed several times with engine oil and a

cleancloth,thenwipedwithaclean,drycloth.

Cylinders should not be cleaned with kero-

seneorgasoline.Cleanremainderofcylinder

block to remove excess material spreaddur-

ing honing operation.

2. Hone all cylinder walls just enough to de-glaze

walls.

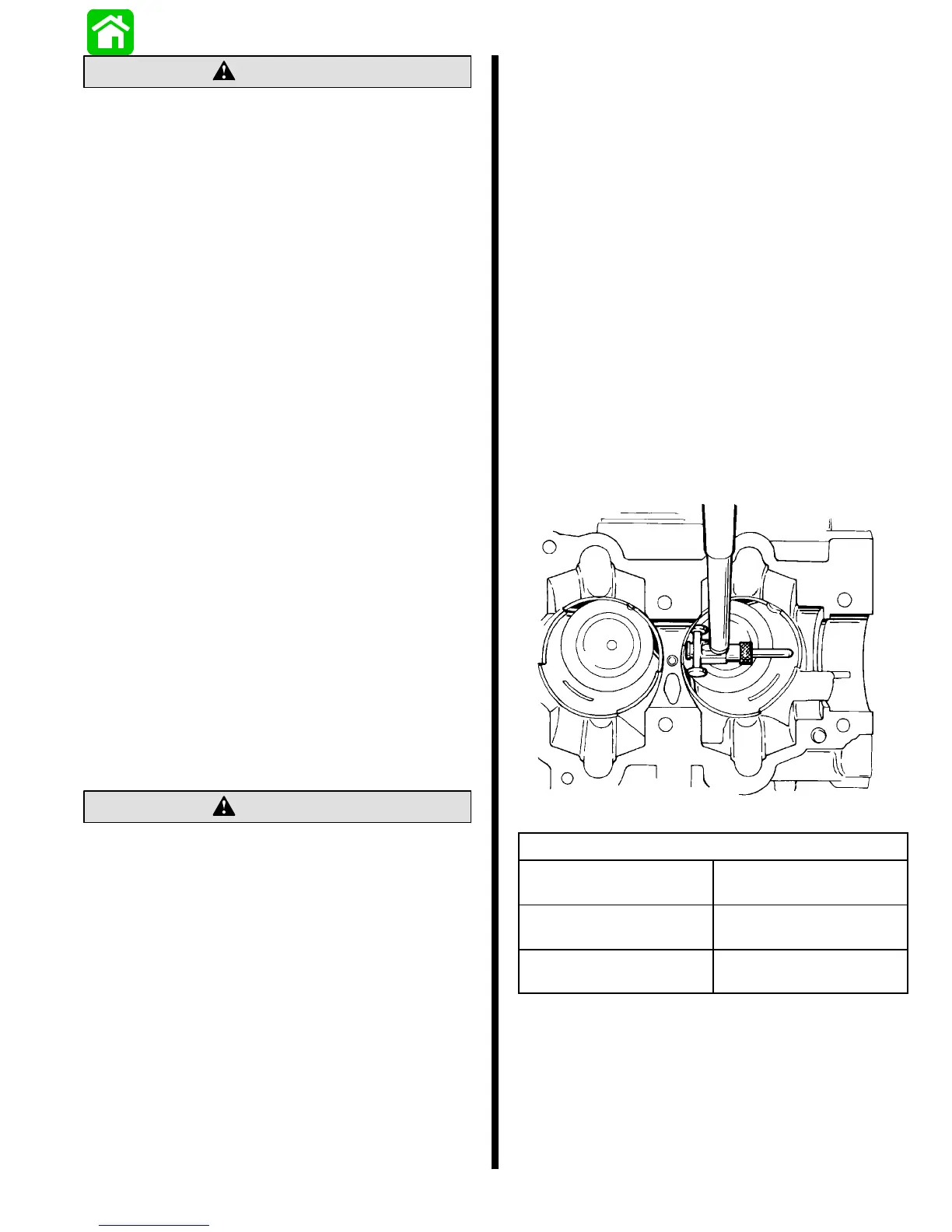

3. Measure cylinder bore diameter (with a snap

gauge micrometer) at top, middle and bottom of

each cylinder, as shown below. Check for

tapered, out-of-round (egg-shaped) and

oversize bore.

52886

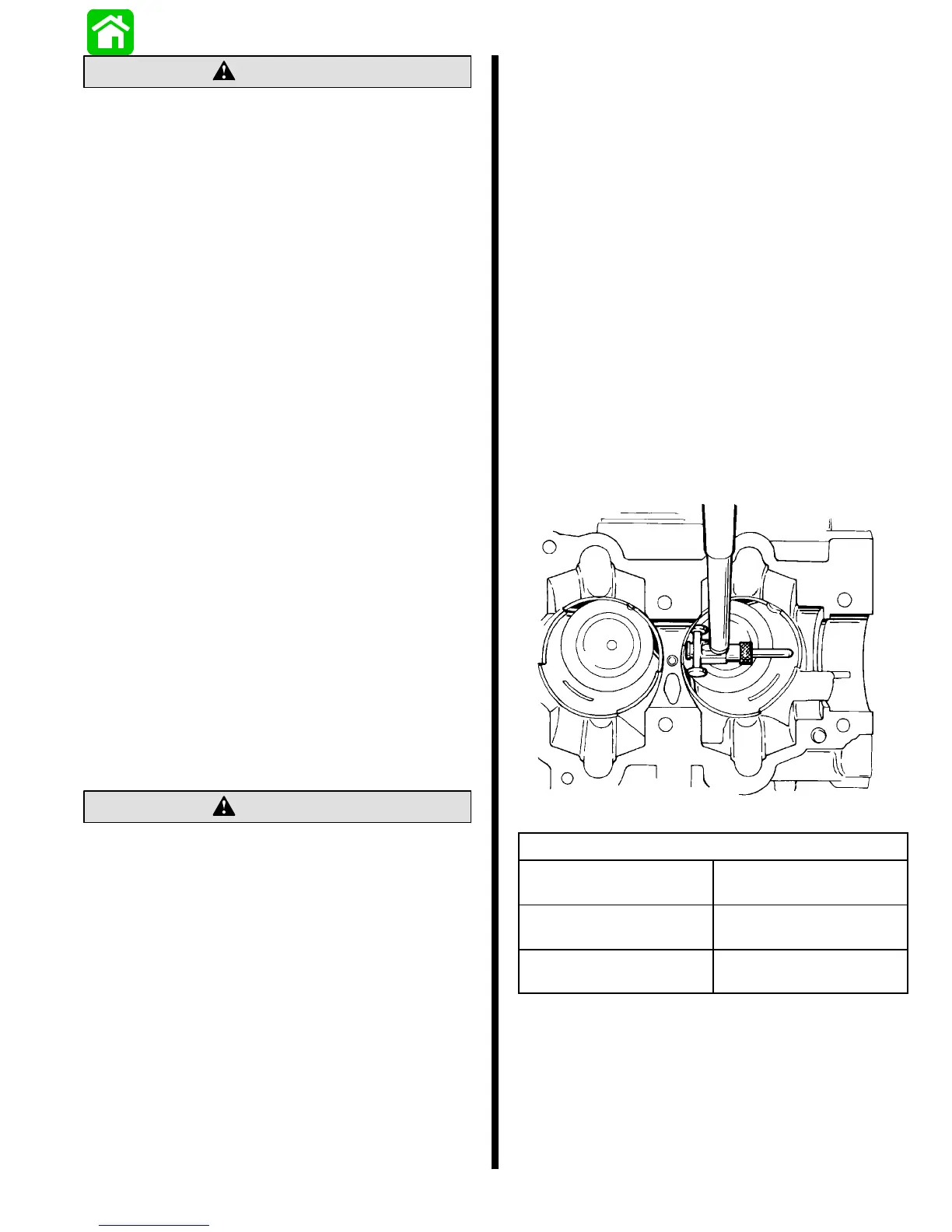

CYLINDER BORE SIZE

PISTON SIZE CYLINDER BLOCK

FINISH HONE

Standard Diameter 2.993 in.

76.022 mm

.015 Oversize 3.007 in.

76.38 mm

4. If a cylinderbore istapered,out-of-roundor worn

more than 0.003 in. (0.076mm) from standard

“Cylinder Block Finish Hone” diameter (refer to

chart, preceding), it will be necessary to re-bore

that cylinder(s) to 0.015 in. (0.381mm) oversize

or re-sleeve and install oversize piston(s) and

piston rings during reassembly.

Loading...

Loading...