MAINTENANCE

Milli-Q Synthesis/Synthesis A10 57

Chapter 6 MAINTENANCE

6-1 MAINTENANCE SCHEDULE

See the Maintenance Guide below for the typical maintenance that needs to be performed on your

Milli-Q Synthesis or Milli-Q Synthesis A10. The Catalogue Numbers and other ordering information can be found

in Sections 8-1 and 8-2. Detailed information about the various consumable items can be found in Sections 2-2

and 2-3.

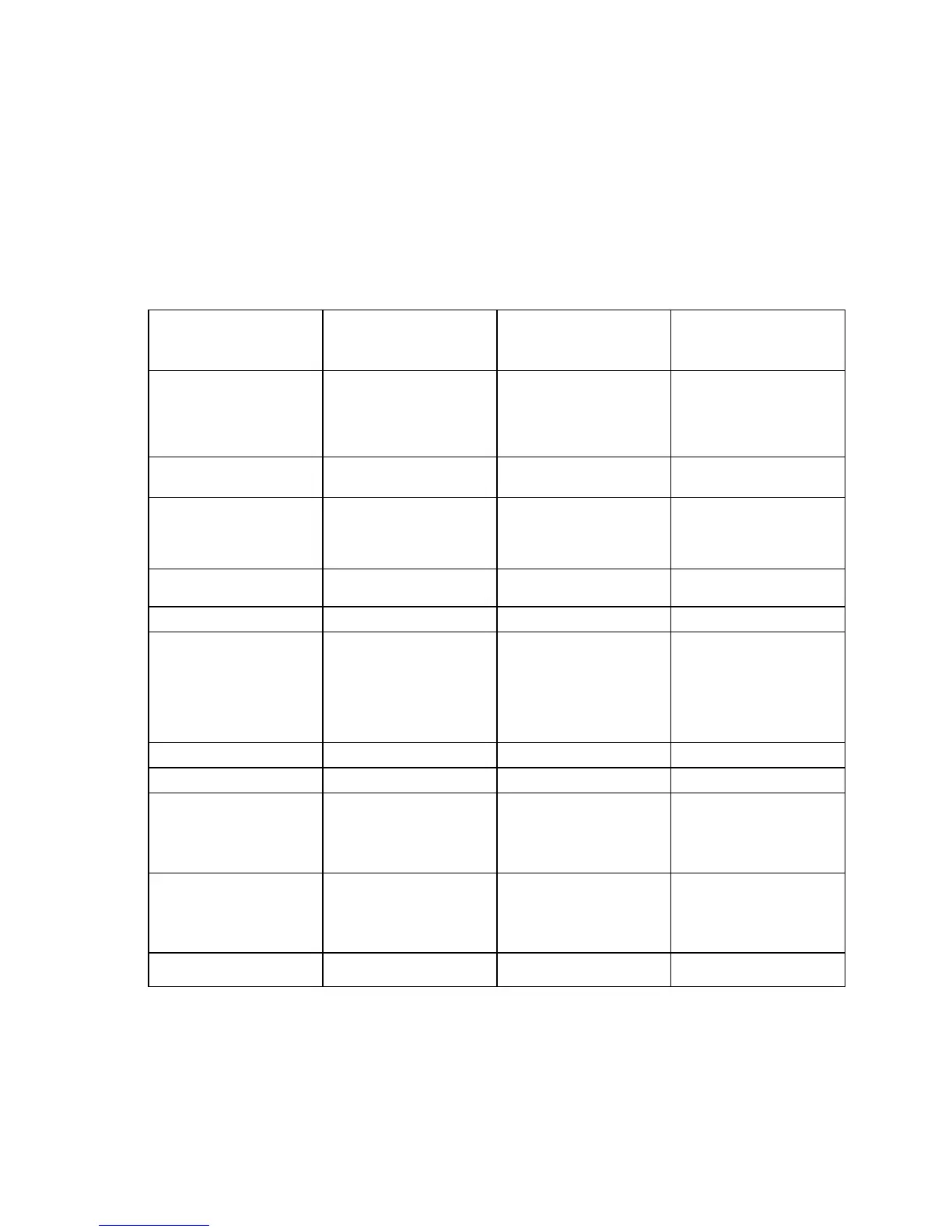

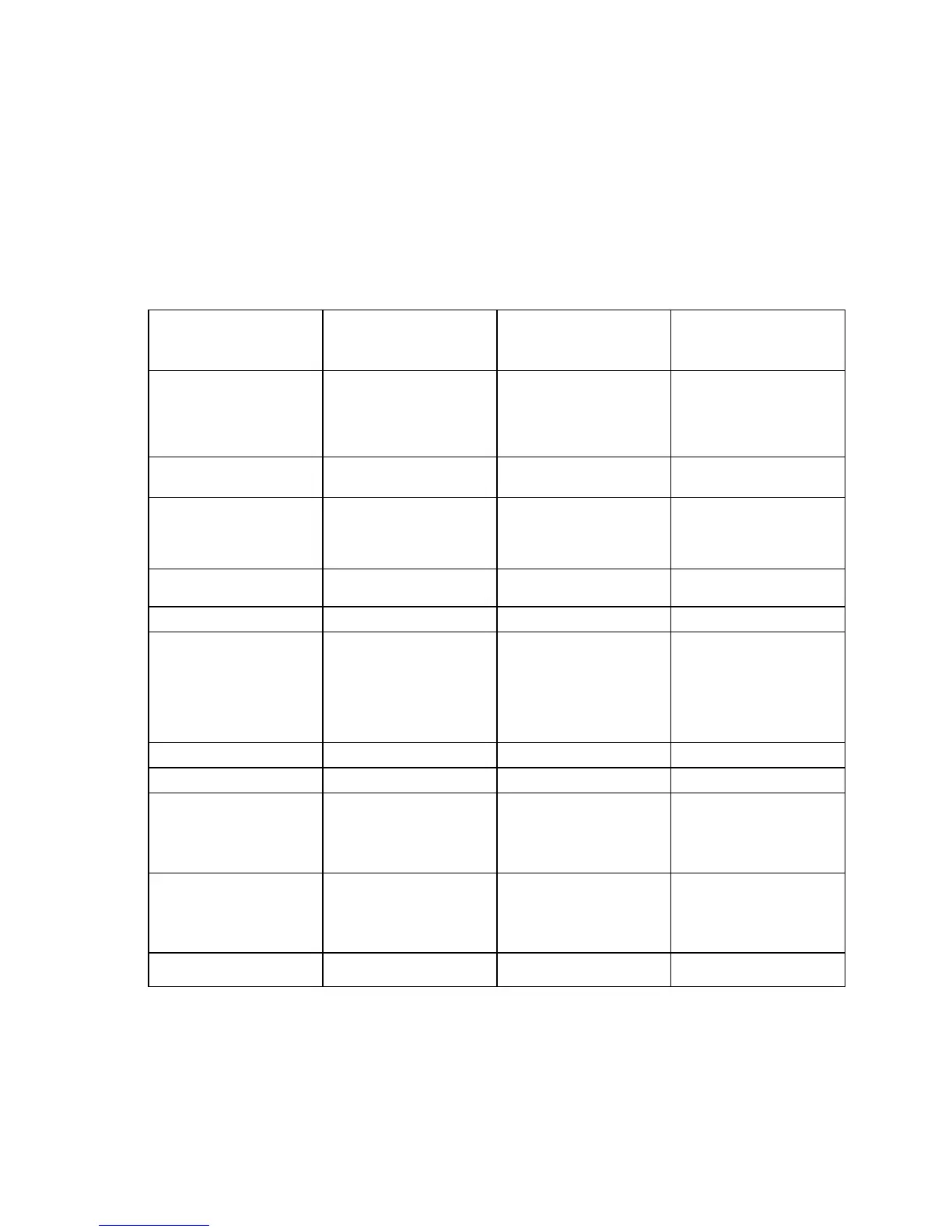

Item or action Maintenance

needed

When? How to?

Q-Gard Pack

Replacement When the system resistivity or

TOC values are outside of

specification or the EXCH.

CARTRIDGE message is

displayed.

See Section 6-2

Quantum Cartridge

Replacement Replace when the Q-Gard Pack

is replaced.

See Section 6-3

Millipak

Replacement Replaced when the Quantum

Cartridge and Q-Gard Pack are

replaced or when the Product

Water Flowrate drops.

See Section 6-4

Sanitisation and cleaning of

the UF Cartridge

Cleaning Every 4 weeks. See Section 6-5

Screen Filter

Cleaning 2 times a year or as necessary. See Section 6-6

Flow Calibration

Perform a calibration

When the Millipak is

replaced.

After an AIR PURGE

After a ‘dirty’ UF Cartridge

is cleaned

Periodically.

See Section 4-11

POU Dispenser Arm

Tightening As necessary. See Section 6-7

A10 UV

Replacement Every 365 Days. See Section 6-8

A10 Cleaning

Perform a cleaning Automatic when the Quantum is

replaced.

----------------------------------

As necessary.

See Section 6-9

Air Purge of UF Cartridge

Perform an Air Purge Automatic when the Quantum is

replaced.

----------------------------------

As necessary.

See Section 6-10

UV Lamp

Replacement Every 365 Days See Section 6-11

Loading...

Loading...