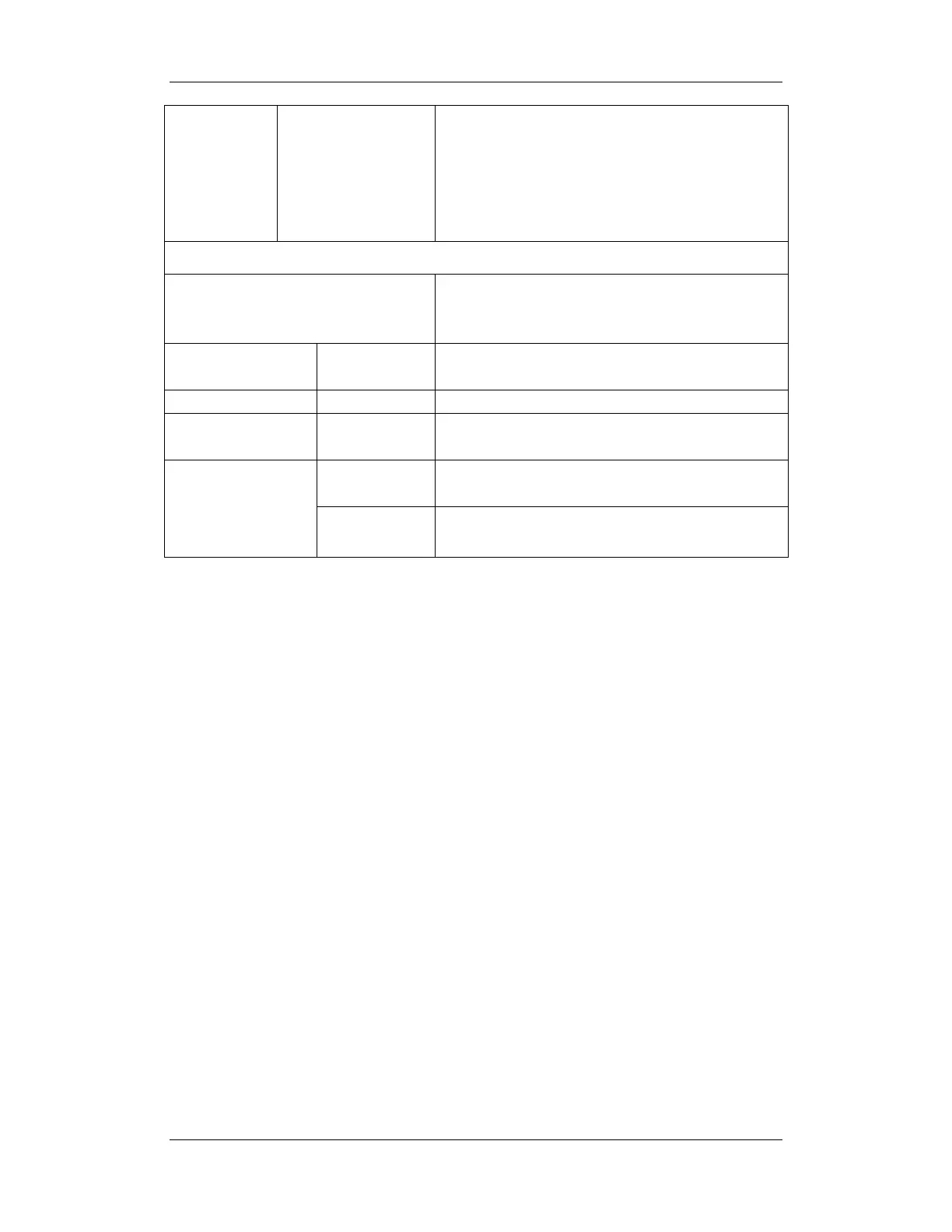

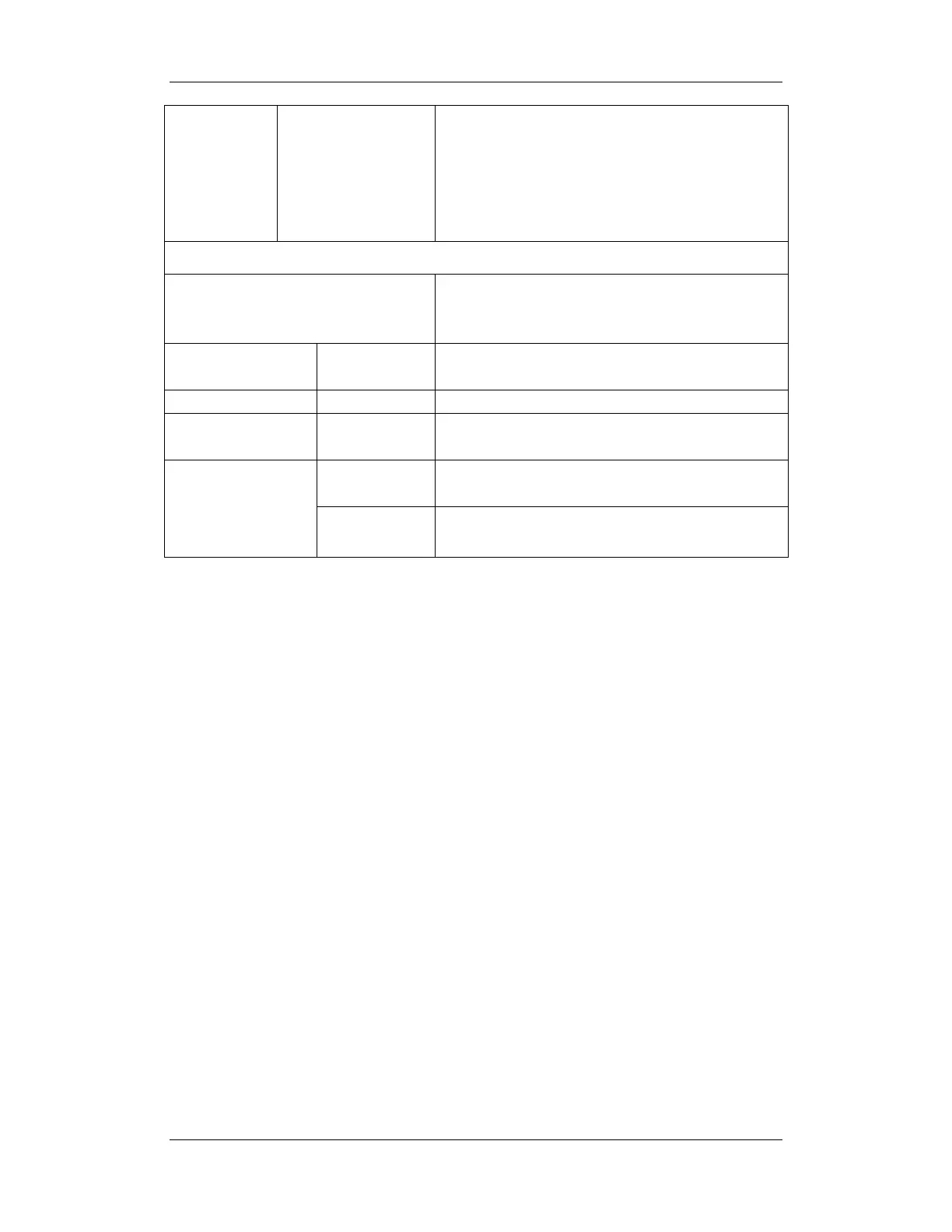

3-4

Electrical

safety tests

Refer to A Electrical

Safety Inspection.

1. Following any repair or replacement

2. After the monitor drops.

3. At least once every two years.

Other Tests

Power on test

1. When first installed or reinstalled.

2. Following any maintenance or the replacement of

any main unit parts.

Touchscreen

calibration

/

1. When the touchscreen appears abnormal.

2. After the touchscreen is replaced.

Recorder check / Following any repair or replacement of the recorder.

Network print test /

1. When first installed.

2. Whenever the printer is serviced or replaced.

Functionality

test

1. When first installed.

2. Whenever a battery is replaced.

Battery check

Performance

test

Once a year or if the battery run time reduced

significantly.

3.2 Preventative Maintenance Procedures

3.2.1 Visual Inspection

Inspect the equipment for obvious signs of damage. The test is passed if the equipment has no

obvious signs of damage. Follow these guidelines when inspecting the equipment:

Carefully inspect the case, display screen, buttons and knob for obvious signs of

damage.

Inspect the SMR and parameter modules for obvious signs of damage.

Inspect the power cord, wall-mount bracket and module accessories for obvious signs of

damage

Inspect all external connections for loose connectors, bent pins or frayed cables.

Inspect all connectors on the equipment for loose connectors or bent pins.

Make sure that safety labels and data plates on the equipment are clearly legible.

Loading...

Loading...