4G1 ENGINE (E–W) – Alternator and Ignition System

11A-3-5

PWEE9520

E

Nov. 1995Mitsubishi Motors Corporation

REMOVAL SERVICE POINT

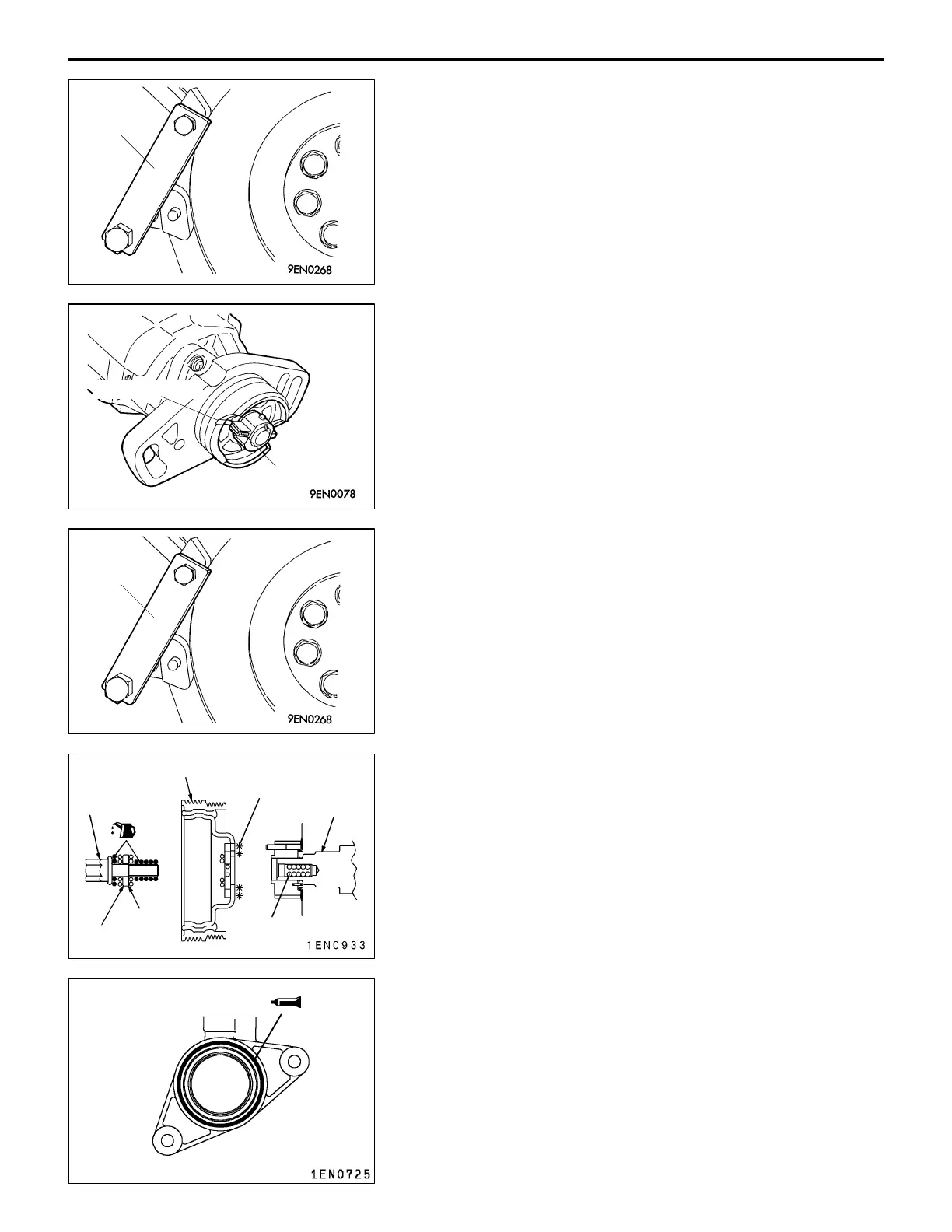

AA" CRANKSHAFT BOLT REMOVAL

(1) Lock the flywheel or drive plate in position using the special

tool shown in the illustration, then loosen the crankshaft

bolts.

INSTALLATION SERVICE POINTS

"AA DISTRIBUTOR INSTALLATION

(1) Turn the crankshaft clockwise until cylinder No. 1 is at

top dead center on its compression stroke.

(2) Align the alignment marks on the distributor housing and

coupling.

(3) Fit the distributor onto the engine, aligning the stud bolts

with the slots in the distributor mounting flange.

"BA CRANKSHAFT PULLEY / BOLT INSTALLATION

(1) Hold the flywheel or drive plate using the special tool.

(2) Clean the bolt hole in crankshaft, crankshaft bolt and

crankshaft pulley’s seating surface.

(3) Degrease the cleaned seating surface of the crankshaft

pulley.

(4) Install the crankshaft pulley.

(5) Apply oil to the threads of crankshaft bolt and the outer

surface of washer.

(6) Tighten the crankshaft bolt to the specified torque of 125

Nm.

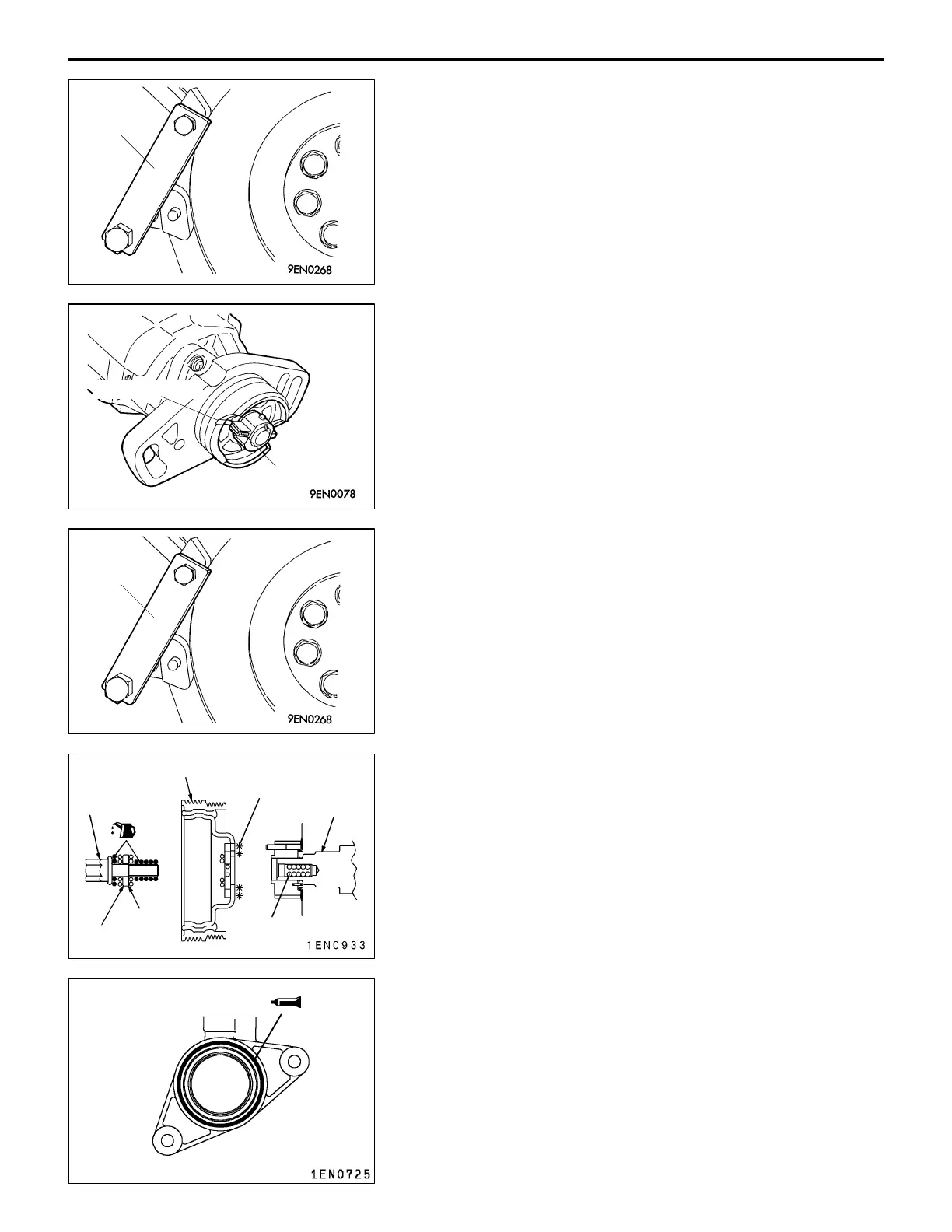

"CA CAM POSITION SENSOR SUPPORT

INSTALLATION

(1) Apply a 3 mm bead of form-in-place gasket (FIPG) to

the area shown.

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent

PWEE9520-F

E

Aug. 2001Mitsubishi Motors Corporation Revised

MD998781

Alignment mark

Alignment mark

MD998781

Crankshaft pulley

Crankshaft

bolt

Washer

Degrease

Crankshaft

Clean

Shear-drop

Loading...

Loading...