FUEL SYSTEM

8-10

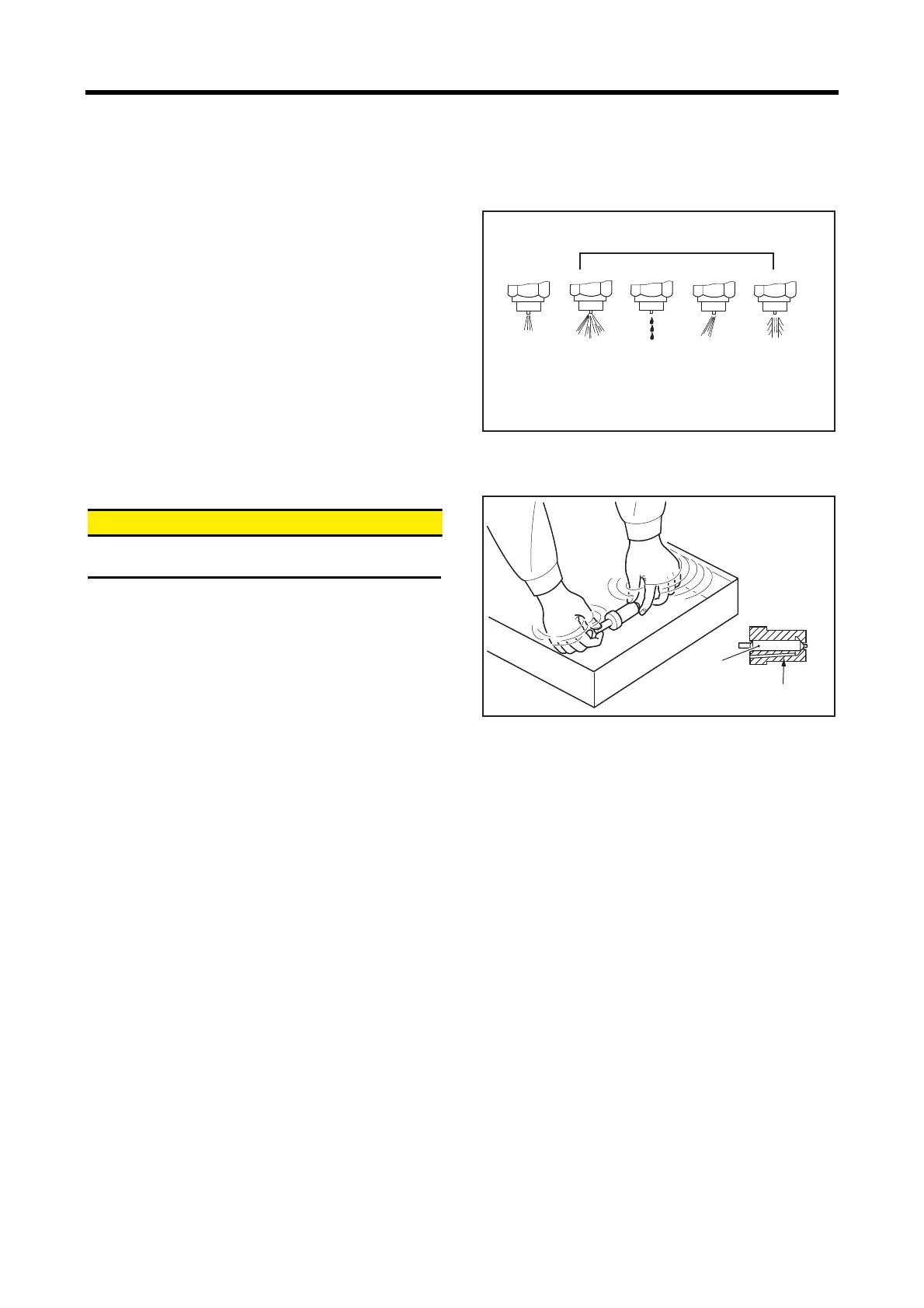

2.1.2 Inspecting fuel spray pattern of fuel injec-

tion nozzle

(1) When adjusting the nozzle opening pressure using the

nozzle tester, check for nozzle hole condition, and fuel

spray pattern.

(2) Checking points of fuel spray are as follows:

· Fuel is injected from all spray holes simultaneously.

· Fuel is injected conically at the specified spray angle.

· Fuel is injected in a spray of fine droplets.

· Fuel is injected without after-dribbling.

(3) If spray condition is faulty, clean or replace the nozzle

tip.

Checking fuel spray pattern from fuel injection nozzle

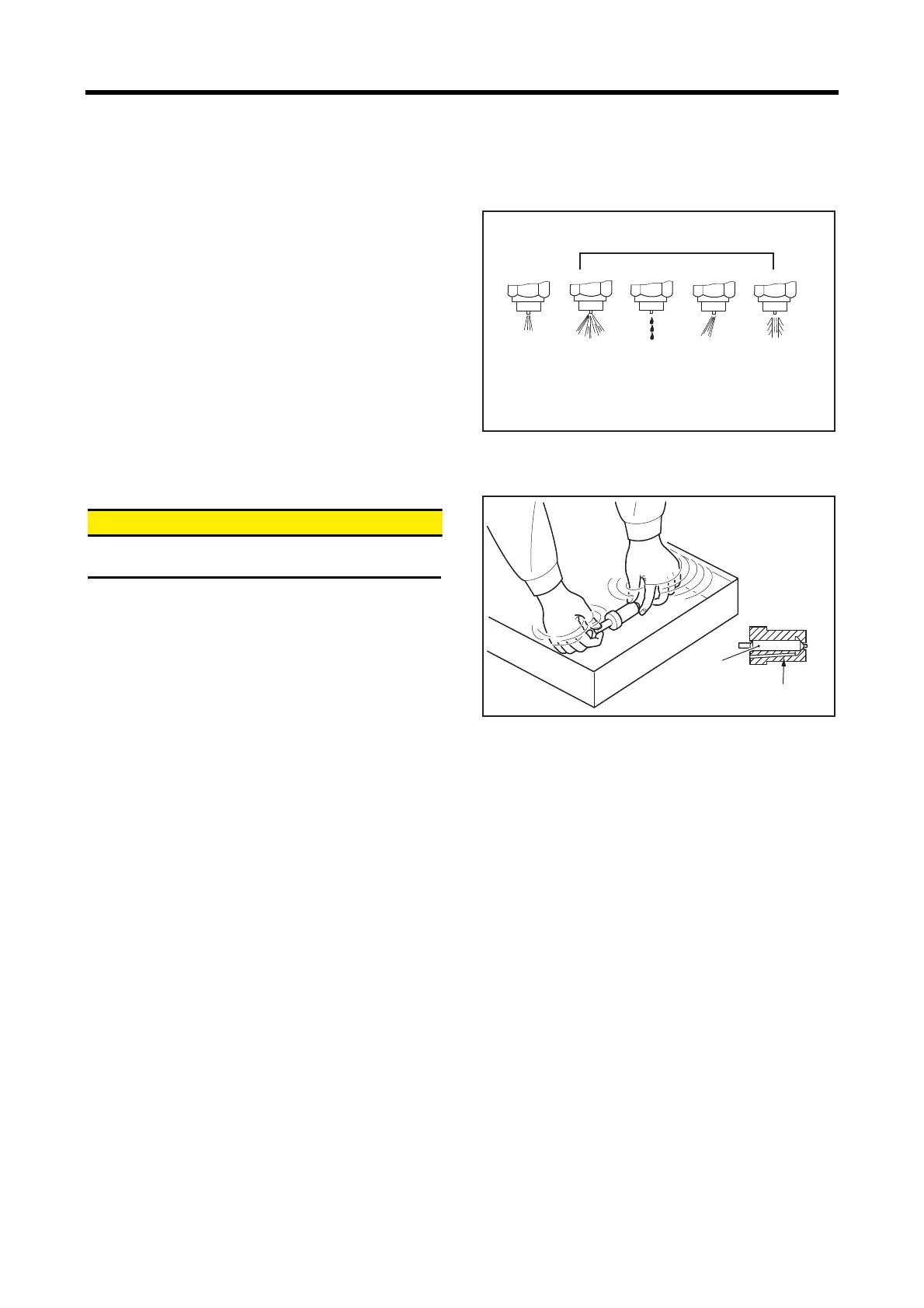

2.1.3 Cleaning and replacing faulty nozzle

&$87,21

When pulling out the nozzle tip, be careful not to dam-

age the tip.

(1) Loosen the retaining nut, then remove the nozzle tip,

and clean the needle valve and body.

(2) Clean the nozzle tip in clean wash oil. After cleaning,

assemble the needle valve and body in clean diesel fuel.

Note: The needle valve and body are precision parts.

Handle them carefully, and do not change the

combination of the valve and body.

(3) Tighten the nozzle tip retaining nut to the specified

torque.

(4) If the spray pattern is still faulty after cleaning and

adjusting, replace the nozzle tip.

Note: When using a new nozzle tip, remove the anti-

corrosive agent from the nozzle tip, and clean the

nozzle tip in wash oil. Then clean the tip again in the

fuel before assembly.

Cleaning nozzle tip assembly

Good

Large

spray

angle

After

dribble

Branched

spray

Deflected

spray

Defective spray pattern

Needle

valve

Body

Loading...

Loading...