INSPECTION AND REPAIR OF BASIC ENGINE

6-17

4.9 Measuring clearance between main bear-

ing and crankshaft journal

&$87,21

(a) When grinding crank journals, be sure to grind all

the journals to the same size.

(b) Finish the fillet radius to the specified dimension.

(1) Reassemble main bearings.

(2) Tighten the main bearing caps to the specified torque.

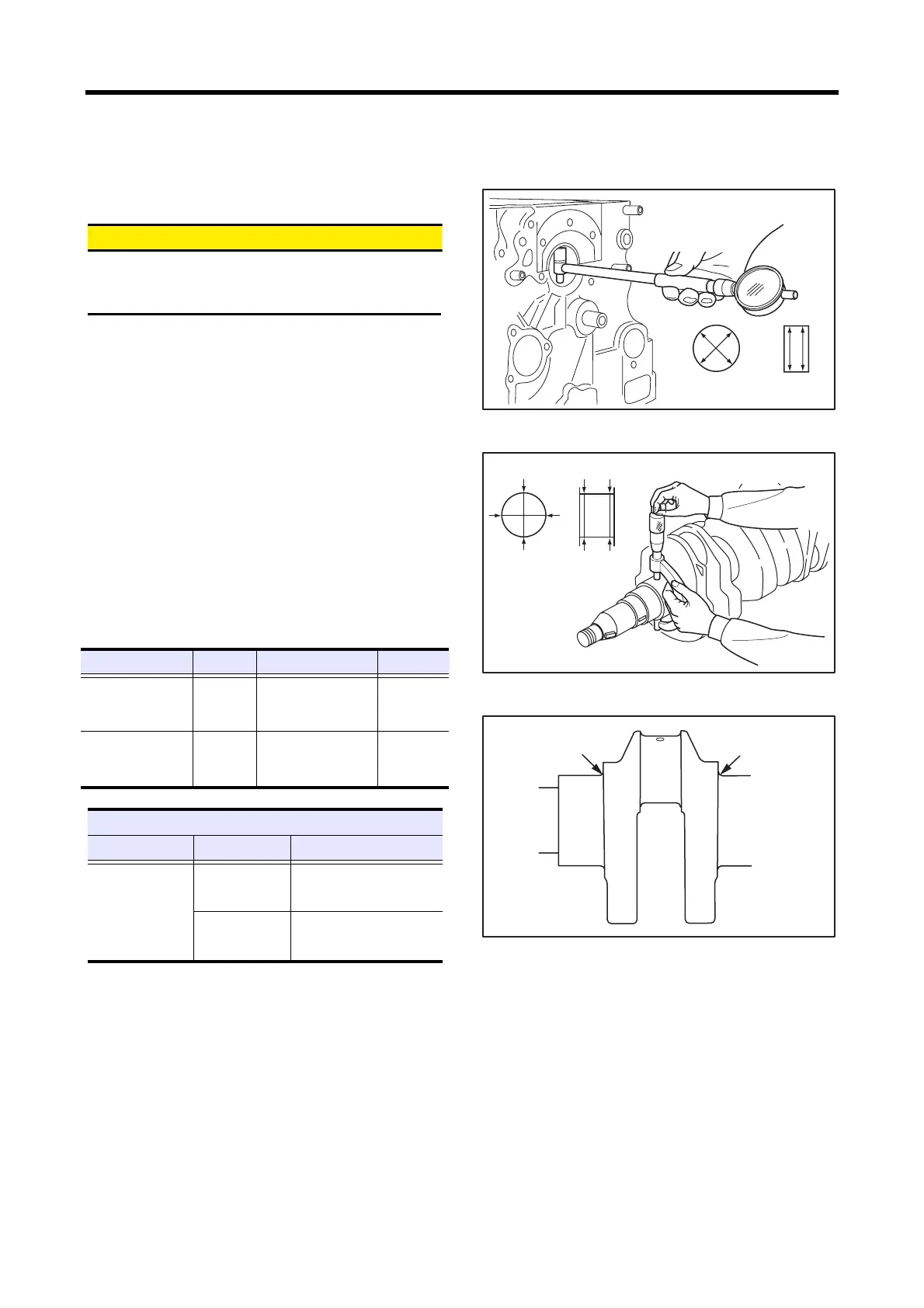

(3) Measure the inside diameter of the main bearings.

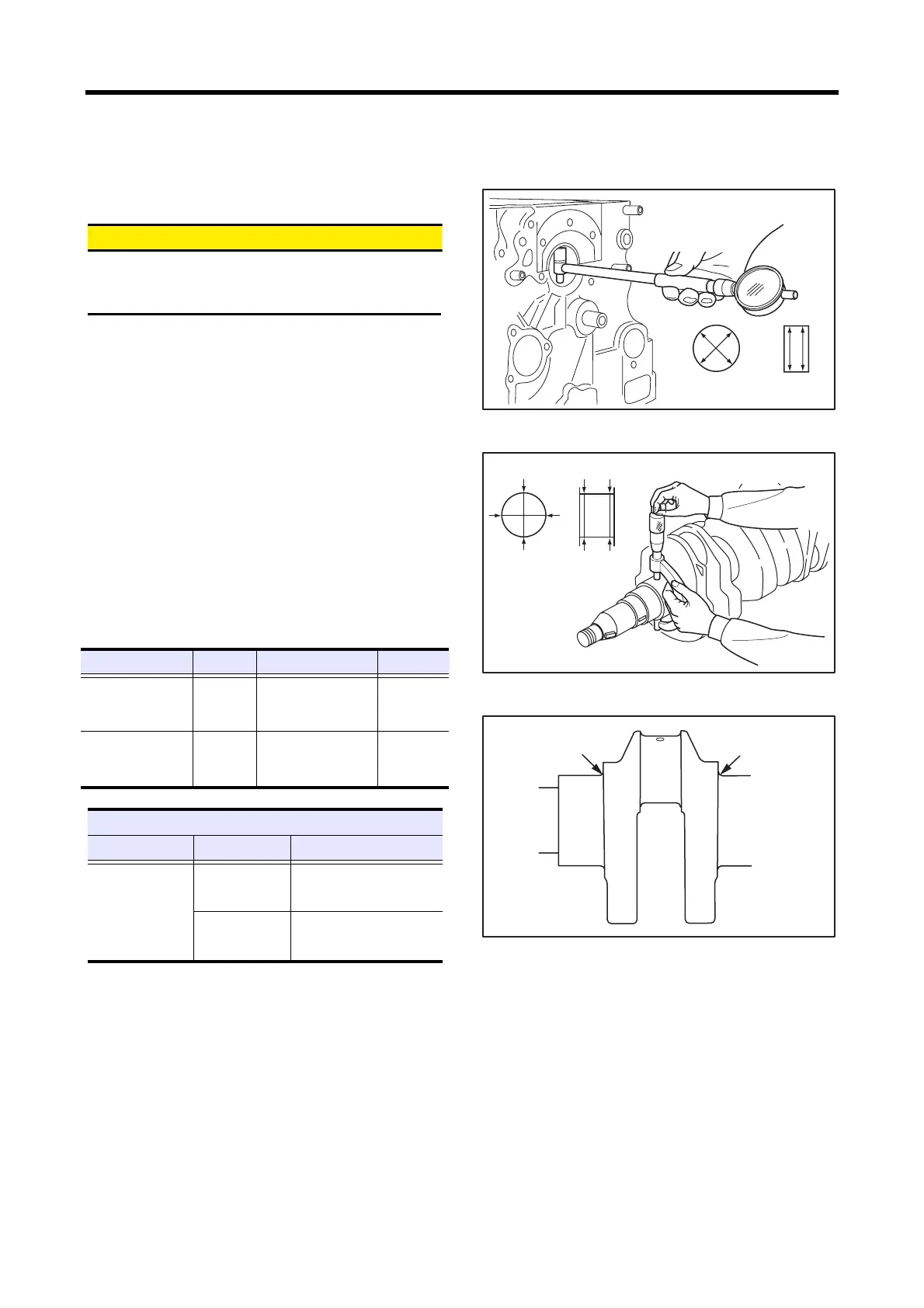

(4) Measure the outside diameter of the crank journal.

(5) Calculate the clearance between the inside diameter of

the main bearing and outside diameter of the crank

journal.

(6) Replace the main bearing if the clearance exceeds the

limit.

(7) Measure the clearance between the main bearing cap

and the crank journal again. Use the undersize bearing

if the limit is exceeded.

(8) If an undersize bearing is used, grind the crank journal

to the specified undersize.

Measuring main bearing fitting bore

Measuring crank journal outside diameter

Finish dimension of fillet radius

Item Nominal Standard Limit

Outside diameter of

crankshaft journal

(STD)

ø 43 mm

[1.69 in.]

42.965 to 42.980 mm

[1.6915 to 1.6921 in.]

–

Clearance between

main bearing and

crankshaft journal

–

0.030 to 0.075 mm

[0.0012 to 0.0030 in.]

0.10 mm

[0.0039 in.]

Undersize grinding dimensions of crankshaft

Item Undersize Finish dimension

Crank journal

undersize

0.25 mm

[0.0098 in.]

ø 42.75 -0.035

-0.020

mm

[1.6831

-0.0014

-0.0008

in.]

0.50 mm

[0.0197 in.]

ø 42.50

-0.035

-0.020

mm

[1.6732

-0.0014

-0.0008

in.]

Measuring

directions

Measuring

points

Tightening torque

49.0 to 53.9 N㨯m

{5.0 to 5.5 kgf㨯m}

[36.2 to 39.8 lbf㨯ft]

Measuring

directions

Measuring

points

R2

0

-0.2

mm

[0.08

0

-0.008

in.]

R2

0

-0.2

mm

[0.08

0

-0.008

in.]

Loading...

Loading...