INSPECTION AND REPAIR OF BASIC ENGINE

6-12

4.2 Reboring cylinder

Cylinders shall be rebored according to the following

procedure.

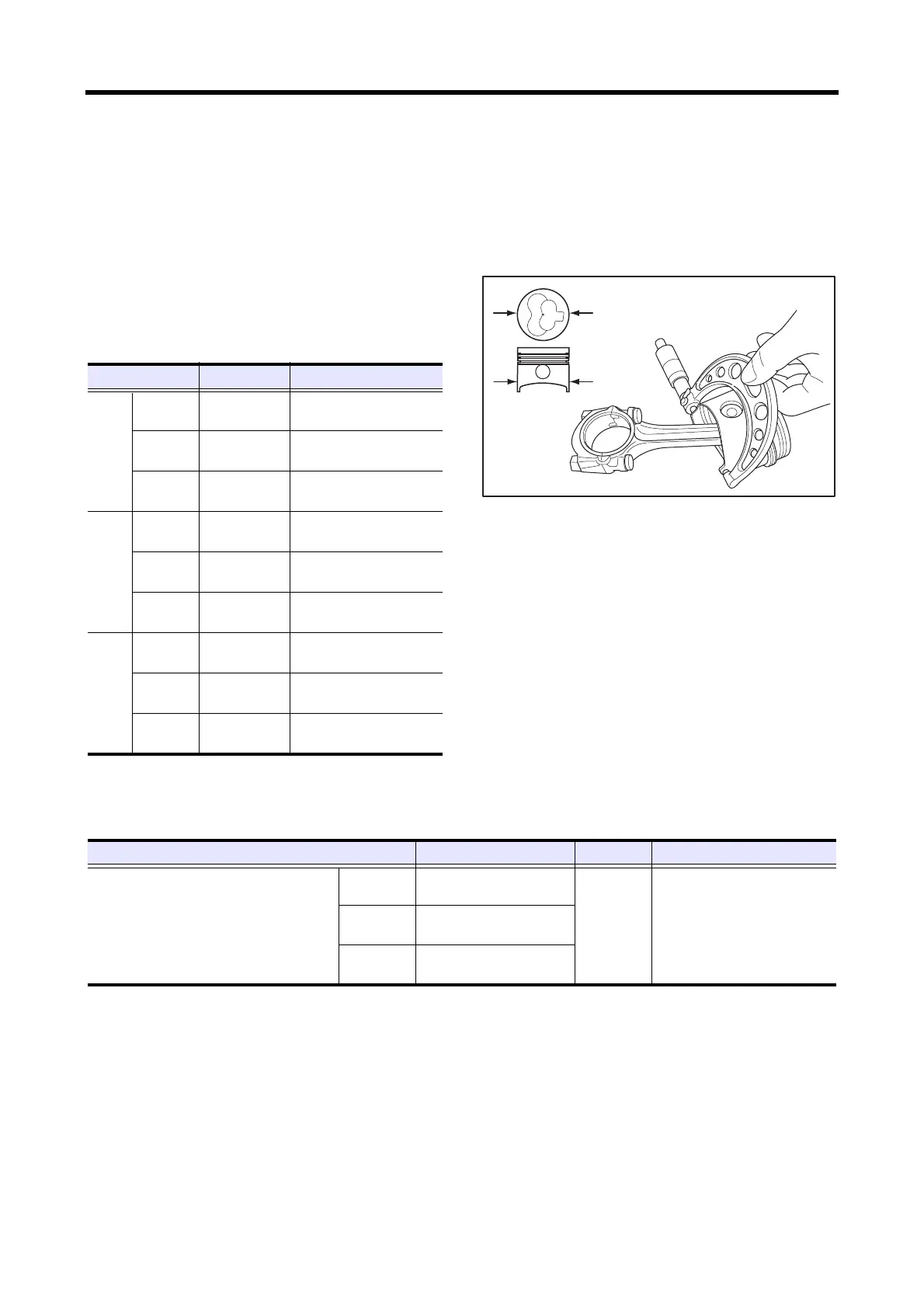

4.2.1 Measuring piston outside diameter

Using a micrometer, measure the piston outside diameter at

the skirt perpendicular to the piston pins as shown in the

illustration.

Measuring piston outside diameter

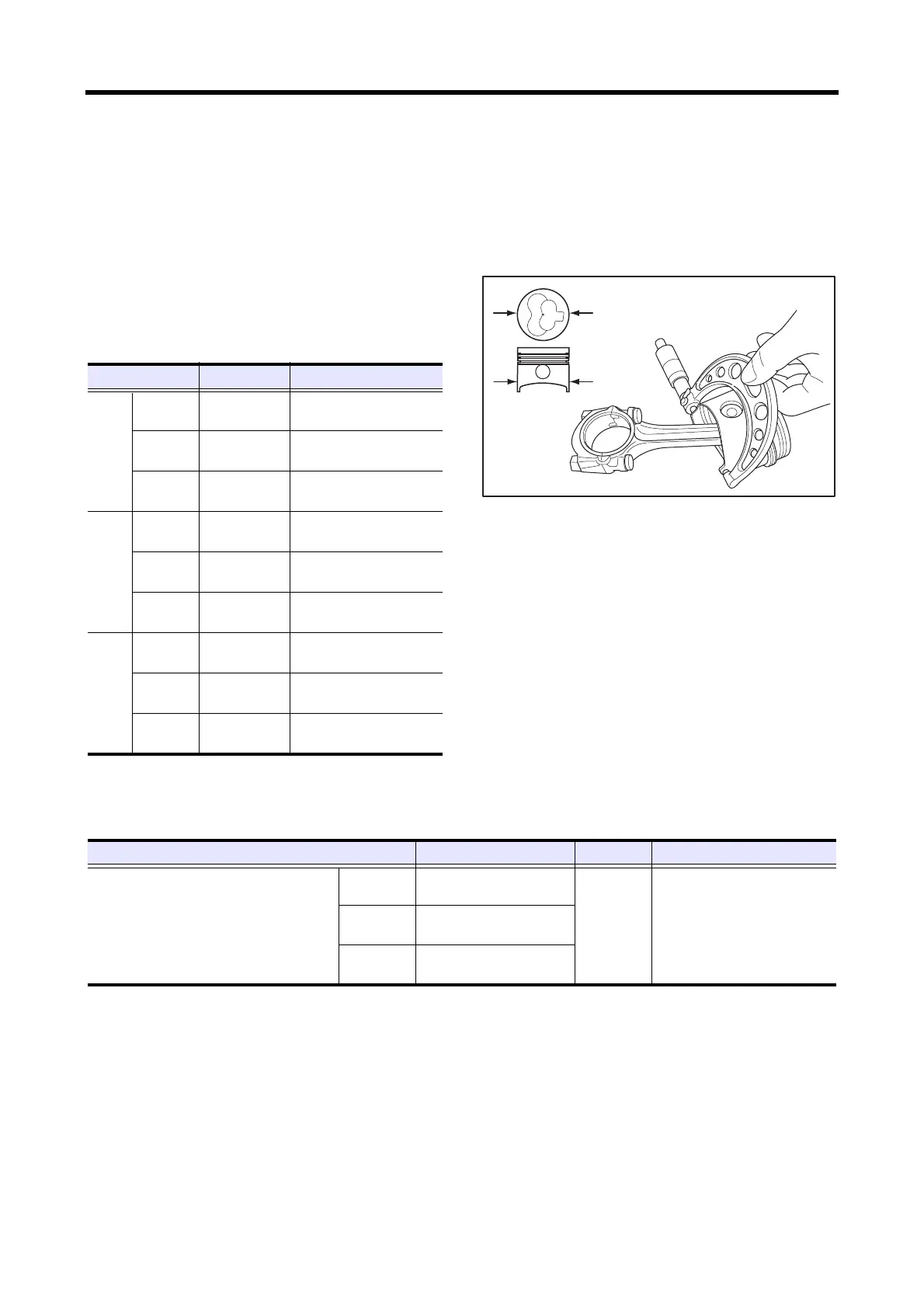

4.2.2 Boring finish dimension

= [piston diameter] + [clearance] - [honing allowance (0.02 mm [0.0008 in.])]

Item Nominal Standard

L2A

L3A

STD

ø 65 mm

[2.559 in.]

64.919 to 64.939 mm

[2.5559 to 2.5566 in.]

0.25 OS

ø 65.25 mm

[2.569 in.]

65.169 to 65.189 mm

[2.5657 to 2.5665 in.]

0.50 OS

ø 65.50 mm

[2.579 in.]

65.419 to 65.439 mm

[2.5755 to 2.5763 in.]

L2C

L3C

STD

ø 70 mm

[2.756 in.]

69.913 to 69.933 mm

[2.7525 to 2.7533 in.]

0.25 OS

ø 70.25 mm

[2.766 in.]

70.163 to 70.183 mm

[2.7623 to 2.7631 in.]

0.50 OS

ø 70.50 mm

[2.776 in.]

70.413 to 70.433 mm

[2.7722 to 2.7729 in.]

L2E

L3E

STD

ø 76 mm

[2.992 in.]

75.906 to 75.926 mm

[2.9884 to 2.9892 in.]

0.25 OS

ø 76.25 mm

[3.002 in.]

75.156 to 76.176 mm

[2.9983 to 2.9990 in.]

0.50 OS

ø 76.50 mm

[3.012 in.]

76.406 to 76.426 mm

[3.0081 to 3.0089 in.]

Measuring

positions

Direction at right

angles to piston pin

Item Standard Limit Remark

Clearance

(clearance between piston and cylinder)

L2A, L3A

0.061 to 0.111 mm

[0.0024 to 0.0044 in.]

0.2 mm

[0.0079 in.]

Repair to oversize or replaceL2C, L3C

0.067 to 0.117 mm

[0.0026 to 0.0046 in.]

L2E, L3E

0.074 to 0.124 mm

[0.0029 to 0.0049 in.]

Loading...

Loading...