FUEL SYSTEM

8-12

2.3 Inspecting fuel injection pump on engine

Do not disassemble the fuel injection pump unless it is absolutely necessary.

If faulty, it is desirable to replace it as an assembly.

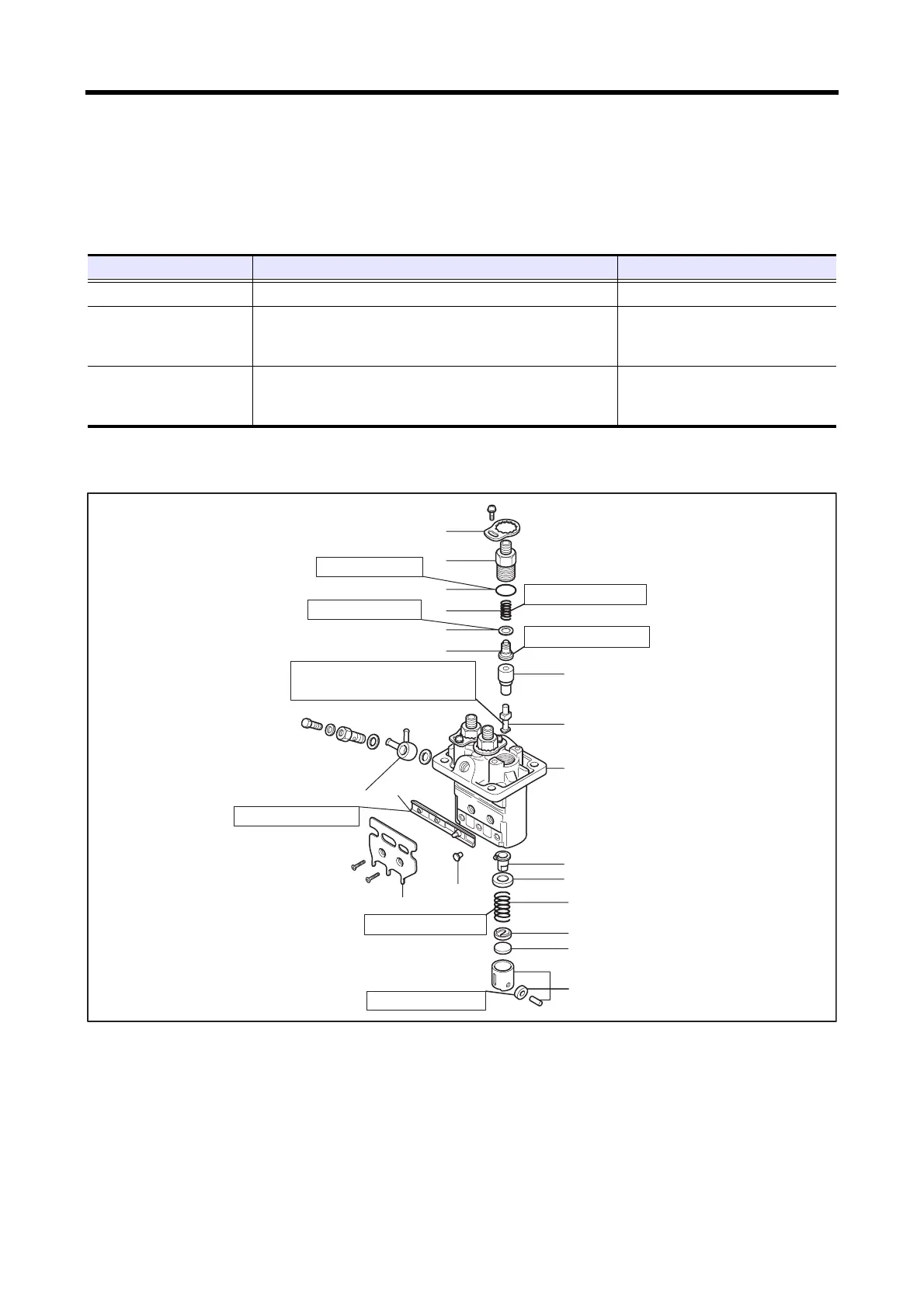

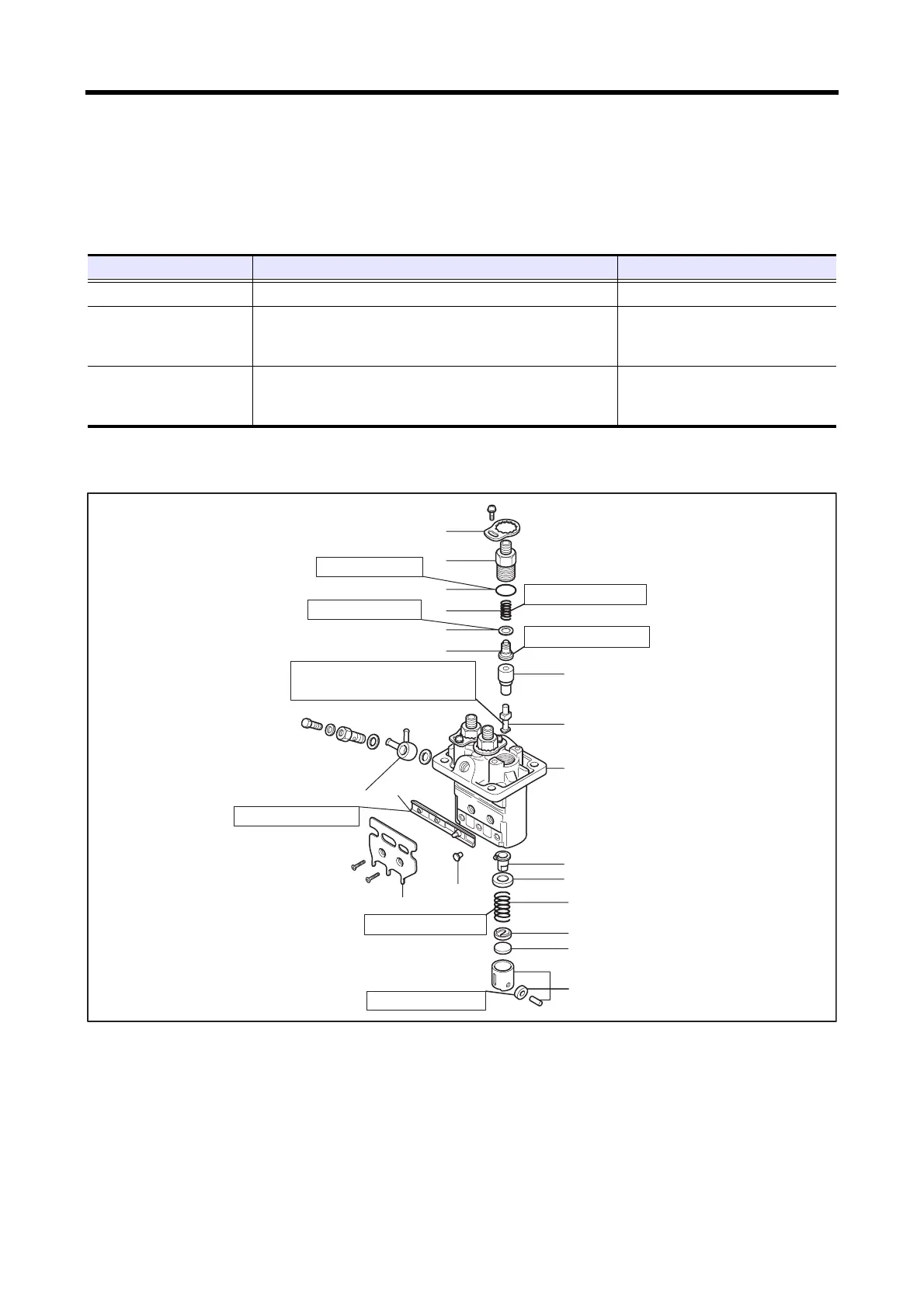

2.4 Disassembling and inspecting fuel injection pump

Disassembling and inspecting fuel injection pump

Disassembing sequence

Inspection item Inspection procedure Judgment

Low idling Judgment by rotation speed (Varies depending on specifica tion)

Exhaust color

Observe exhaust color during sudden acceleration under

no load.

Observe exhaust color under load.

No remarkable black smooke is

emitted.

Nozzle injection condition

Remove the nozzle and reassemble them so that spray holes

face outward. Rotate the starter to carefully observe the spray

pattern.

The spray pattem must be good.

1 Swivel nipple 8 Plunger 15 Delivery valve spring

2 Stop wire bracket 9 Plunger spring 16 Delivery valve gasket

3 Control rack 10 Spring upper seat 17 Delivery valve

4 Tappet guide pin 11 Control sleeve 18 Plunger barrel

5 Tappet 12 Lock plates 19 Pump housing

6 Tappet shim plate 13 Delivery valve holder

7 Spring lower seat 14 O-rings

Fatigue and crack

Wear and damage

Contact, wear, damage,

rust and seizure of plunger

Replace: O-ring

Replace: Gasket

Fatigue and crack

Contact and wear

Operating condition

Loading...

Loading...