ELECTRICAL SYSTEM

12-23

2.6 Inspection before disassembling starter (M002T66071 (24V-3.2kW))

2.6.1 Inspecting pinion clearance

&$87,21

Do not apply current continuously for longer than 10

seconds.

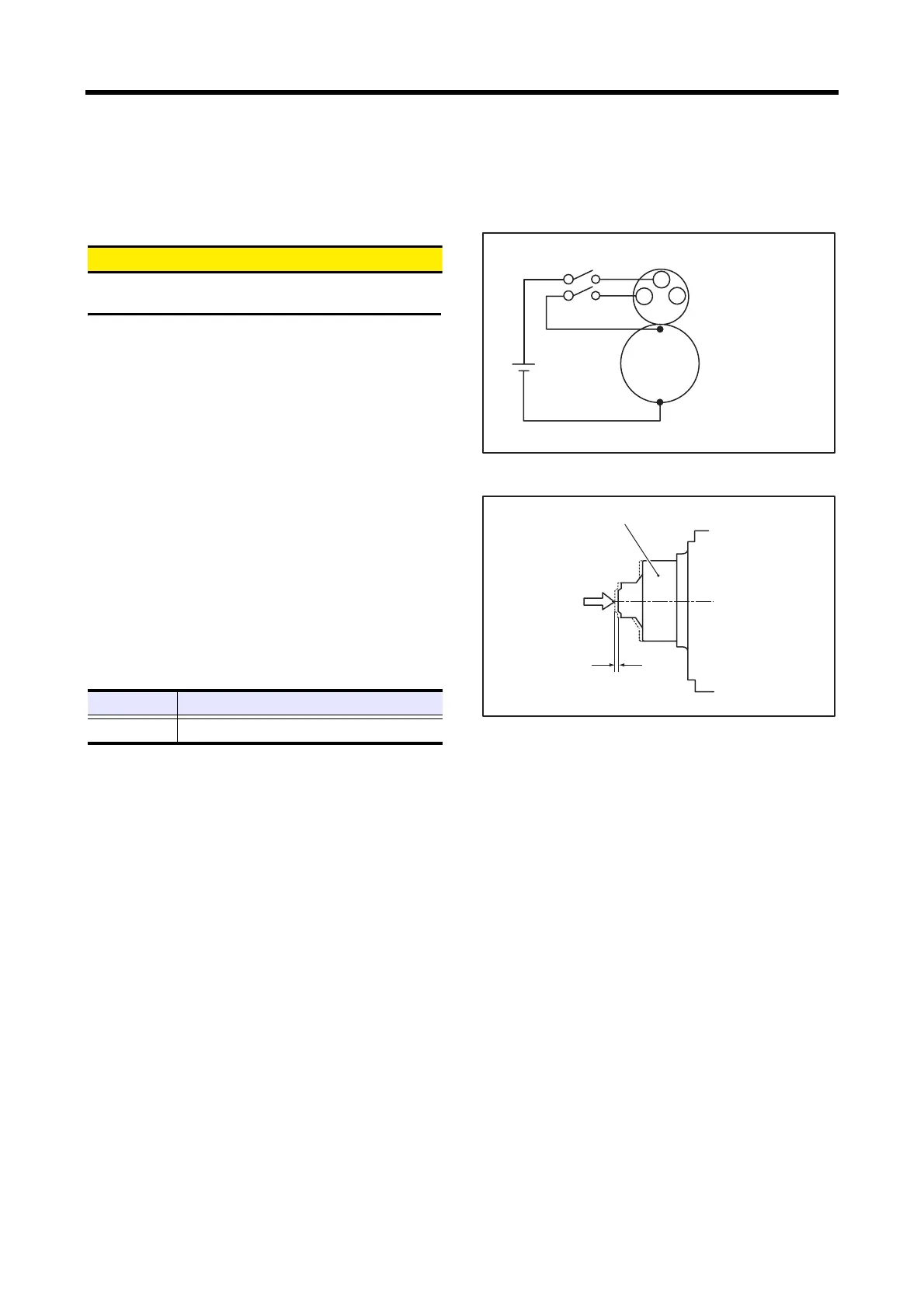

(1) Connect the starter to the circuit as shown in the

illustration.

(2) When the switches SW1 and SW2 are turned ON, the

pinion springs out to the cranking position and the

armature rotates.

(3) Turn the switch SW2 OFF to stop the rotation of the

armature.

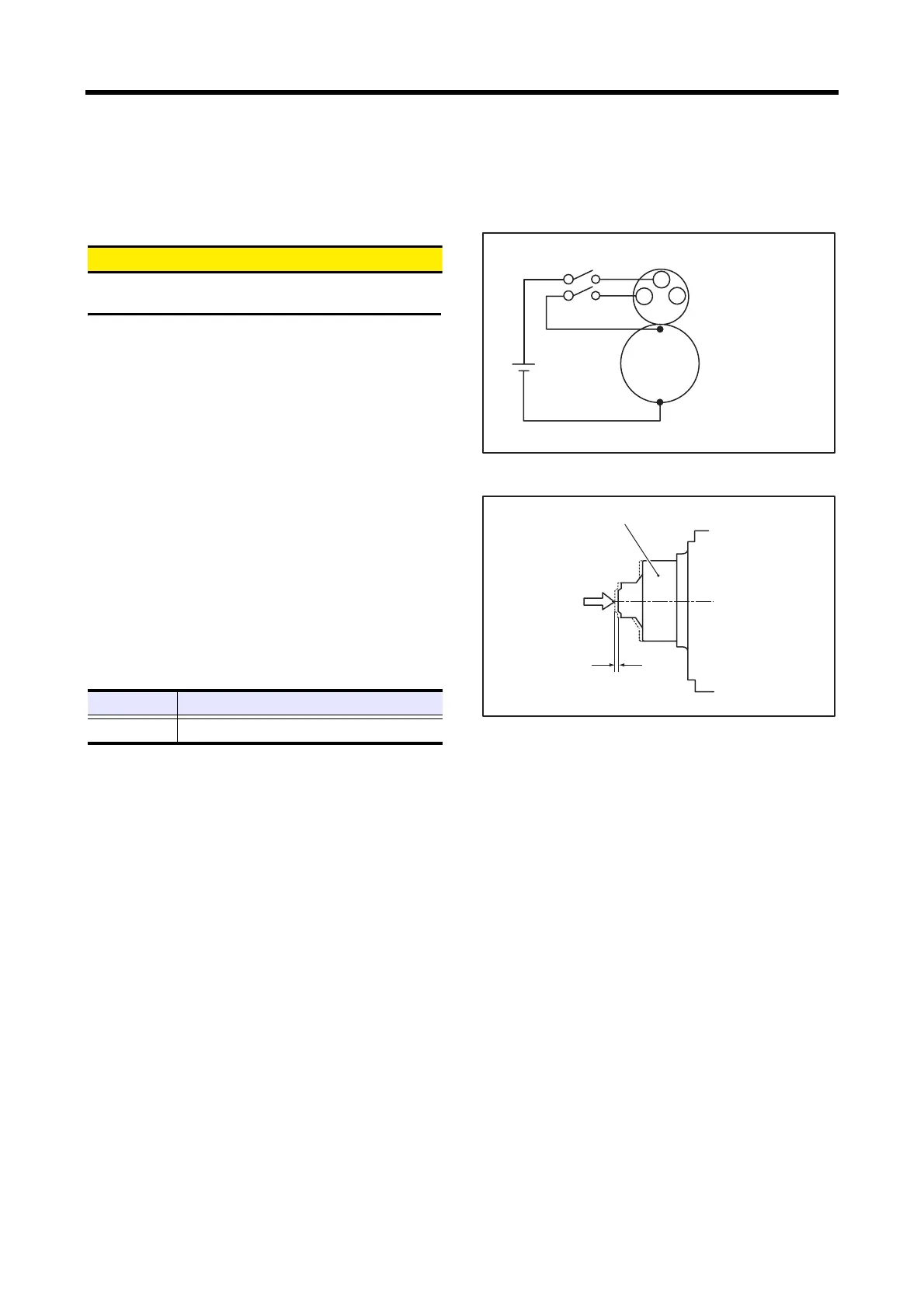

(4) Gently push back the pinion in the out position with a

finger and measure the distance over which the pinion

has returned (movement amount).

(5) If the measured value is out of the standard, increase or

decrease the number of packings between the magnetic

switch and the front bracket for adjustment, or replace

the lever with a new one.

Note: When the number of packings is increased, the pinion

clearance becomes small.

Wiring during inspection of pinion clearance

Inspecting pinion clearance

Item Standard

Pinion gap 0.5 to 2.0 mm [0.0197 to 0.0787 in.]

59

59

Battery

24V

㧮

㧿

㧹

Disconnect the lead

with a terminal

connected to

terminal M.

Pinion

Gently push back

the pinion.

Pinion clearance

0.5 to 2.0 mm [0.0197 to 0.0787 in.]

Loading...

Loading...