INSPECTION AND REPAIR OF BASIC ENGINE

6-15

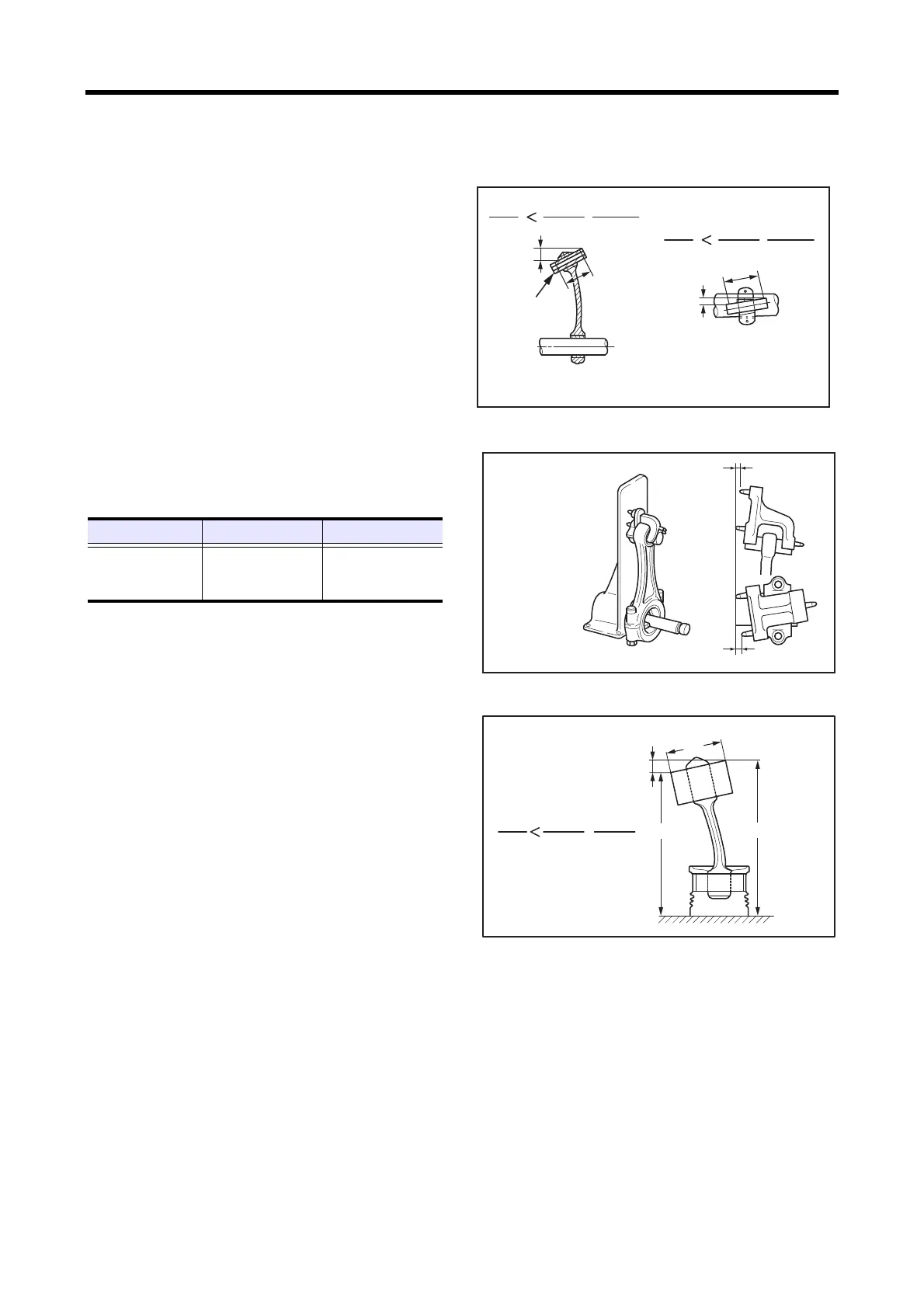

4.7 Inspecting connecting rod bend and twist

(1)

Measure the dimensions of C and L in the illustration to

check bend and twist of the connecting rod. Straighten

the connecting rod with a press to meet the standard.

If the standard is exceeded after correction, replace the

connecting rod with a new one.

(2) In general, a connecting rod aligner is used to check

bend and twist.

Note: Before checking bend, tighten the connecting rod cap

to the specified torque.

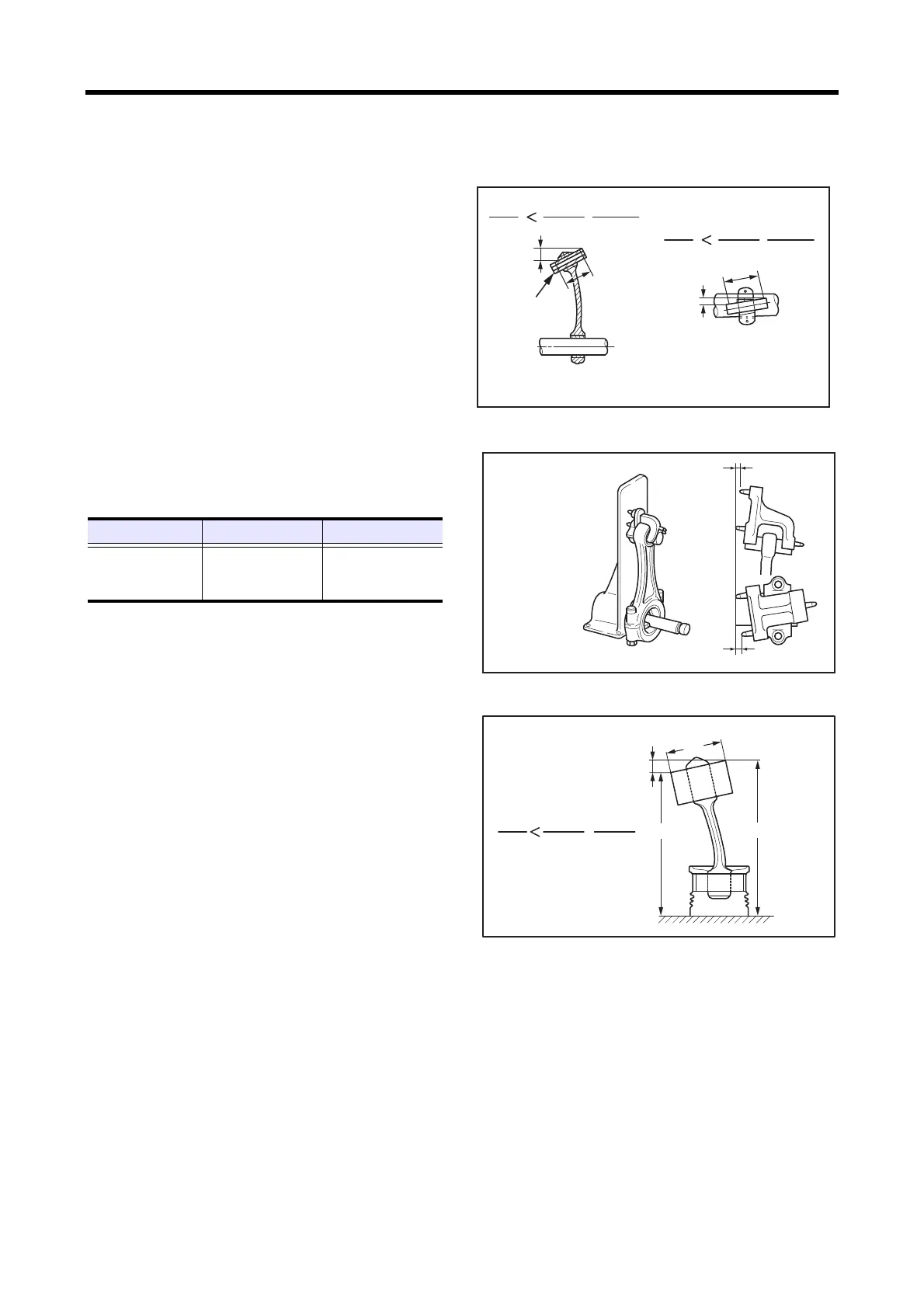

(3) To inspect the connecting rod with the piston installed,

turn the piston upside down and place it on a surface

plate. Insert a round bar having the same diameter as

the crankpin into the big-end bore, and measure the

height of the bar using a dial gauge.

Inspecting connecting rod bend and twist

Measurement with connecting rod aligner

Measuring bend of connecting rod

Item Standard Limit

Bend and twist of

connecting rod

0.05/100 mm

[0.0020/3.94 in.]

or less

0.15/100 mm

[0.0059/3.94 in.]

C

C

L

L

Piston

pin

Connecting rod bend

Connecting rod twist

Unit: mm [in.]

C

100 3.94

0.05 0.0020

L

[]

C

100 3.94

0.05 0.0020

L

[]

Tightening torque

of connecting rod

cap

31.4 to 34.3 N㨯m

{3.2 to 3.5 kgf㨯m}

[23.1 to 25.3 lbf㨯ft]

C

A

B

D

Unit: mm [in.]

D

C

100

0.05

3.94

0.0020

[ ]

Loading...

Loading...