INSPECTION AND REPAIR OF BASIC ENGINE

6-11

4. Inspecting and repairing cylinder block, crankshaft, piston and oil pan

4.1 Measuring cylinder inside diameter

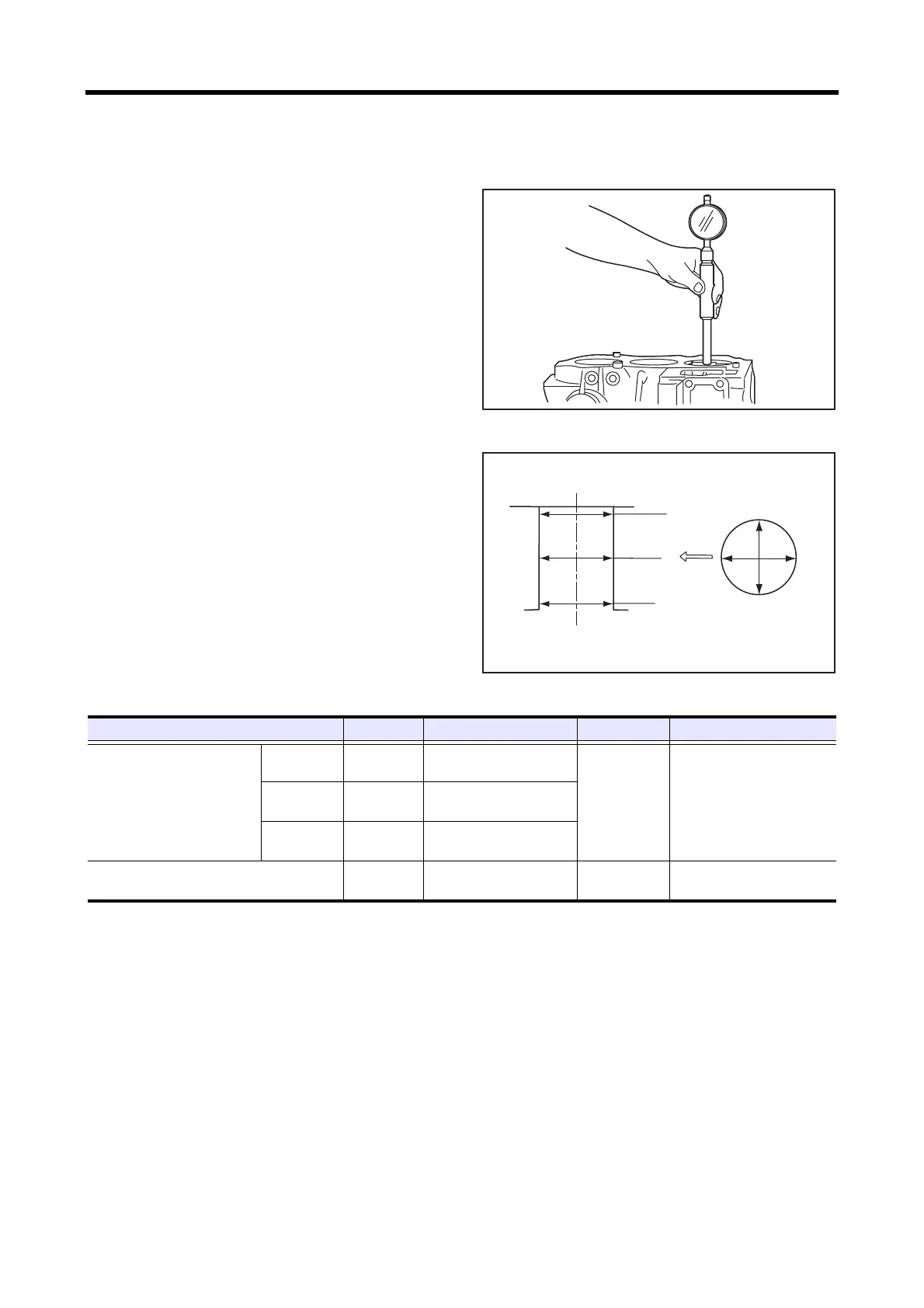

Use a cylinder gauge to measure the inside diameter and

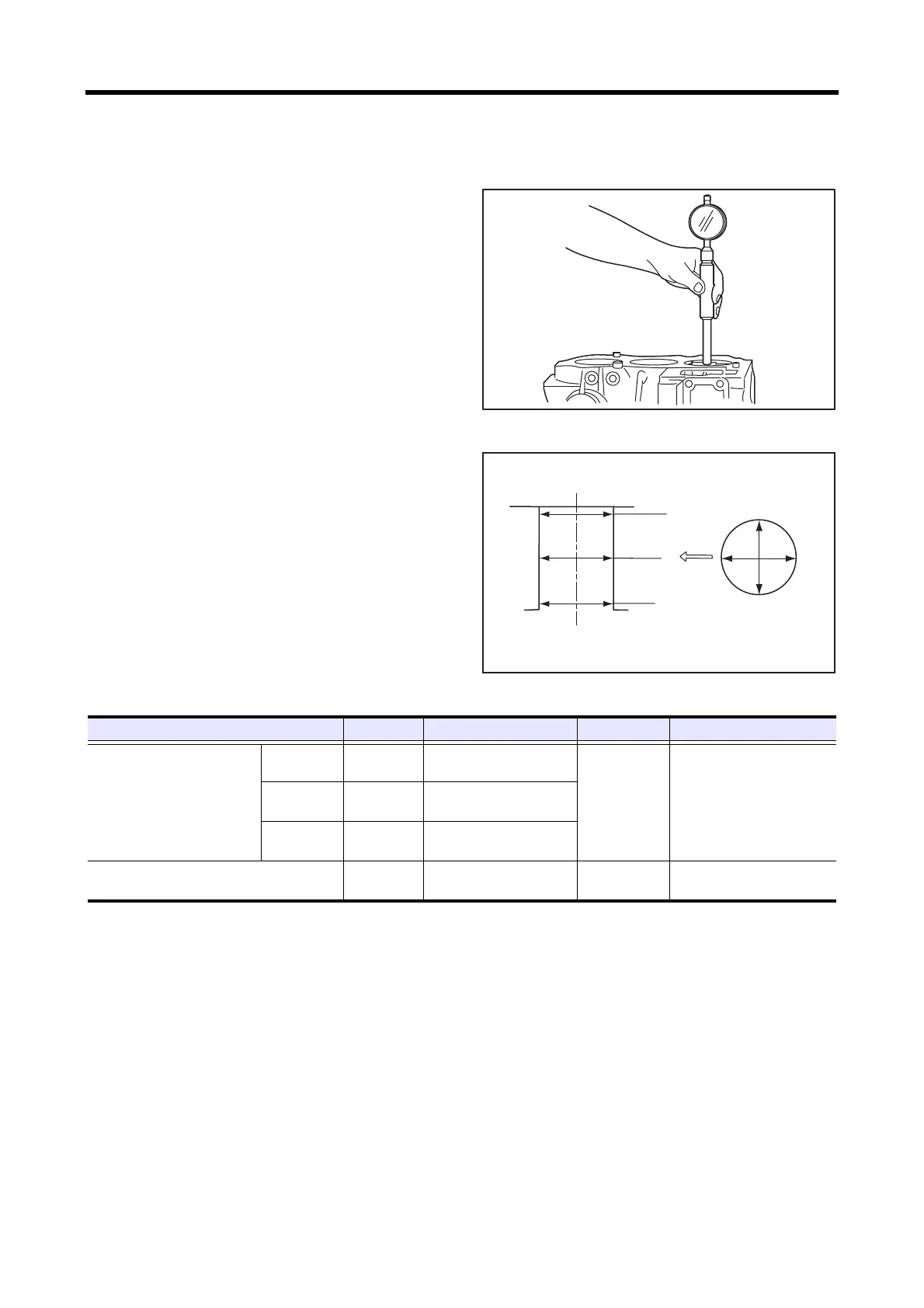

cylindericity of the cylinder at three locations in the A and B

directions as shown in the illustration.

If any one of the cylinders exceeds the repair limit, bore all

the cylinders and replace the pistons and piston rings with

oversize ones.

Replace the cylinder block if the limit is exceeded.

Measuring cylinder inside diameter

Measuring position of cylinder inside diameter

㧭

㧮

Approx. 10 mm [0.39 in.]

from top end

Center

Front

Bottom

Measuring

positions

Measuring

directions

Item Nominal Standard Limit Remark

Cylinder inside diameter

L2A, L3A

ø 65 mm

[2.56 in.]

65.00 to 65.03

[2.5591 to 2.5602 in.]

+0.7 mm

[+0.0276 in.]

Repair limit is +0.2 mm

[+0.0079 in.]

L2C, L3C

ø 70 mm

[2.76 in.]

70.00 to 70.03

[2.7559 to 2.7571 in.]

L2E, L3E

ø 76 mm

[2.99 in.]

76.00 to 76.03

[2.9921 to 2.9933 in.]

Cylindericity of cylinder -

0.01 mm

[0.0004 in.] or less

--

Loading...

Loading...