DISASSEMBLY OF BASIC ENGINE

5-7

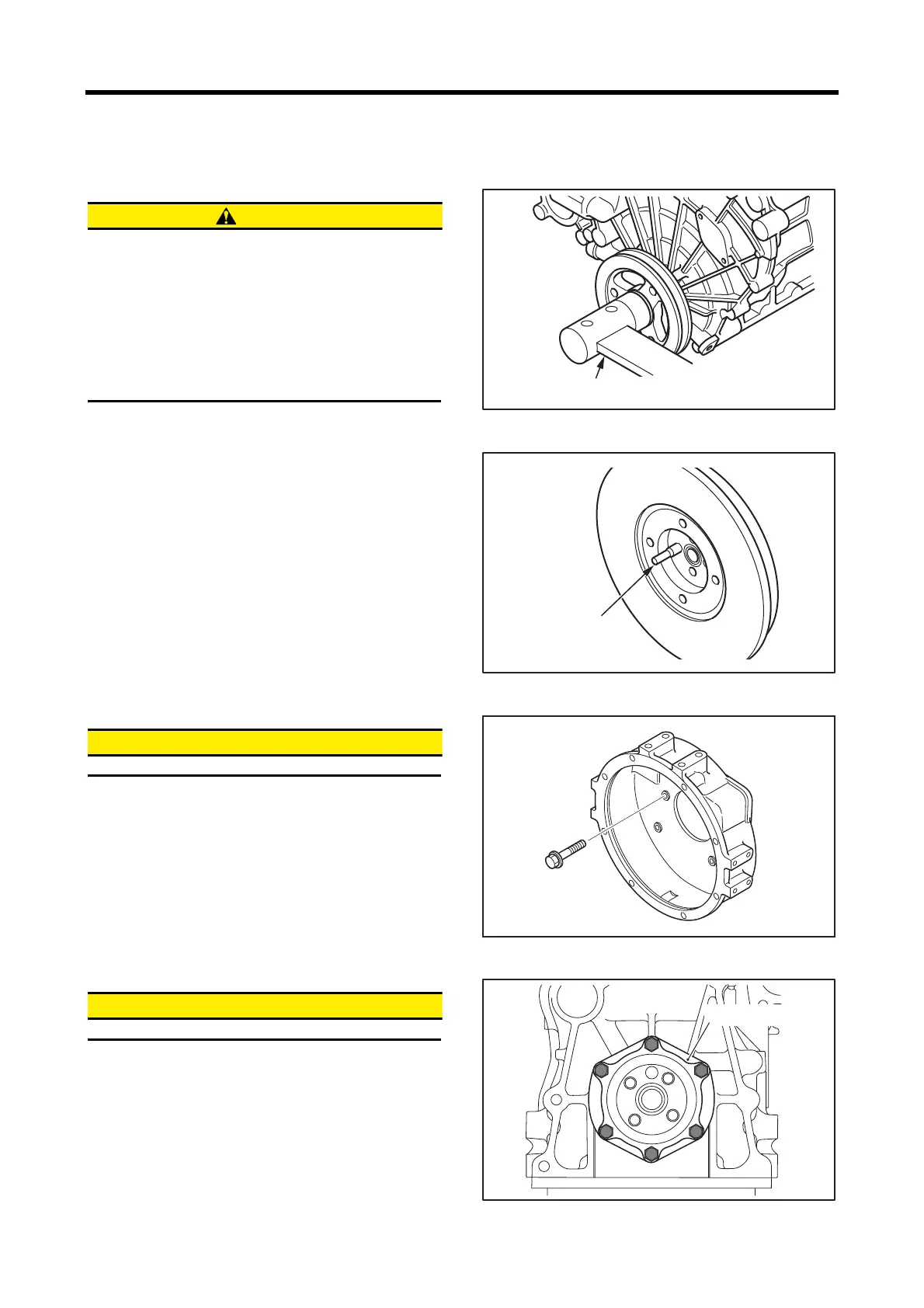

2.1 Removing flywheel

&$87,21

(a) Be careful not to cut yourself with the ring gear

when pulling out the flywheel.

Be careful not to drop or hit the flywheel when

removing.

(b) The personnel who holds the pulley must pay due

attention to safety.

Also, personnel must stay in close contact with

each other during work.

(1) One personnel must firmly hold the pulley with a

wrench to prevent the flywheel from turning.

(2) Remove one bolt from the flywheel.

(3) Screw a guide bolt into the threaded hole of the bolt that

has been removed.

(4) Remove remaining bolts from the flywheel.

(5) Hold the flywheel firmly with both hands, and by

moving it back and forth, pull it out straight.

Note: The ring gear is shrink fitted to the flywheel. Do not

remove the ring gear unless it is defective.

Detent of flywheel

Removing flywheel

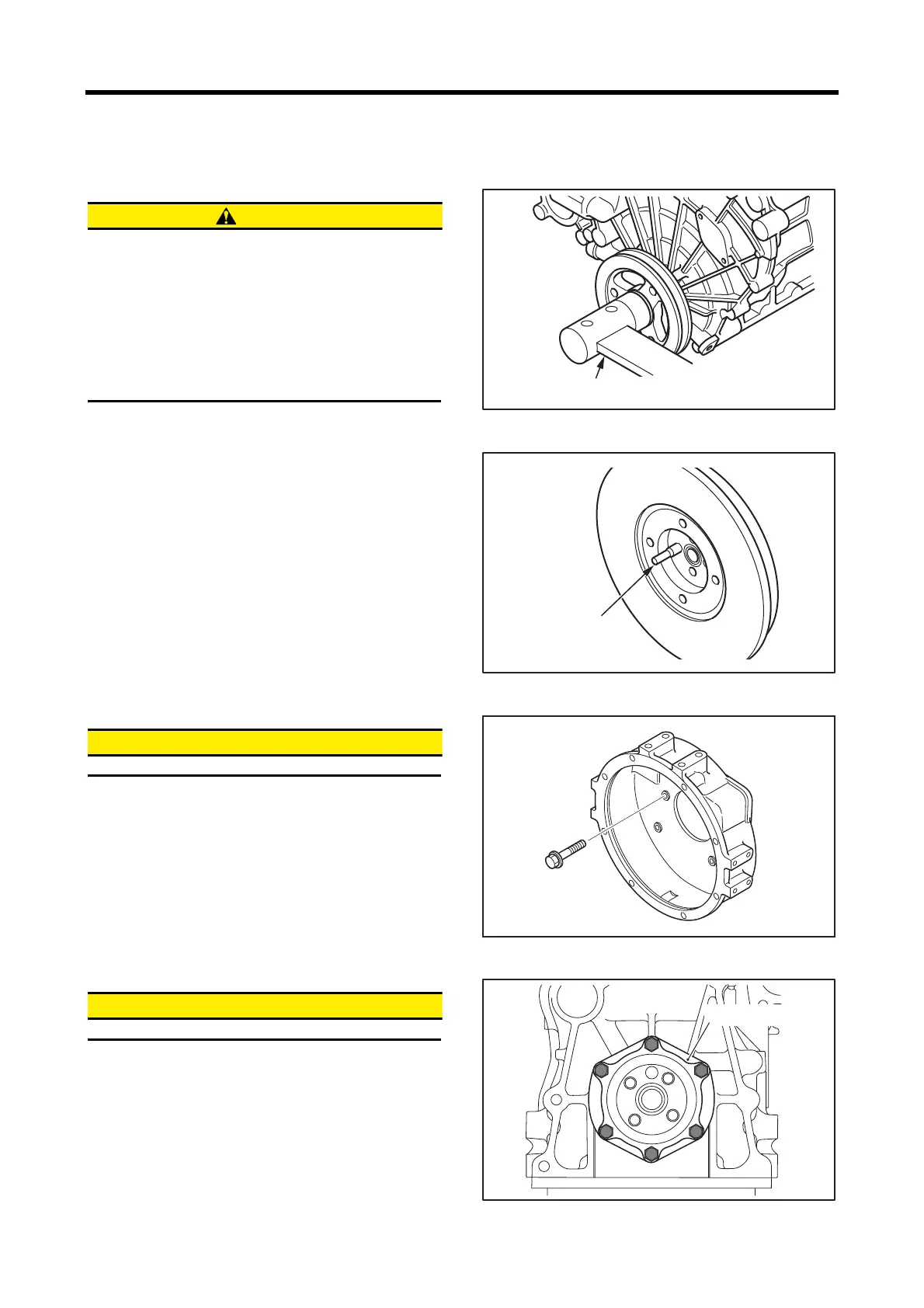

2.2 Removing flywheel housing

&$87,21

Be careful not to damage the oil seal.

(1) Remove bolts from the flywheel housing.

(2) Remove the flywheel housing.

Removing flywheel housing

2.3 Removing oil seal case

&$87,21

Be very careful not to damage the oil seal.

(1) Remove bolts from the oil seal case.

(2) Pry out the oil seal case from the cylinder block using a

screwdriver.

Removing oil seal case

Prevent the flywheel from rotating

using a wrench.

Guide bolt

(M101.25mm)

Oil seal case

Loading...

Loading...