INSPECTION AND REPAIR OF BASIC ENGINE

6-7

2. Inspecting and repairing flywheel

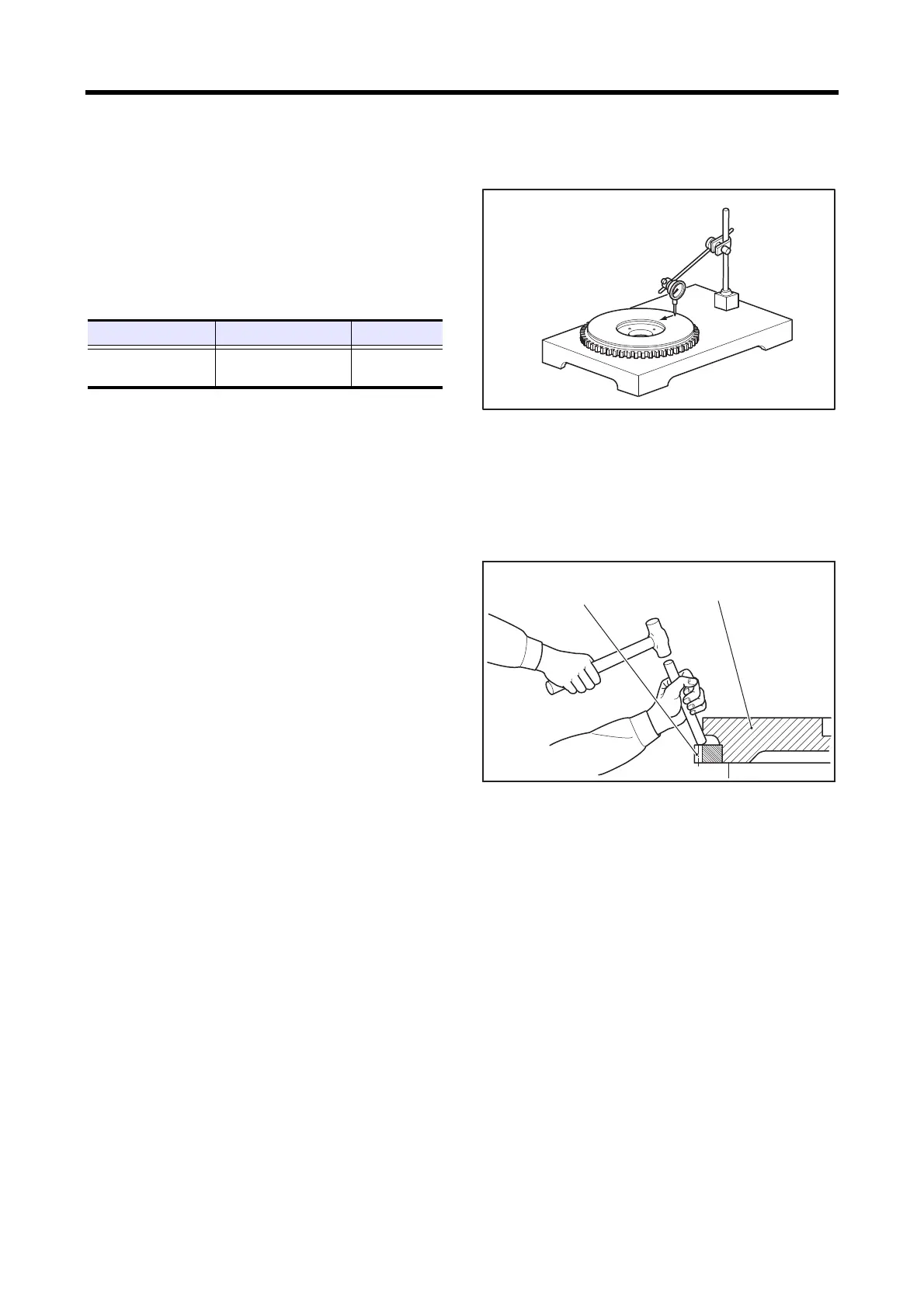

2.1 Measuring flatness of flywheel

Place the flywheel on a surface plate and move a dial gauge

on the friction surface of the flywheel to measure the

flatness.

Grind the friction surface of the flywheel if the limit is

exceeded.

Measuring flatness of flywheel

2.2 Inspecting ring gear

Inspect the ring gear for a missing tooth or worn teeth, and

if defects are found, replace the ring gear.

2.3 Replacing ring gear

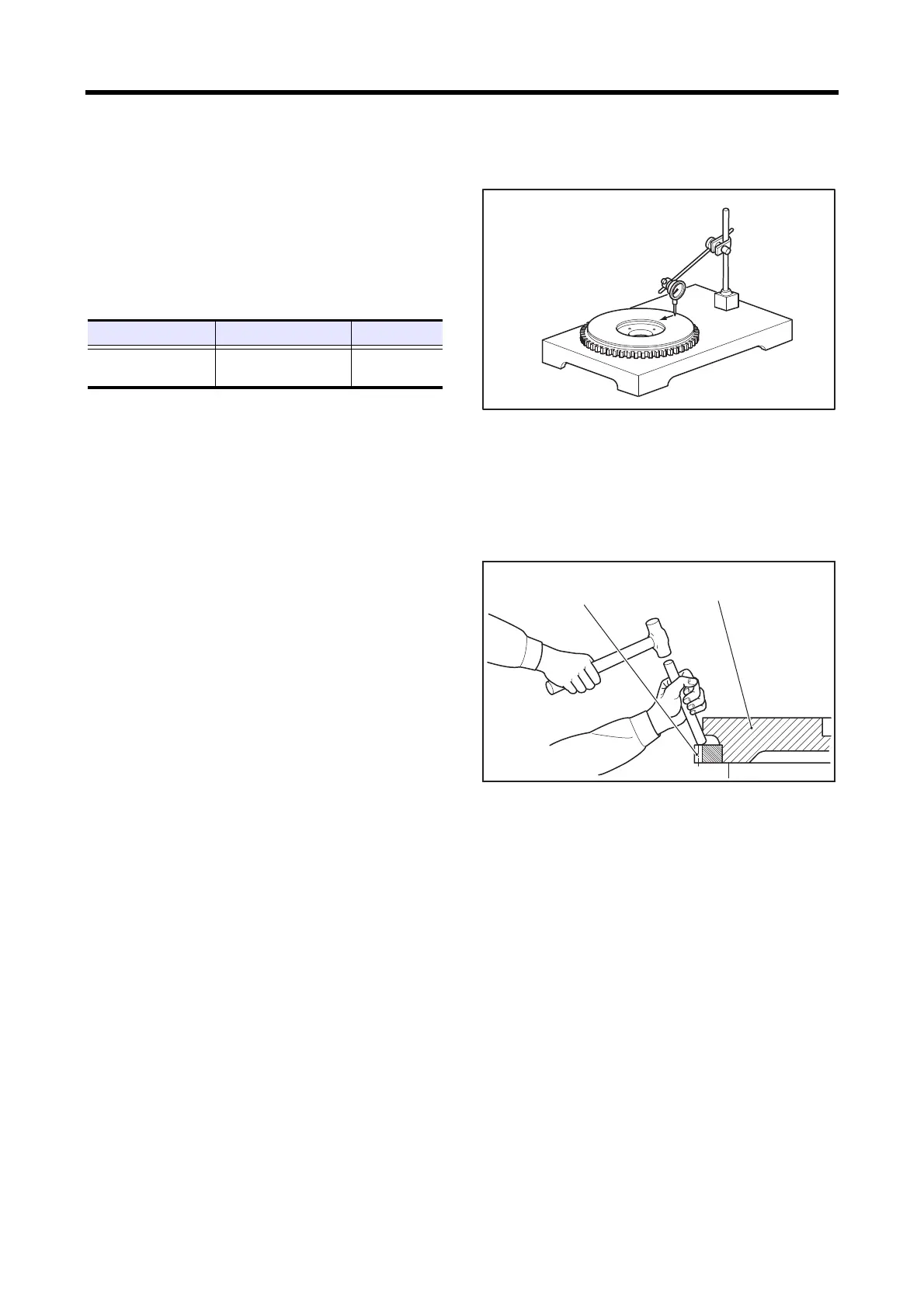

2.3.1 Removing ring gear

(1) Heat the ring gear evenly with an acetylene torch or

other appropriate heat source.

(2) Remove the ring gear by striking it evenly around the

periphery with a hammer through a rod.

2.3.2 Installing ring gear

(1) Heat the ring gear evenly up to approx. 100°C [212°F]

with an appropriate heater.

(2) Install the ring gear onto the flywheel with the no-gear-

chamfering side facing to the flywheel.

Note: Do not heat the ring gear excessively.

Removing ring gear

Item Standard Limit

Flywheel flatness

0.08 mm

[0.0031 in.] or less

0.50 mm

[0.0197 in.]

Flywheel

Ring gear

Loading...

Loading...