INSPECTION AND REPAIR OF BASIC ENGINE

6-5

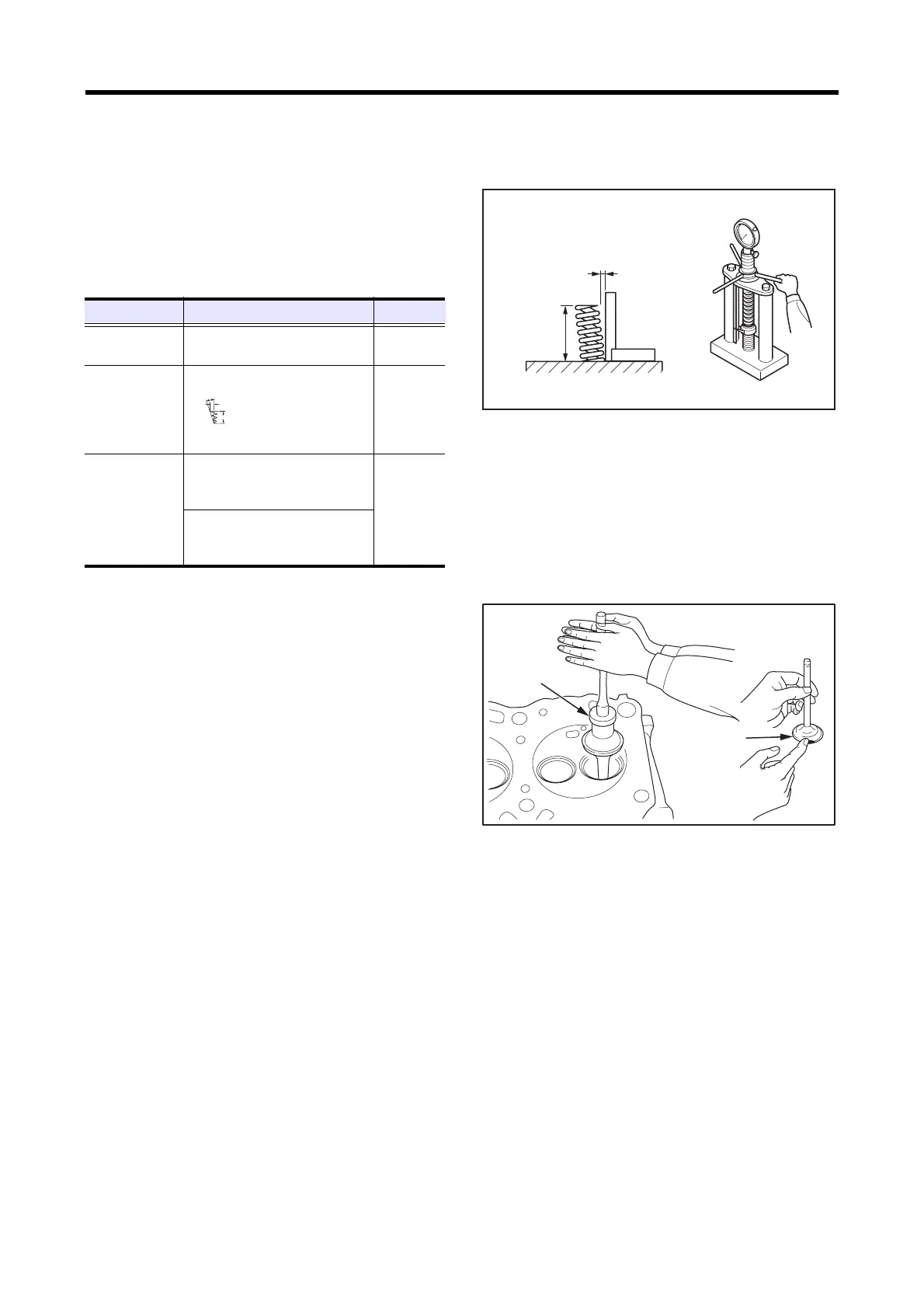

1.6 Measuring perpendicularity and free length

of valve spring

Measure the perpendicularity and free length of the valve

spring. If the limit is exceeded, replace the valve spring with

a new one.

Squareness and free length of spring

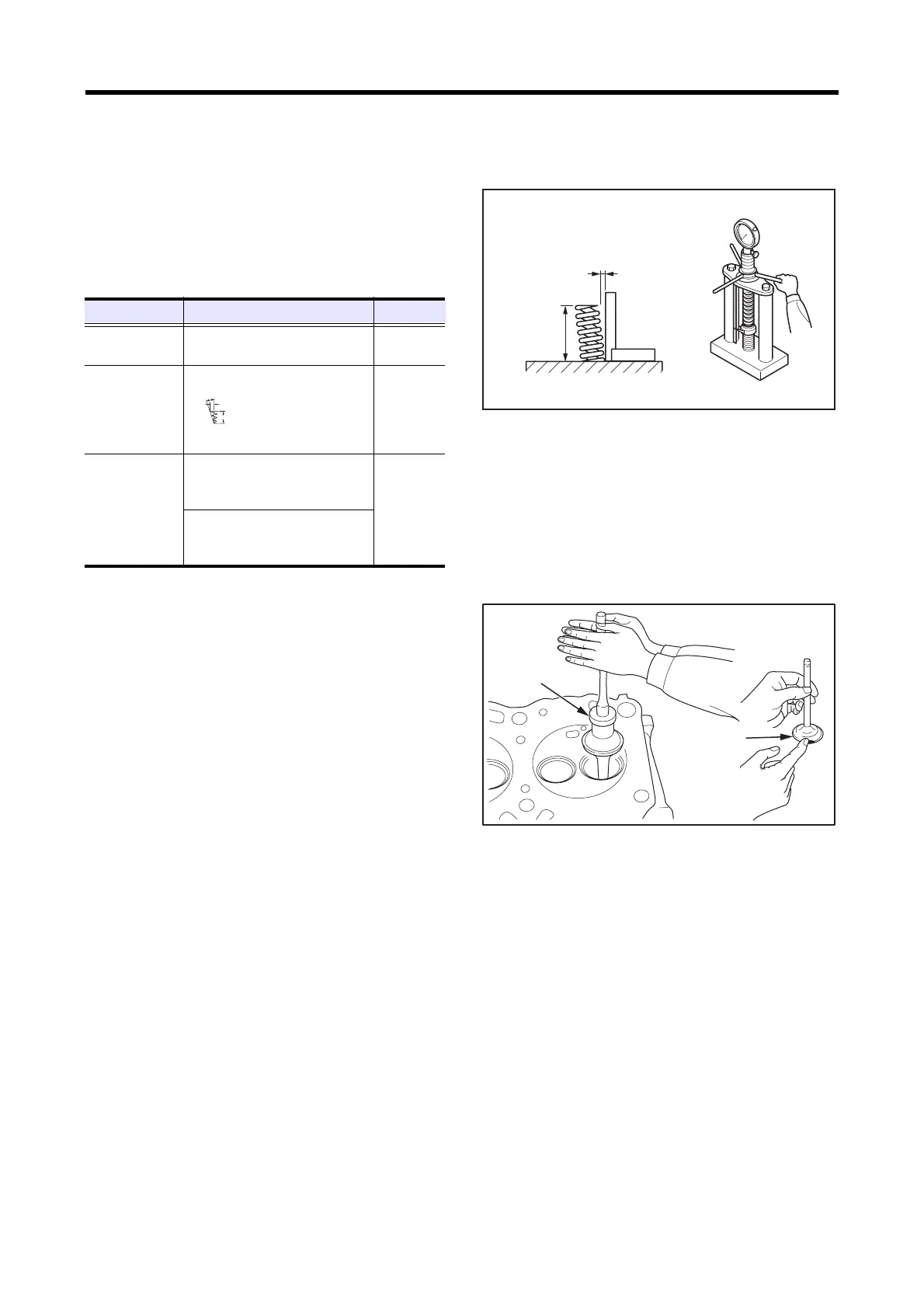

1.7 Lapping valve and valve seat

Always lap the valve against the valve seat after refacing the

valve seat or after replacing the valve.

(1) Apply a thin coat of lapping compound evenly to the

valve face.

Note: (a) Do not allow the compound to adhere on the

valve stem.

(b) Compound spreads more evenly if it is mixed

with a small amount of engine oil.

(c) Use medium-grain compound (120 to 150 mesh)

for initial lapping, then use fine-grain compound

(200 mesh or finer) for finishing.

(2) Use a valve lapper for lapping. Strike the valve against

the valve seat while rotating the valve little by little.

(3) Wash off the compound using diesel fuel.

(4) Coat the contact surface of the valve with engine oil,

then lap the valve again.

(5) Check valve-to-seat contact.

Lapping valve and valve seat

Item Standard Limit

Free length

40 mm

[1.57 in.]

38.5 mm

[1.516 in.]

Perpendicularity

θ = 2.0 °or less

Δ (gap) = 1.4 mm

[0.055 in.] or less

Lf = 40 mm [1.57 in.]

△ = 2.0

mm

[0.079 in.]

over entire

length

Set length/set

force

35.5 [1.3976] / 55.3 to 61.2 N

{5.64 to 6.24 kgf}

[12.4 to 13.8 lbf]

-15 %

28.0 [1.1024] / 138.2 to 152.9 N

{14.09 to 15.59 kgf}

[31.1 to 34.4 lbf]

ٌ

Lf

ǰ

Free length

Spring perpendicularity (gap)

Valve lapper

Compound

Loading...

Loading...