DISASSEMBLY OF BASIC ENGINE

5-15

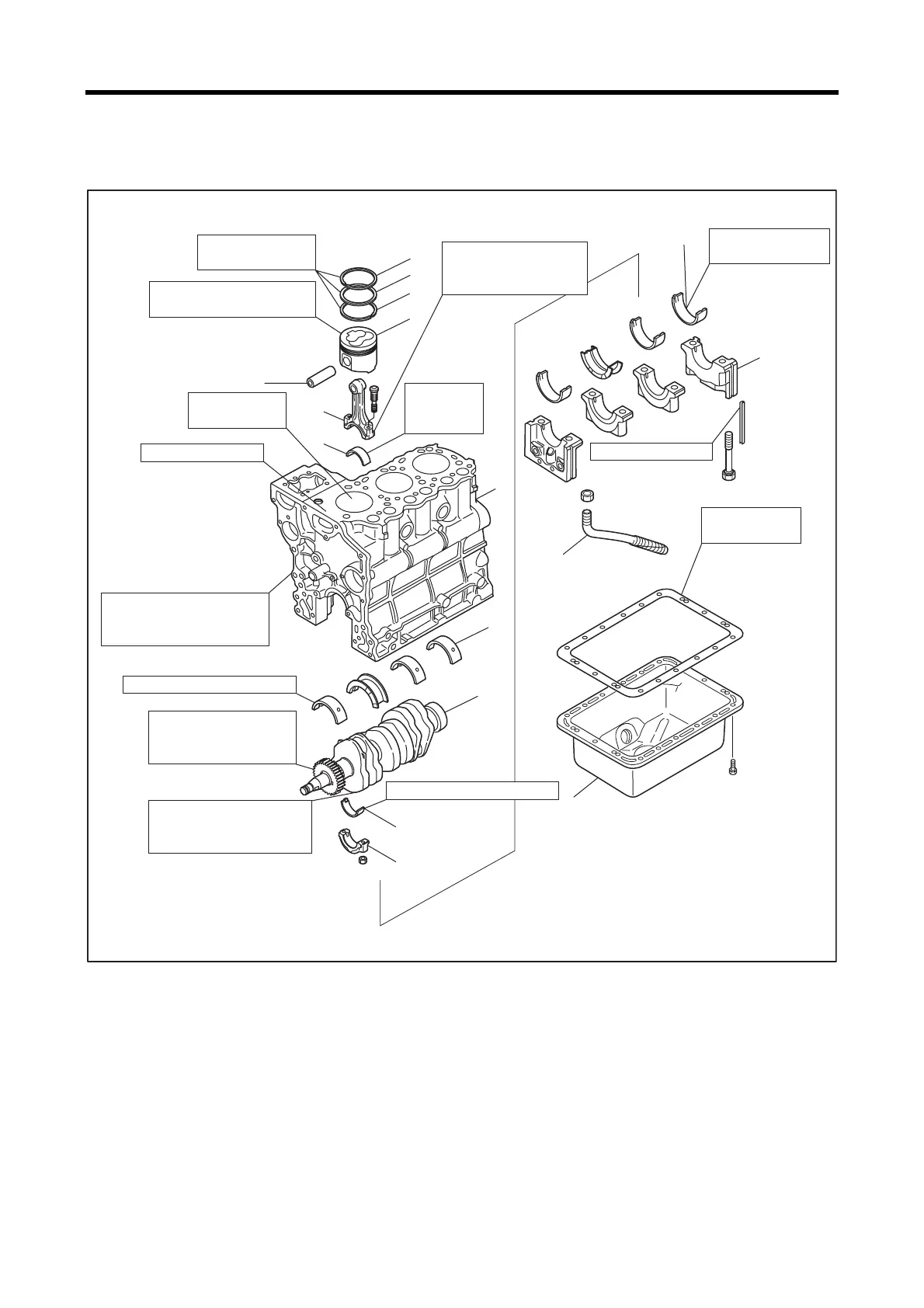

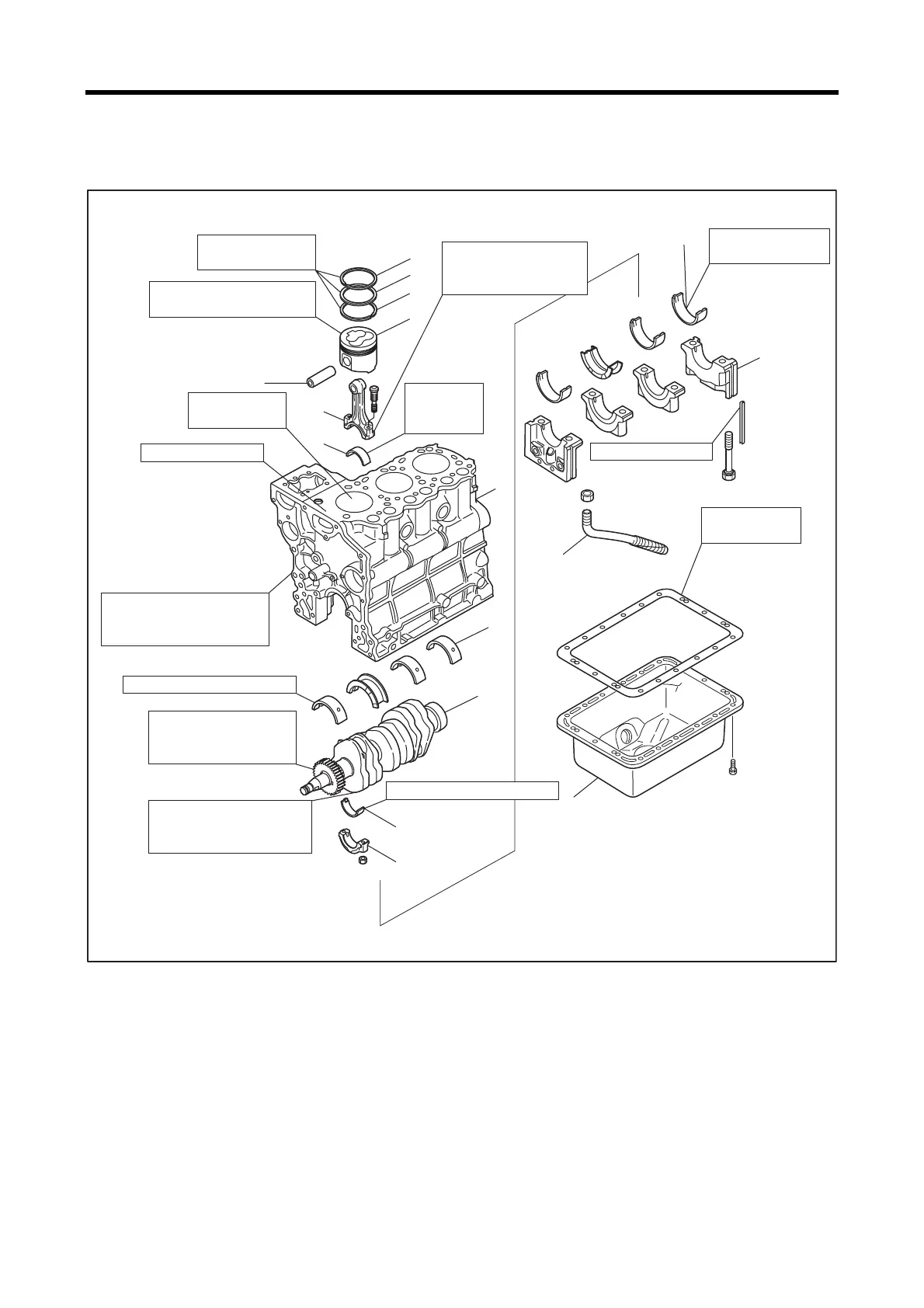

4. Disassembling and inspecting cylinder block, crankshaft, piston and oil pan

Disassembling and inspecting cylinder block, crankshaft, piston and oil pan

Disassembling sequence

Note: When replacing the crankcase, carefully remove parts (relief valve, etc.) mounted on the non-reusable crankcase so that

they can be reused.

1 Oil pan 7 No.1 compression 12 Main bearing cap

2 Oil screen 8 No.2 compression 13 Lower main bearing

3 Connecting rod cap 9 Oil ring 14 Crankshaft

4 Lower connecting rod

bearing

10 Piston

(Remove parts 5 to 10 as a unit)

15 Upper main bearing

16 Cylinder block

5 Connecting rod 11 Upper connecting rod

bearing

6 Piston pin

7

8

9

10

5

6

11

16

15

12

14

4

3

13

2

1

Cylinder flaws,

stepped wear

Flaking, scratches,

seizure

Replace: Side seal

Flaking,

scratches,

seizure

Replace:

Oil pan gasket

Flaking, scratches, seizure

Flaking, scratches, seizure

Crankshaft gear teeth

damage,

sticking to bearing

Journal, pin damage,

local wear, cracks, bend,

clogged oil hole

Plug, dowel pins damage,

clogging or contamination

of oil/water holes

Top face distortion

Piston ring wear,

damage, end gap

Piston wear, sticking,

streaks, ring groove wear

Connecting rod bend,

twist, big end thrust

clearance

Loading...

Loading...