2.85V, connect to VCC of the SD card. If the IO is 1.8V, connect to the VDD_1P8 pin of the

module.

⚫

The recommended supply voltage of VCC ranges 2.85V to 3.0V and current is larger than 500

mA. An LDO or DC-DC is recommended.

⚫

Connect a resistor of 15Ω to 24Ω to SDC_CLK in series.

⚫

The SD card detection function is implemented by the interrupt, which is triggered by level

change at the SDC_DET pin after an SD card is installed in the card connector. As shown in

Figure 3-21, SDC_DET is left floating before an SD card is inserted and grounded after an SD

card is inserted, and the level at SDC_DET changes from high to low.

⚫

Add an ESD protector of lower than 10 pF to each pin. ESD protection diode array is an option.

In Figure 3-21, ESD1 and ESD2 consist of four same ESD protectors.

PCB Design Guidelines

⚫

Place ESD protectors close to SD connector. The pin numbers of ESD arrays can be adjusted in

actual applications.

⚫

The trace of power supply should be wider than 0.5 mm.

⚫

Place the resistor on the CLK line close to the module.

⚫

Control the length difference of DATA, CMD, and CLK signal traces to 1 mm.

⚫

Keep the total length of DATA, CMD, and CLK signal traces to 40 mm.

⚫

Spacing between CMD, CLK, and DATA traces should be larger than 2 times trace width.

⚫

Spacing between CMD, CLK, and DATA traces and other signal traces should be larger than 2

times trace width.

⚫

Control the impedance for CMD, CLK, and DATA traces to 50Ω individually.

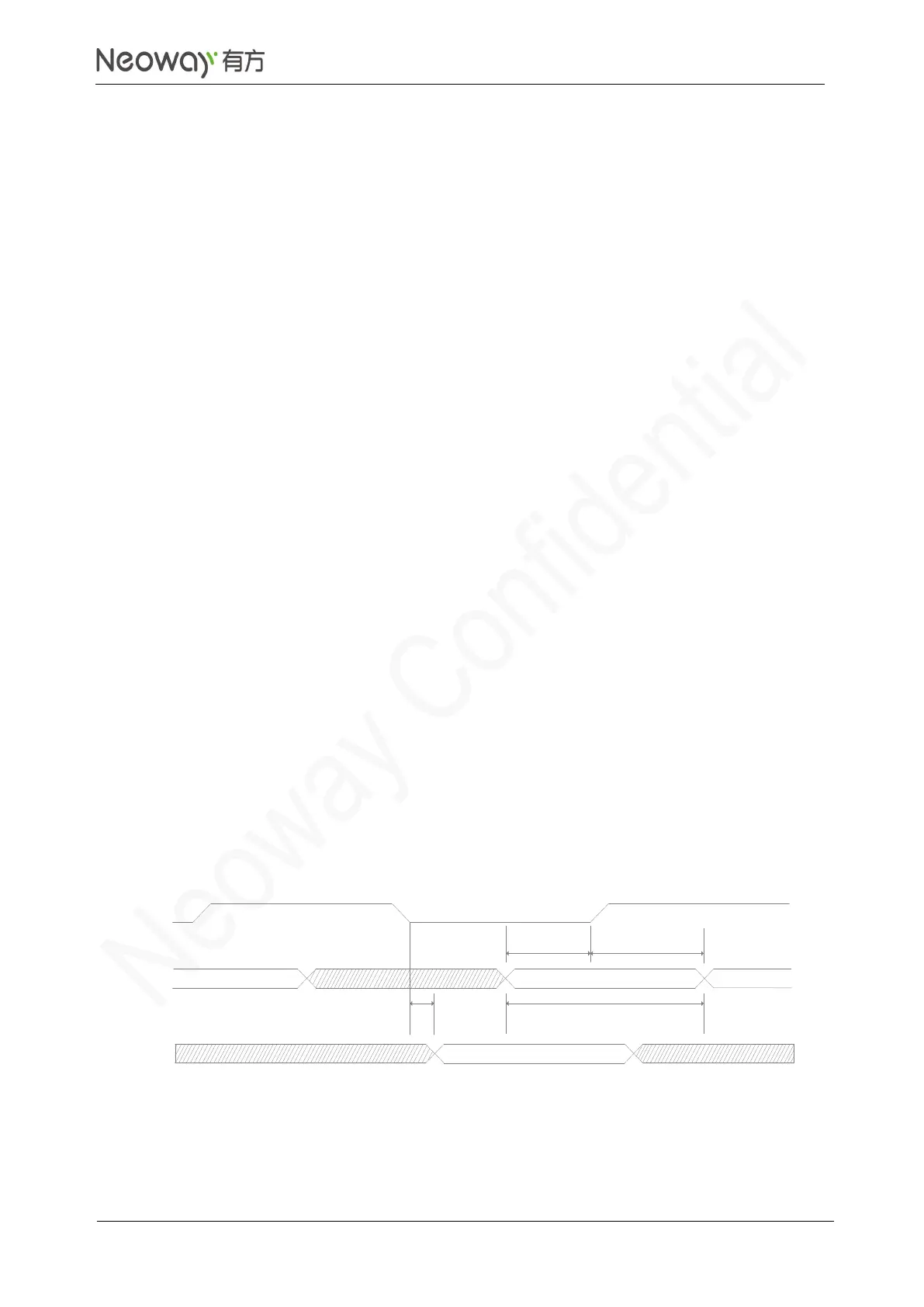

For the timing of the SDC interface in SDR and DDR mode, see Figure 3-22 and Figure 3-23. For

parameter values for the SD interface, see Table 3-4.

Figure 3-22 SDC SDR timing

Loading...

Loading...