6-10

Application Control

In winding systems such as wire drawing machines and spinning machines, the outer diameter of the

wind-up roll increases due to the amount of material being wound onto the roll and the actual wind-up

speed increases when winding is continued at a constant shaft speed. To maintain the wind-up speed

at the outer periphery at a constant speed, a speed sensor is used to detect the wind-up speed, and

the speed of the motor shaft is controlled so that the wind-up speed is kept constant.

6-10-1

Application Control Settings

Set enable/disable status for line speed control and synchronized run operation (simultaneous start

synchronization/standby synchronization).

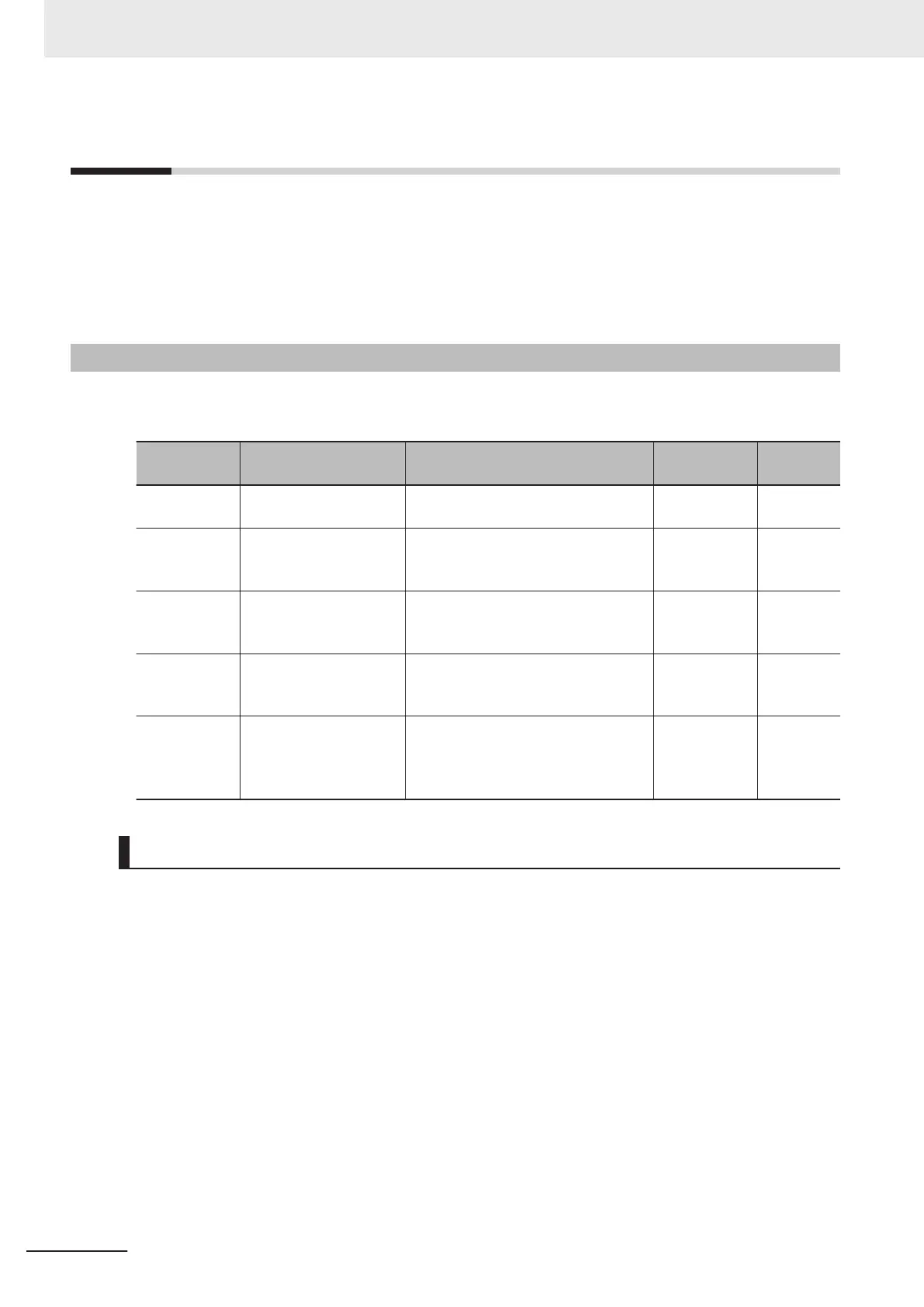

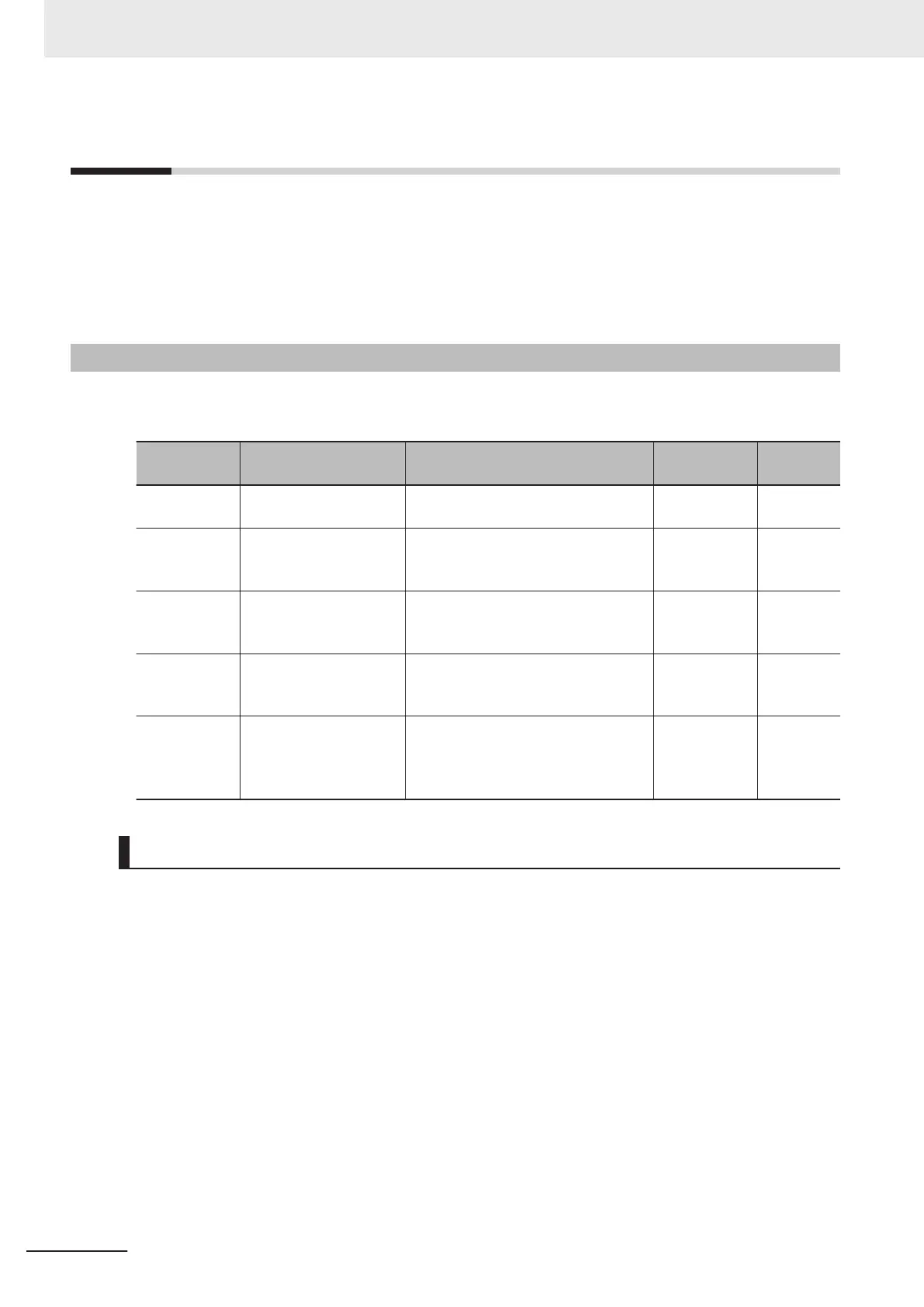

Parameter

No.

Function name Data Default data Unit

d41

Special Control Selec-

tion

1: Line speed control with speed sen-

sor

0 -

d15

Input Terminal [PIA][PIB]

Encoder Pulse Resolu-

tion

20 to 60000 1024 Pulse

d16

Input Terminal [PIA][PIB]

Pulse Scaling Factor

Denominator

1 to 32767 1 -

d17

Input Terminal [PIA][PIB]

Pulse Scaling Factor

Numerator

1 to 32767 1 -

E01 to E05,

E98, E99

Input Terminal [DI1]

Function Selection to In-

put T

erminal [DI7] Func-

tion Selection

70: Line speed control cancellation

71: Line speed control frequency

memory

- -

Machine Configuration and Settings

The following parameters must be set when the mechanical system of a winder is configured as

shown in the figure below.

6 Vector Control and Applied Functions

6-78

M1 Series Standard Type User's Manual (I669)

Loading...

Loading...