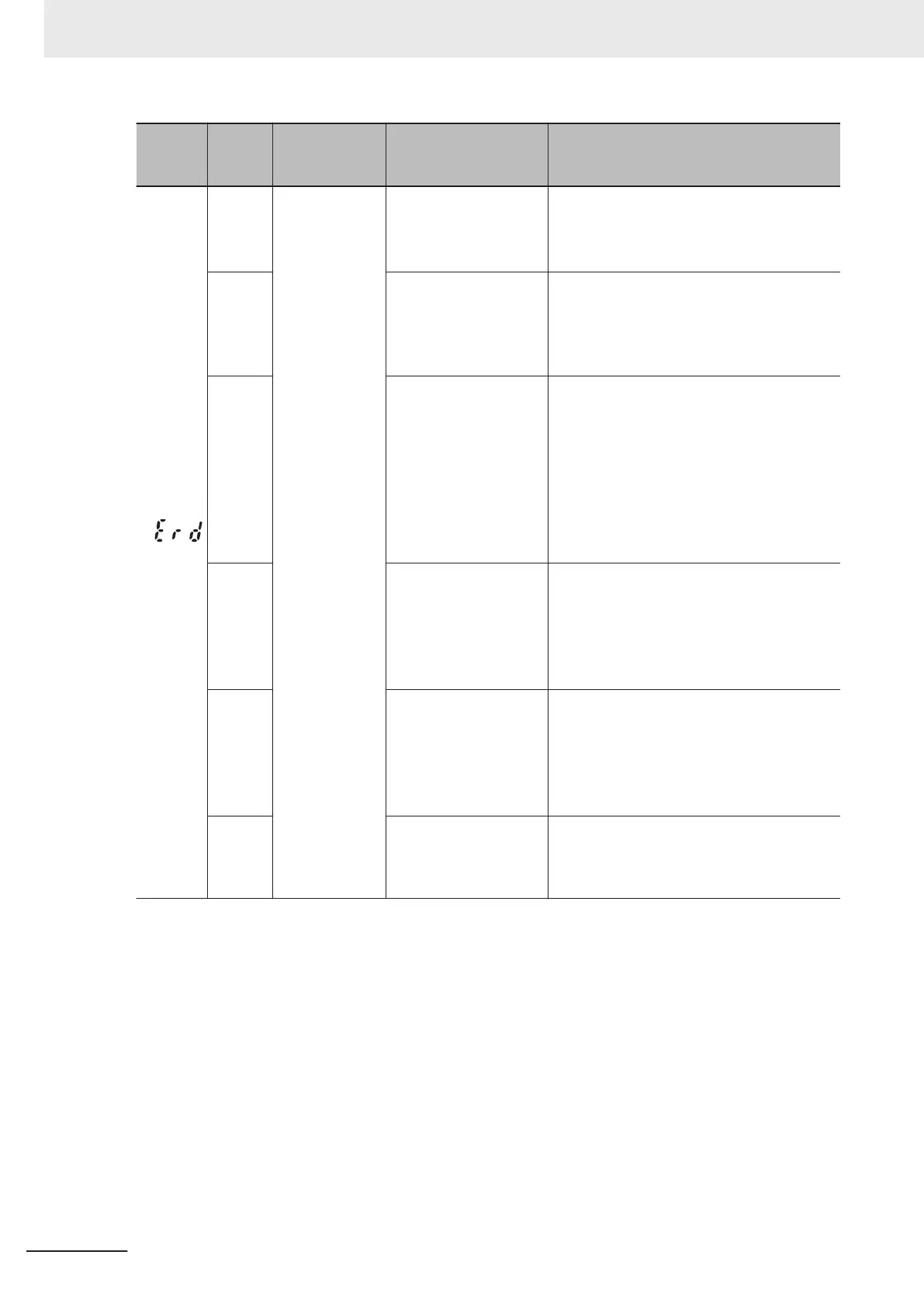

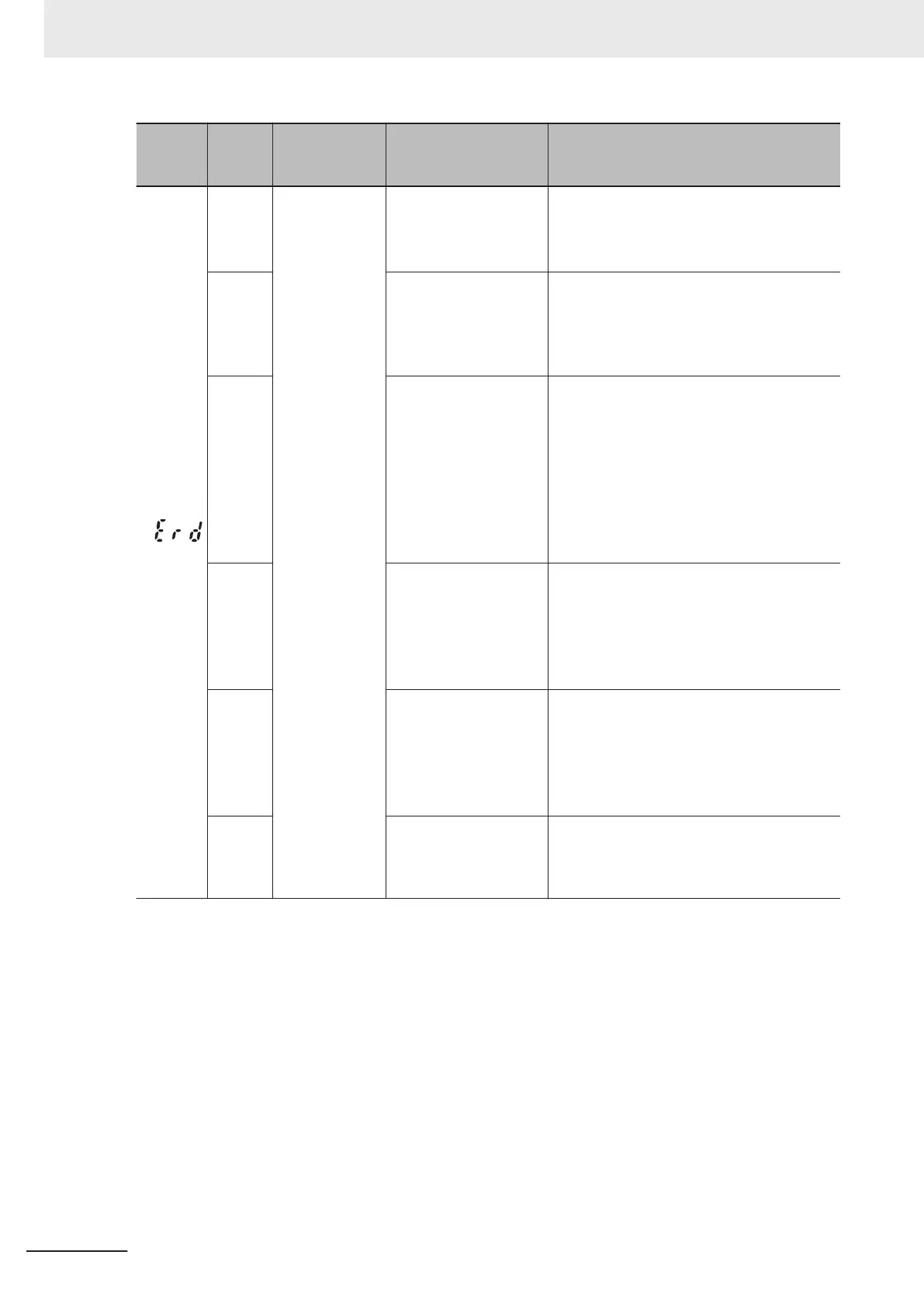

Alarm

code

Alarm

sub-

code

Name Description Check point and remedy reference

(Erd)

Stall detection/

startup magnet-

ic pole position

detection failure

(1) Different motor char-

acteristics

Check that parameter

(F04,F05,P01,P02,P03,P60,P61,P62,P63,P6

4) data matches motor constants.

→ Perform auto tuning.

(2) Magnetic pole posi-

tion detection method is

not appropriate

Check that the magnetic pole position detec-

tion method matches the motor type.

→ Match the magnetic pole position de-

tection method (parameter P30) selec-

tion to the motor type.

(3) Insufficient starting

frequency (holding

time) (parameter F24)

Check that, when setting the magnetic pole

position detection method selection (parame-

ter P30*) to 0 or 3, the starting frequency

(holding time) (parameter F24) is set opti-

mally

.

→ Set a time that enables the motor to ro-

tate one revolution or more.

F24 ≥ P01/2/F23 (P01: pole, F23: start-

ing frequency)

(4) Insuf

ficient starting

torque

Check acceleration time (parameter F07,

E10, E12, E14) and reference current at

starting (parameter P74) data.

→ Set an acceleration time that matches

the load.

→ Raise the reference current at starting.

(5) Low braking load Check reference current at starting (parame-

ter P74*) data.

→ Lower the reference current at starting.

When a motor is run on its own, such

as during a test run, set to 80% or low-

er

.

(6) The connection be-

tween the inverter and

the motor is missing

phases

→ Ensure a correct connection between

the inverter and motor.

9 Troubleshooting

9-10

M1 Series Standard Type User's Manual (I669)

Loading...

Loading...