2-10

2

* The wire thickness is set for copper wires at 75°C.

F7Z4185

R/L1, S/L2, T/L3

M16 78.4 to 98

95 to 300

(4/0 to 600)

150 × 2P

(300 × 2P)

Power cables,

e.g., 600 V vinyl

power cables

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L33

120 × 2P

(250 × 2P)

, 1

300 × 2P

(600 × 2P)

3

–

95 × 2P

(3/0 × 2P

r/l1, Δ200/

l2

200, Δ400/

l2

400

M4 1.3 to 1.4

0.5 to 4

(20 to 10)

1.5

(16)

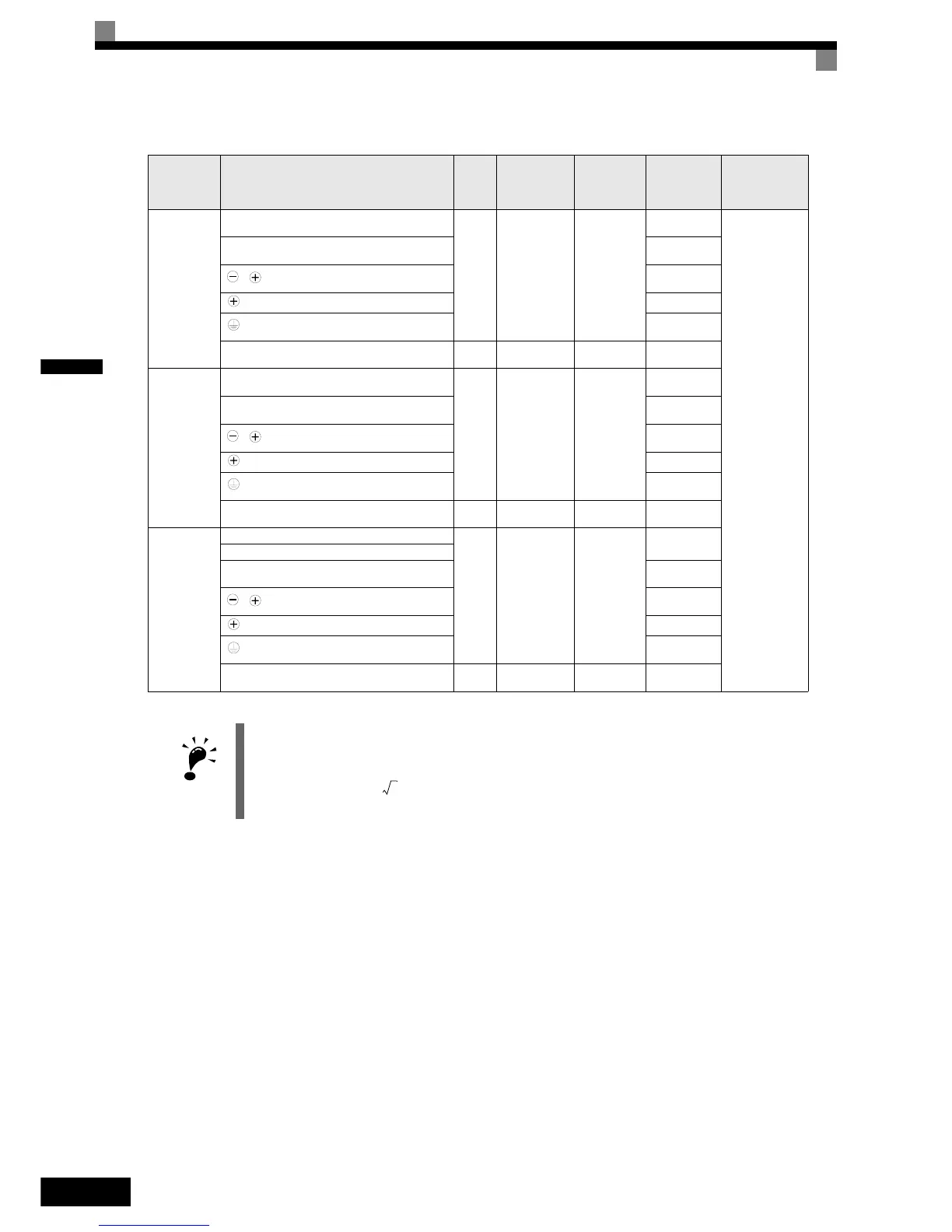

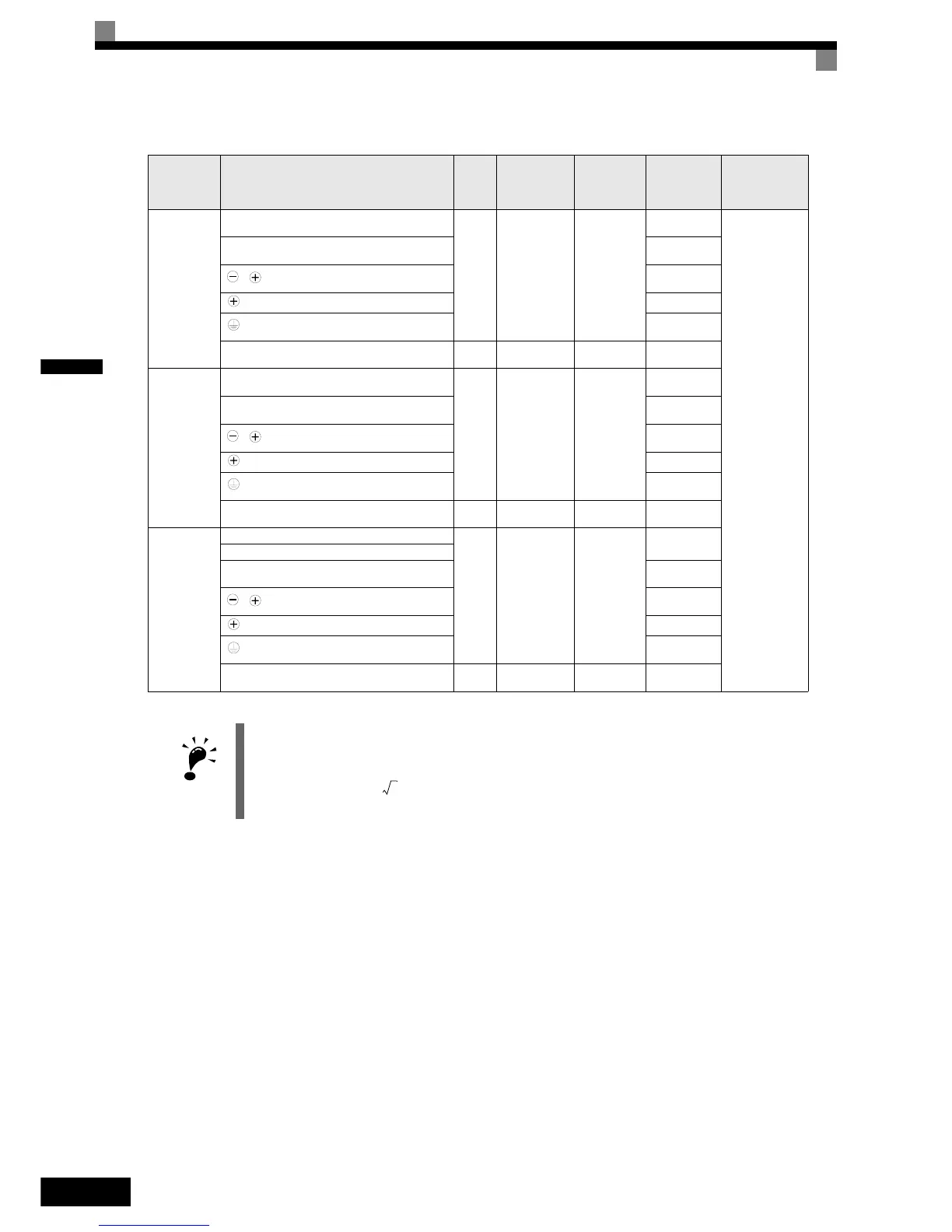

F7Z4220

R/L1, S/L2, T/L3

M16 78.4 to 98

95 to 300

(4/0 to 600)

240 × 2P

(500 × 2P)

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L33

240 × 2P

(400 × 2P)

, 1

120 × 4P

(250 × 4P)

3

–

120 × 2P

(250 × 2P)

r/l1, Δ200/

l2

200, Δ400/

l2

400

M4 1.3 to 1.4

0.5 to 4

(20 to 10)

1.5

(16)

F7Z4300

R/L1, S/L2, T/L3

M16 78.4 to 98

95 to 300

(4/0 to 600)

120 × 4P

(250 × 4P)

R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/T3

120 × 4P

(4/0 × 4P)

, 1

240 × 4P

(400 × 4P)

3

–

120 × 2P

(250 × 2P

r/l1, Δ200/

l2

200, Δ400/

l2

400

M4 1.3 to 1.4

0.5 to 4

(20 to 10)

1.5

(16)

IMPORTANT

Determine the wire size for the main circuit so that line voltage drop is within 2% of the rated voltage.

Line voltage drop is calculated as follows:

Line voltage drop (V) =

x wire resistance (W/km) x wire length (m) x current (A) x 10

-3

Table 2.2 400 V Class Wire Sizes

Inverter

Model

CIMR-

Terminal Symbol

Termi-

nal

Screws

Tightening

Torque

(N•m)

Possible

Wire Sizes

mm

2

(AWG)

Recom-

mended Wire

Size mm

2

(AWG)

Wire Type

3

Loading...

Loading...