Sealing

47

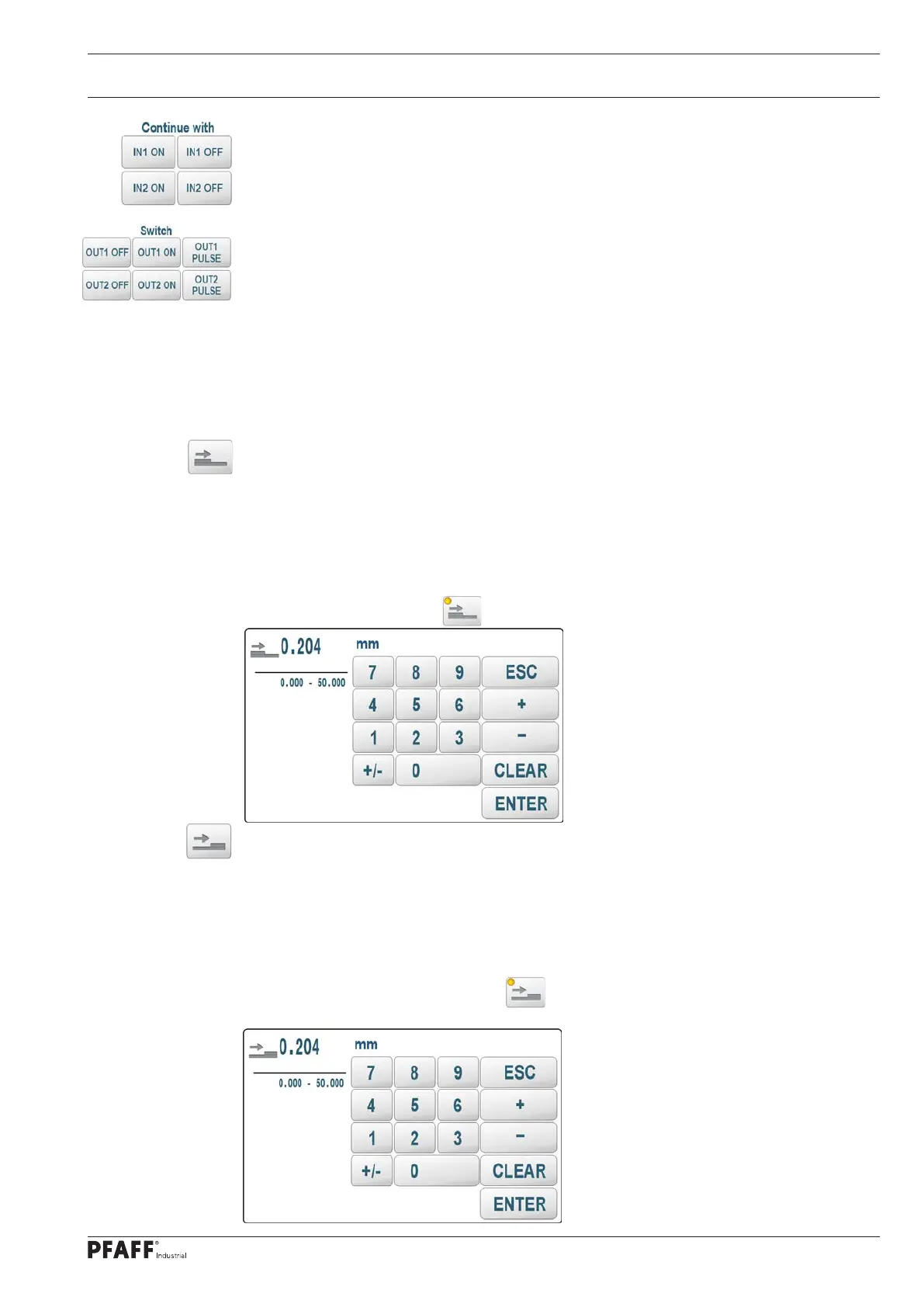

Determine the input level of the inputs IN1 (X3 / PIN2) and / or IN2 (X3 / PIN3) as a step

enabling condition with high level: IN1,2 ON or with LOW level: IN1,2 OFF. If both inputs are

used, the first matching input level switches to the next range.

Switch the outputs OUT1 (X12 / PIN1) and / or OUT1 (X12 / PIN3) directly.

OUT1,2 ON: 24V (active)

OUT1,2 OFF: 0V (passive)

OUT1,2 PULSE: Output for 300ms (parameter OUT1,2Pulsetime; see S40) to 24V - then

switch off to 0V

The outputs are switched immediately at the beginning of the area processing. They do not

contribute to the switching to the next area. For this reason, another area switching must

also be defined. This is usually the condition that would apply in the next area anyway.

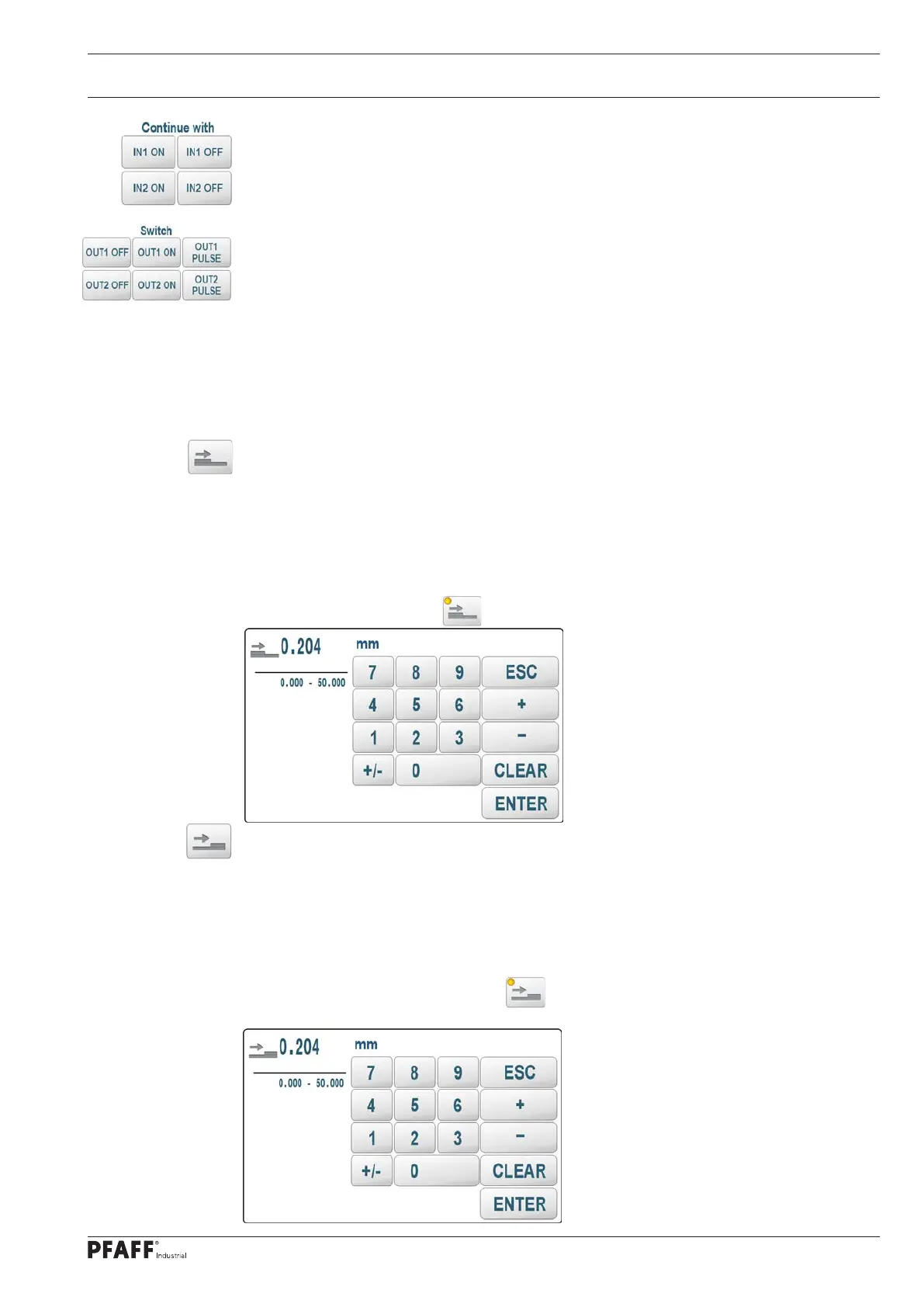

Layer reduction (PLY-)

By pressing the key, an input screen is opened with which the material thickness difference

is entered, which leads to the range switching. The machine continuously determines the

distance between the transport rollers. The reference distance for this area is determined

200ms after the start of the roll or an area switchover. If the current distance later deviates

from the reference distance by the entered value, the system switches to the next area or

the program ends at the last area. The activated function can be recognized in the editor by

the LED on the function key .

Layer gain (PLY +)

By pressing the key, an input screen is opened with which the material thickness difference

is entered, which leads to the range switching. The machine continuously determines the

distance between the transport rollers. The reference distance for this area is determined

200ms after the start of the roll or an area switchover. If the current distance later deviates

upwards from the reference distance by the entered value, the system switches to the next

area or the program ends at the last area. The activated function can be recognized in the

editor by the LED on the function key .

.

Loading...

Loading...