Phoenix LT4 Lane Machine Operation, Maintenance, and Parts Manual

4-32 Rev. Date: 01/22 61-900040-000

TIP

When cutting new wicking foams from a section of factory bulk length, cut and

discard approximately 1/2" from the factory cut edge. Failure to do so could

result in inconsistent oil flow through the wicking foam at the end.

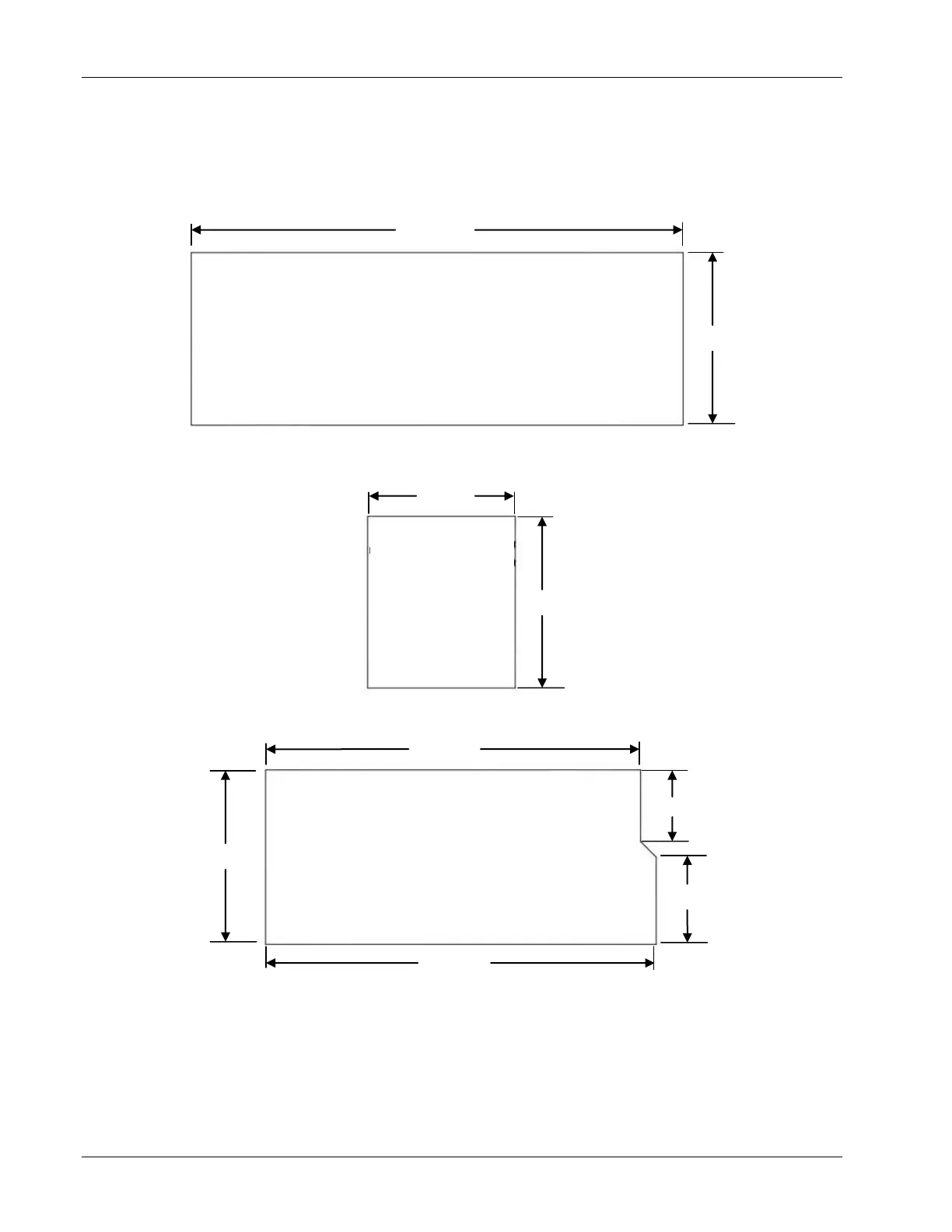

Figure 4- 317

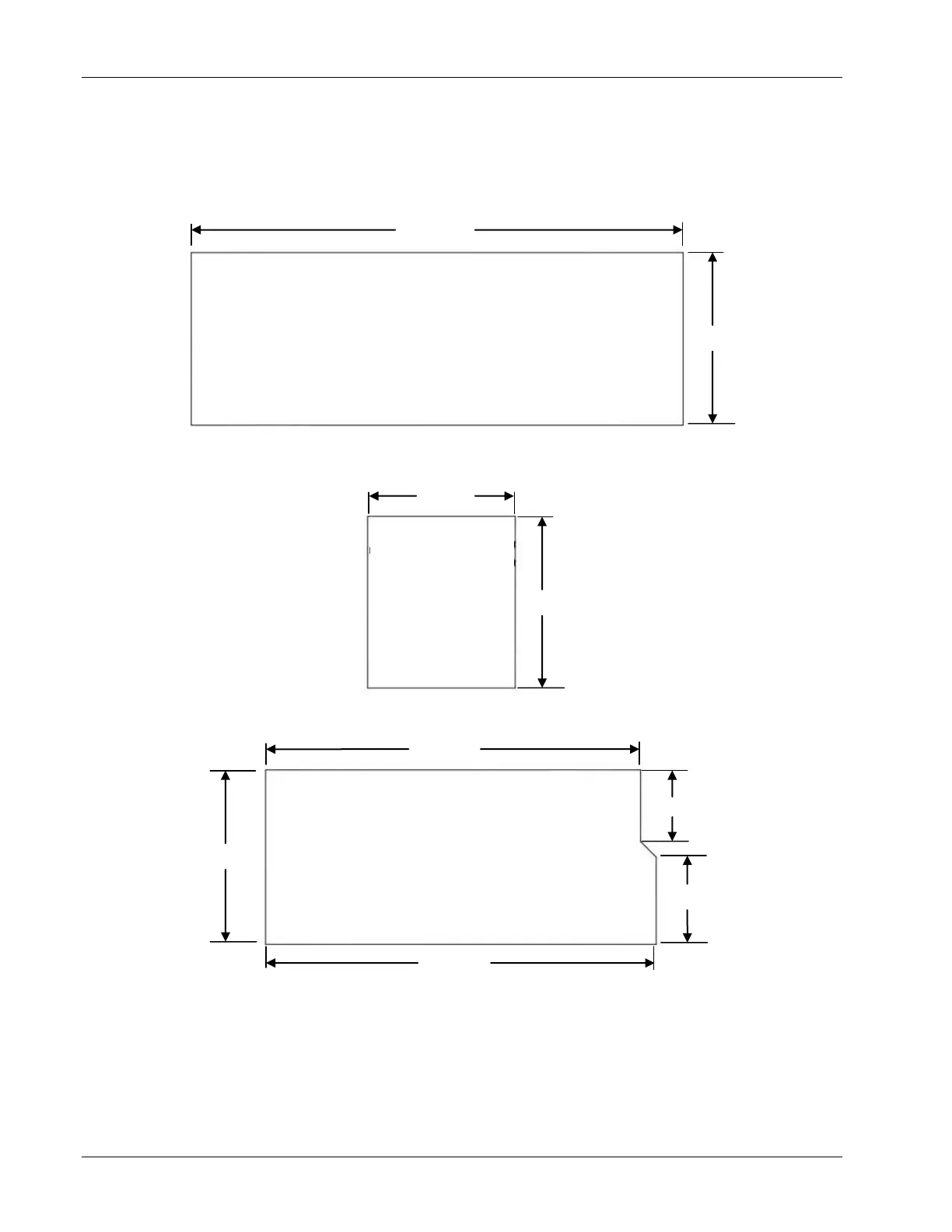

Figure 4- 328

Figure 4- 339

The end foams should be profiled like the original factory foams, as shown in Figure 4-

339 to prevent dripping. A wick-cutting template (P/N 294-080-201) can be purchased

from Brunswick. Different oil patterns can be created by using different foam densities in

the oil tank. For more on oil patterns, see Section 6 – Determining the Oil Pattern.

Loading...

Loading...