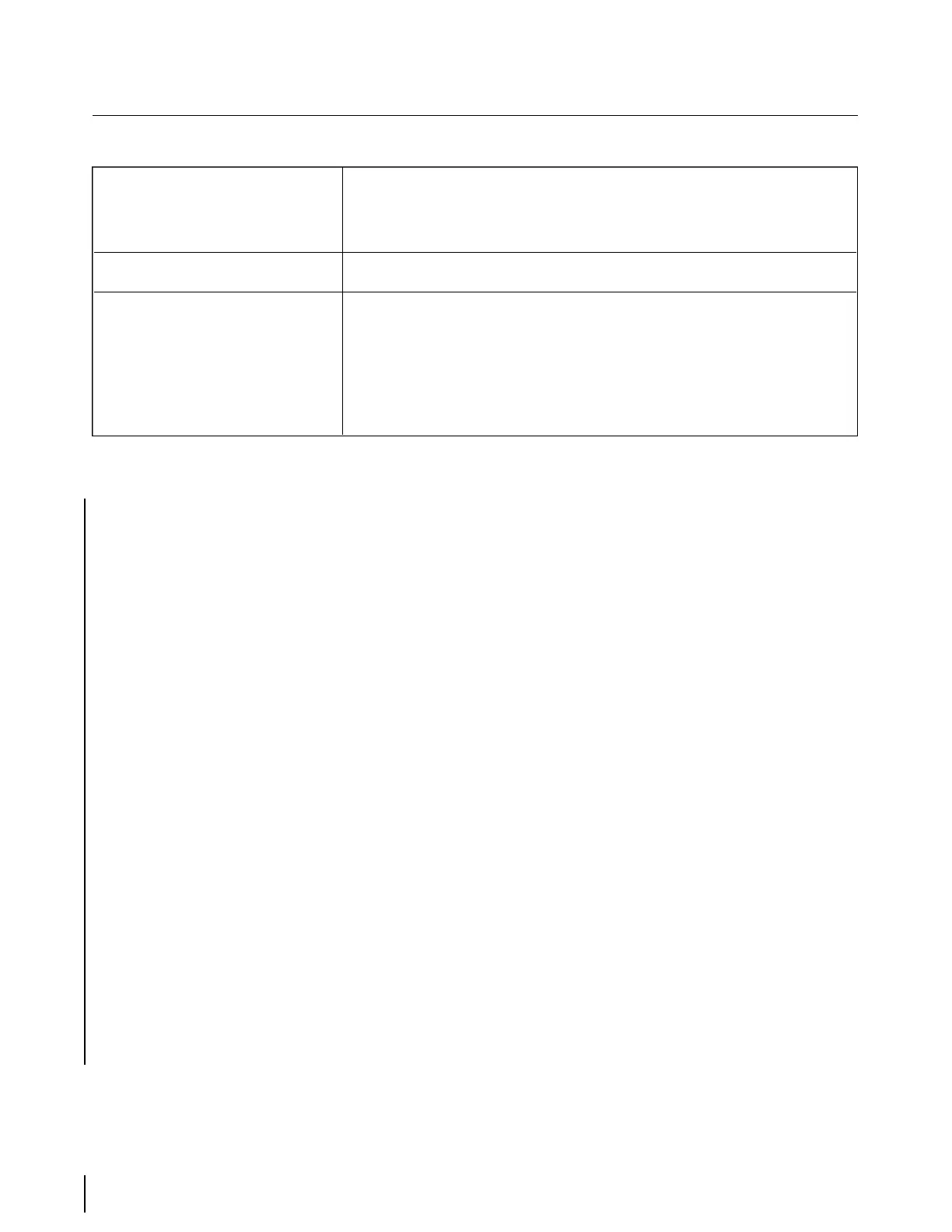

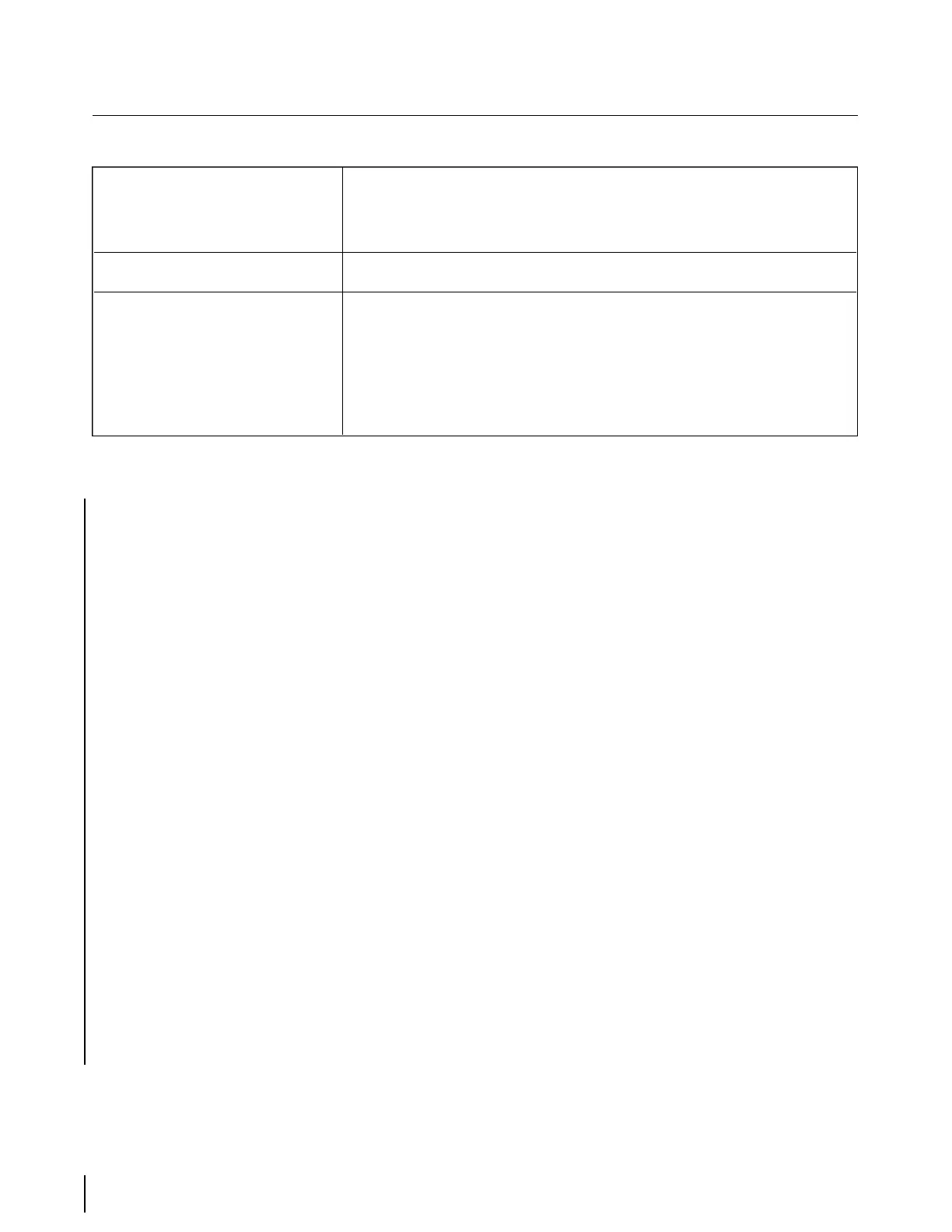

TABLE VIIIA-I. PROPELLER SPECIFICATIONS

Hartzell McCauley

Blade Angle* Low Pitch (High RPM) 14.0° ± 0.2° 12.5° ± 0.2°

*Measured at 30 inch station. High Pitch (Low RPM) 29.0° ± 2° 27.5° ± 0.5°

Propeller RPM Setting Engine Static High RPM 2700 RPM Max.

Propeller Torque Limits Description Required Torque (Dry)

Propeller Mounting Nuts 60-70 foot-pounds (Hartzell)

55-65 foot-pounds (McCauley)

Forward Bulkhead Attachment Bolts 30-35 inch-pounds (Hartzell)

Aft Bulkhead Attachment Bolts 50-70 inchpounds

Spinner Attachment Screws 20-25 inch pounds

8A-13. ENGINE.

8A-13a.INSTALLATION OF BUSHINGS AND PINS FOR FIBERGLASS TYPE COWLINGS.

a. With cowlings removed, locate bushings on lower cowling. (See Figure 8A-3a.)

b. Using snap ring pliers, remove snap ring and old bushing.

c. Install new bushing and new snap ring.

NOTE

Bushings should be inspected each 100 hours and should be

replaced upon condition, but no later than 500 hours time in

service.

d. Locate pins in upper cowling.

NOTE

It should not be necessary to replace the pins unless bushing in

lower cowling has worn enough to allow damage to the pin. Any

noticeable notching or cutting of the pin requires replacement.

e. If it is necessary to remove the pins, appropriate tools should be used to remove the fiberglass resin

from around the pin and plate assembly. (A template or adequate measurements should be made to assure

proper alignment of the new pin and plate assembly.)

f. Remove pin and plate assembly

g. To install new pin and plate assembly it will be necessary to prepare the fiberglass surface to accept

the new plate. (See Paragraph 4-56, FIBERGLASS REPAIRS.)

1. Clean area as required, and roughen.

2. Prepare cowling surface by applying resin. Do not allow to harden.

3. Install plate and pin.

4. Lay in a layer of resin impregnated fiberglass cloth over the plate and surrounding fiberglass. (Use

template or measurements from step e to assure alignment.) Allow to cure.

Interim Revision: 2/21/95

2D1

CHEROKEE ARROW III SERVICE MANUAL

POWER PLANT - LYCOMING

Loading...

Loading...