69

Section 10 Troubleshooting

10.1 Possible sources of the problem

This list gives you an idea of where to look for problem solving if you are having problems with

your analyzer.

10.2 Possible solutions

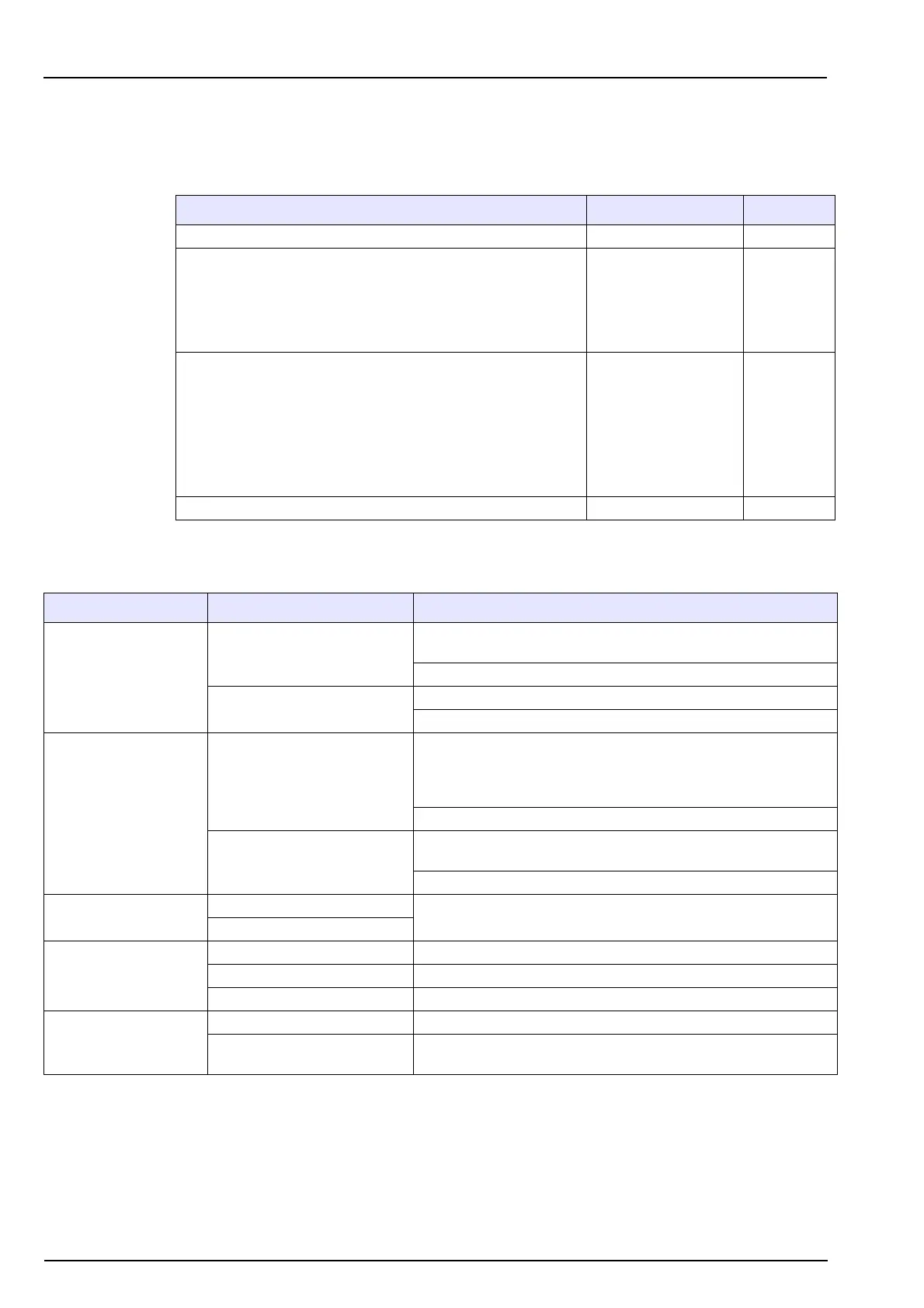

Problem Possible cause Problem N°

The system does not run Start / Stop 1

The measurement is not stable, too high or too low

Sample

Tubes

Photometer

Valves

Pump

5

3

8

4

2

Incorrect calibration

Pump

Tubes

Valves

Calibration solution

Calibration program

Reagents

Photometer

2

3

4

6

7

7

8

The photometer does not run or measure correctly Photometer 8

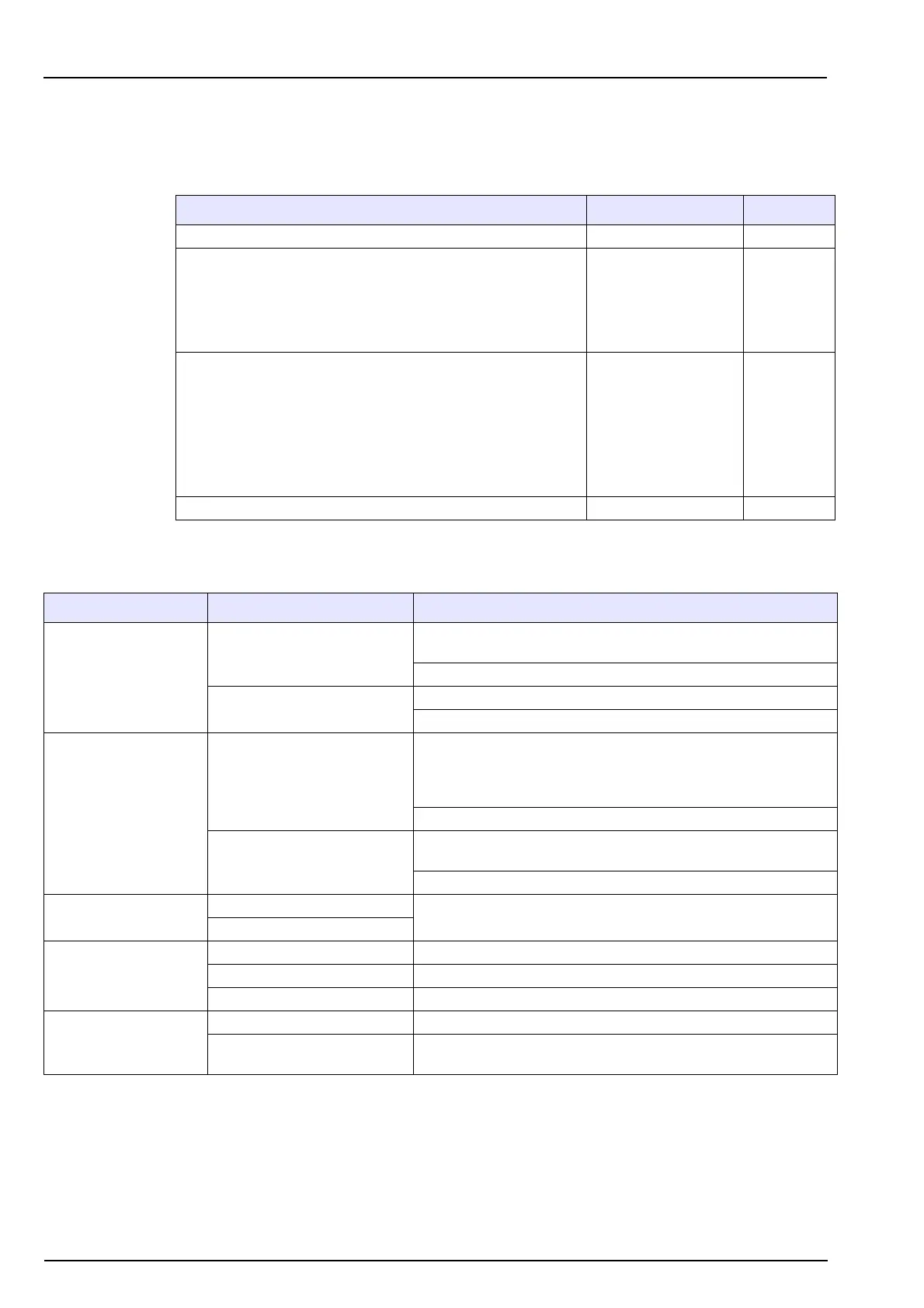

Problem Symptom Solution

1. START / STOP

Analyzer stopped

System alarm: Rectify the problem according to the message

displayed (see Table 2 on page 46).

Start up the analyzer by pressing the Start key.

Mains power cut off

Connect the analyzer to the mains power.

Check the fuse.

2. PUMP

Does not run

Test the pump. In the MAINTENANCE / PUMP - OTHERS menu

the number of pulses is automatically set to 1,000. Start each

pump one after the other and verify that the volume obtained per

pump is between 2.5-3 mL (corresponding to 2.5-3 μL/pulse).

Change the pump.

Irregular

The analyzer may have been stopped without cleaning the tubes.

Using a syringe, flush the pump with clean water.

Change the pump.

3. TUBES

Defective tube

Change the tube.

Clogged tube

4. SOLENOID VALVES

Solenoid valves leak Remove, test and clean.

The solenoid valves can't open Stuck membrane; cleaning required.

The solenoid valves can't close Blocked outlet; cleaning required.

5. SAMPLE

Dirty Disconnect the sample lines from the sample block.

Diminution of the flow

Verify and adjust the flow (10 L/h), change the sample tube if it is

clogged.

Loading...

Loading...