Operation and Maintenance Manual Rev M(ii) 4/03

- 40 -

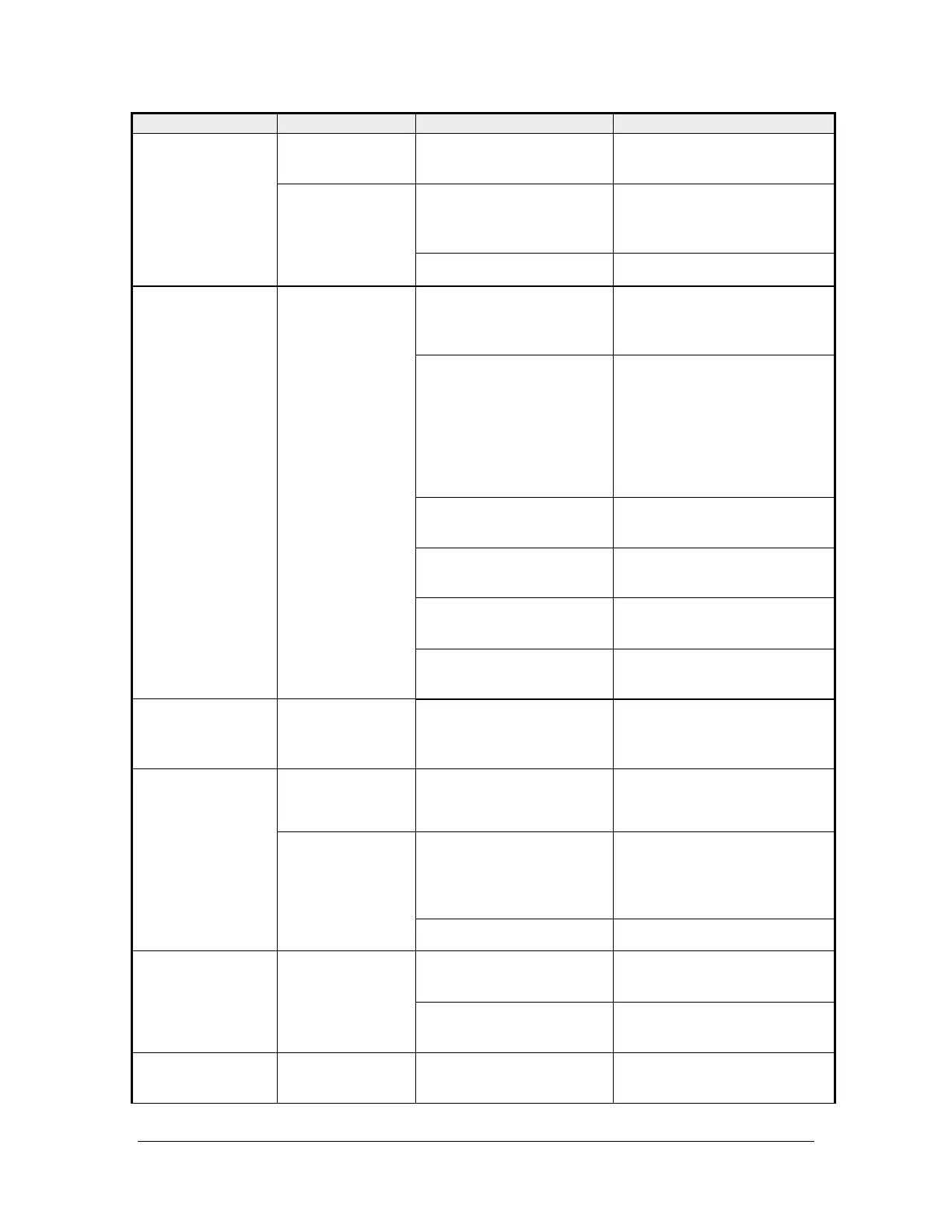

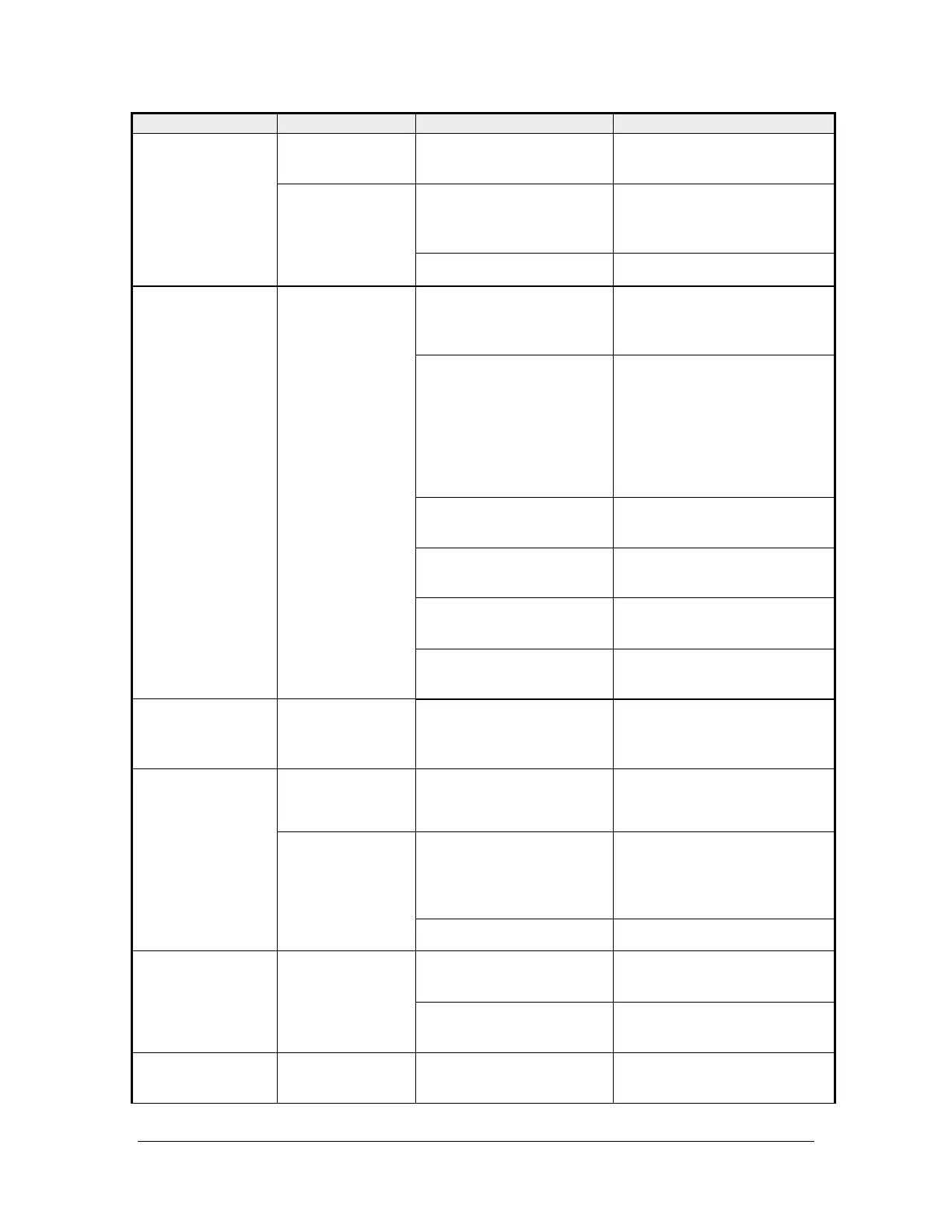

Operation Other Symptoms Possible Cause Corrective Action

Axis runs away. Motor power connections

are wired incorrectly.

• Check the phasing using the

electrical drawings.

Z axis encoder

does not work.

Z axis encoder/brake cable

is loose or not connected.

• Check the cable

connections. Correct any

loose connections.

The axis amplifier is bad.

• Replace the amplifier.

Pneumatic actuator

failure.

Pneumatics work

slowly.

Air lockout valve on the rear

of the machine is in the OFF

position.

• Turn the lockout valve to

the ON position.

Insufficient air pressure.

• Check and adjust the system

pressures to the correct

values. Please refer to the

Machine Specific

Information section of the

Operating Guide for

particular pressure settings.

Restricted air line.

• Correct any tight bends or

restrictions in the air lines.

Loose Fitting or Tubing

Connection.

• Tighten connection.

Frayed or damaged air line.

• Replace the damaged air

line(s).

Sensor is not positioned

correctly.

• Adjust the sensor location.

Part in place sensor

failure.

Cable is loose or not

connected.

• Check the cable

connections. Correct any

loose connections.

Conveyor does not

run.

Conveyor belt stuck to rails.

• Clean or replace belt.

No power to

conveyor motor.

Control relay not energized

or Power On light not

illuminated (Certain

Models).

• Check voltages and

connections.

• Check conveyor power fuse.

Exhaust fan does

not run.

No air flow. The motor overload relay,

OL-1, is in the tripped state.

• Reset the exhaust fan

overload relay.

• Check FU-5 in the electrical

enclosure.

Insufficient air flow capacity

in the factory ducting.

• Upgrade the duct to allow

for more air flow.

Loading...

Loading...