36©2006 Sunrise Medical

POWER BASE SECTION

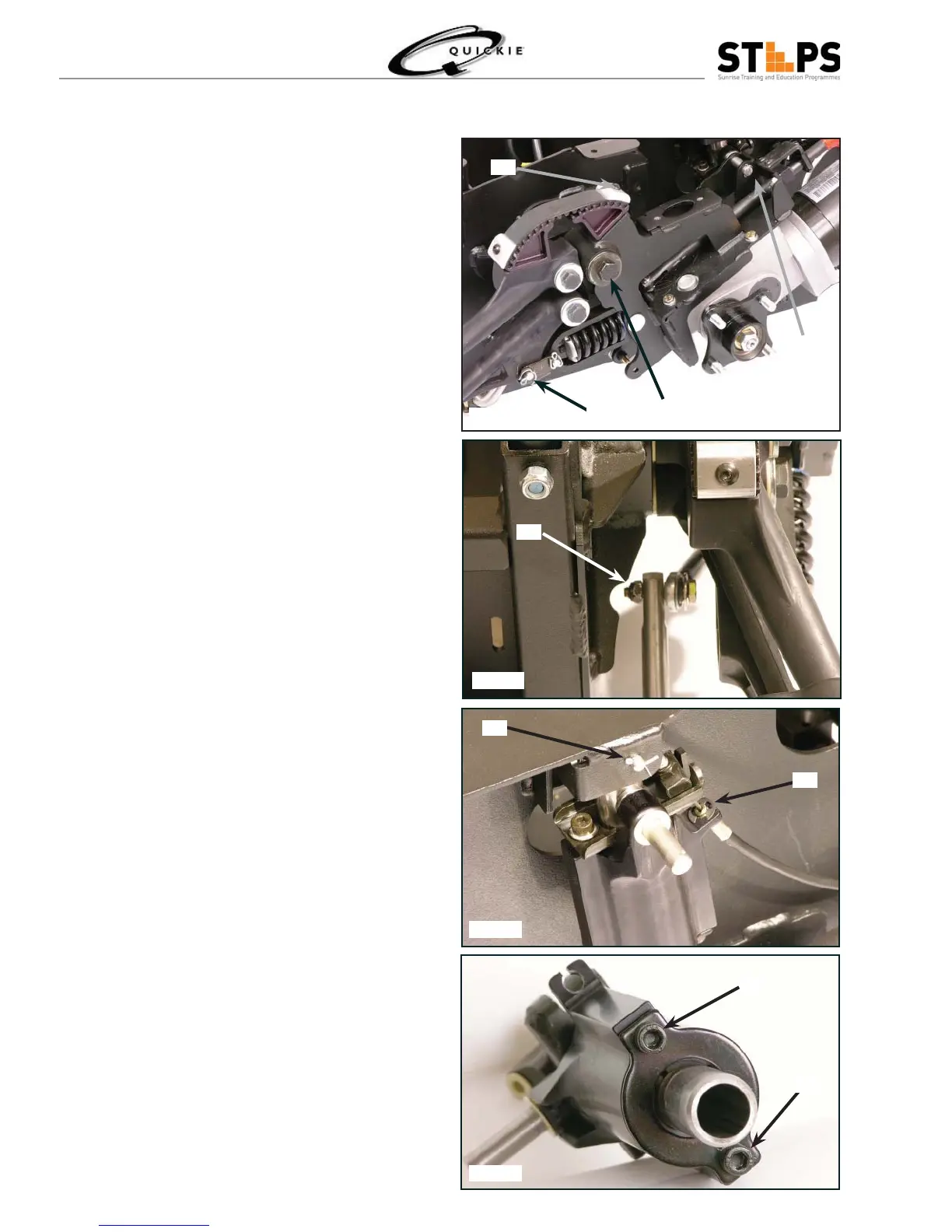

Anti-pitch Damper Mechanism Cleaning

If the Anti-Pitch Mechanism becomes contaminated

with grease or oil it will be necessary to remove and

disassemble it for cleaning.

Raise the chassis of the chair on a stable •

platform, such as jack stands, so that all wheels

are off of the working surface.

Disconnect the motor power lead from the •

controller and remove the motor wiring through

the chassis so that the motor assembly can be

removed from the chair chassis.

Remove the side shroud and set aside. (Refer •

to Shrouds section for removal instructions)

With the motor cog release engaged, loosen •

and remove the drive wheel securing lug nuts

and the drive wheel. (Refer to Drive Wheels

section for instructions)

Remove the front most cotter pin (A) on the •

suspension linkage.

Remove the small cotter (B) pin on the Anti-•

Pitch Damper post.

Remove the main motor assembly bolt (C).•

Remove the button head cap screw (D) that •

holds the belt clamp and belt to the motor mount

pulley.

Use a 10 mm wrench to remove the M6 bolt •

(E) attaching the Anti Sway bar to the Motor

assembly.

Pull the motor assembly away from the chassis •

using a rocking motion.

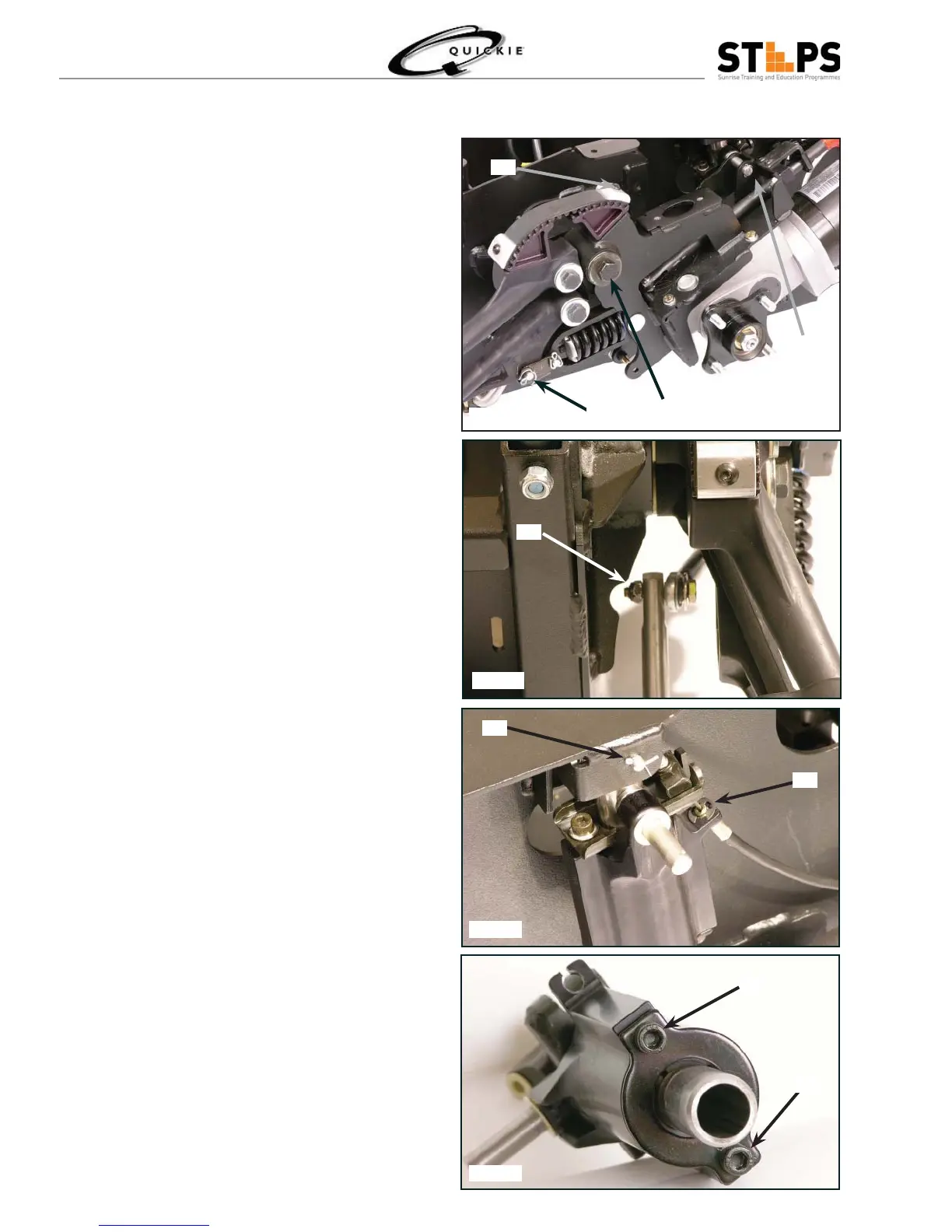

Remove the 1/6 x 1/2 cotter pin (F) and the •

Anti-Pitch Damper Rod Pivot Pin that secure

the Anti-Pitch assembly to the chassis.

Remove the E-clip (G) that holds the cable to •

the Anti-Pitch assembly

Remove the two socket head cap screws (H)on •

the bottom of the Anti-Pitch assembly

During reasembly the two socket head cap •

screws (H) should be torqued to 7-9 foot-

pounds or 10-12 newton-meters. The M6 bolts

(E) that attach the Anti sway bar to the Motor

assembly should be torqued to 6 ft-lbs or 8.13

Newton Meters. The Main Motor Bolt (C) should

be torqued to 55-60 Newton Meters (40-.60 ft-

lbs)

A

B

C

D

E

F

G

H

H

Fig 1.64

Fig 1.65

Fig 1.66

Fig 1.67

Loading...

Loading...