Beijing RichAuto S&T Co., Ltd.

Forging ahead and determined to win 13

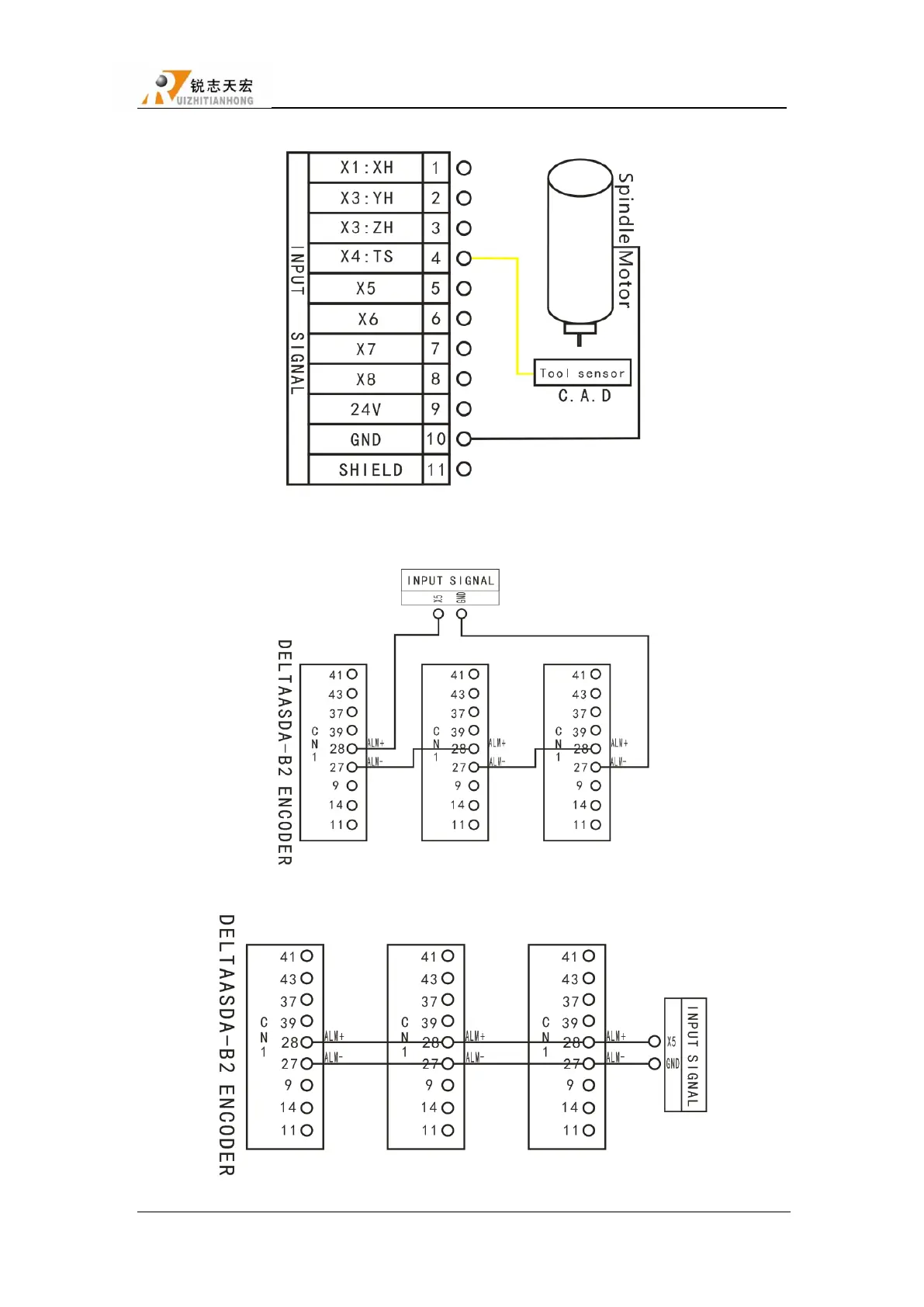

2. Tool-setting input

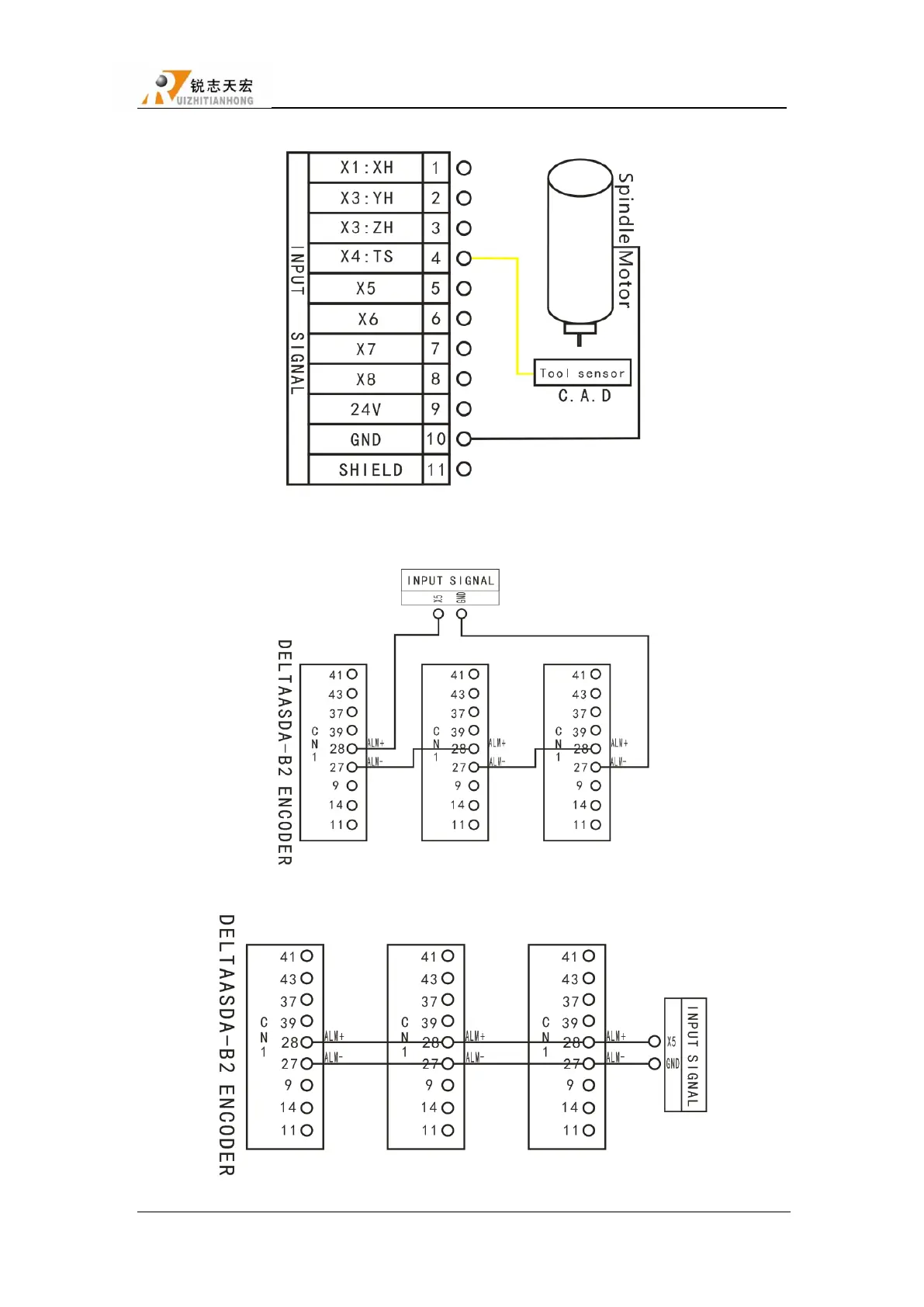

3. X5-X8 e.g.-Servo alarm

Alarm signal normal open,wiring in series(modify the definition of X5 level.

Alarm signal normal open, wiring in parallel

Loading...

Loading...