Beijing RichAuto S&T Co., Ltd.

Forging ahead and determined to win 42

processing file, the system will display total processing time. Different processing speed will

correspond to different processing time.

5.6.8 Find break no

If fail or forget to save the breakpoint,but not change work origin,after changing new tool,

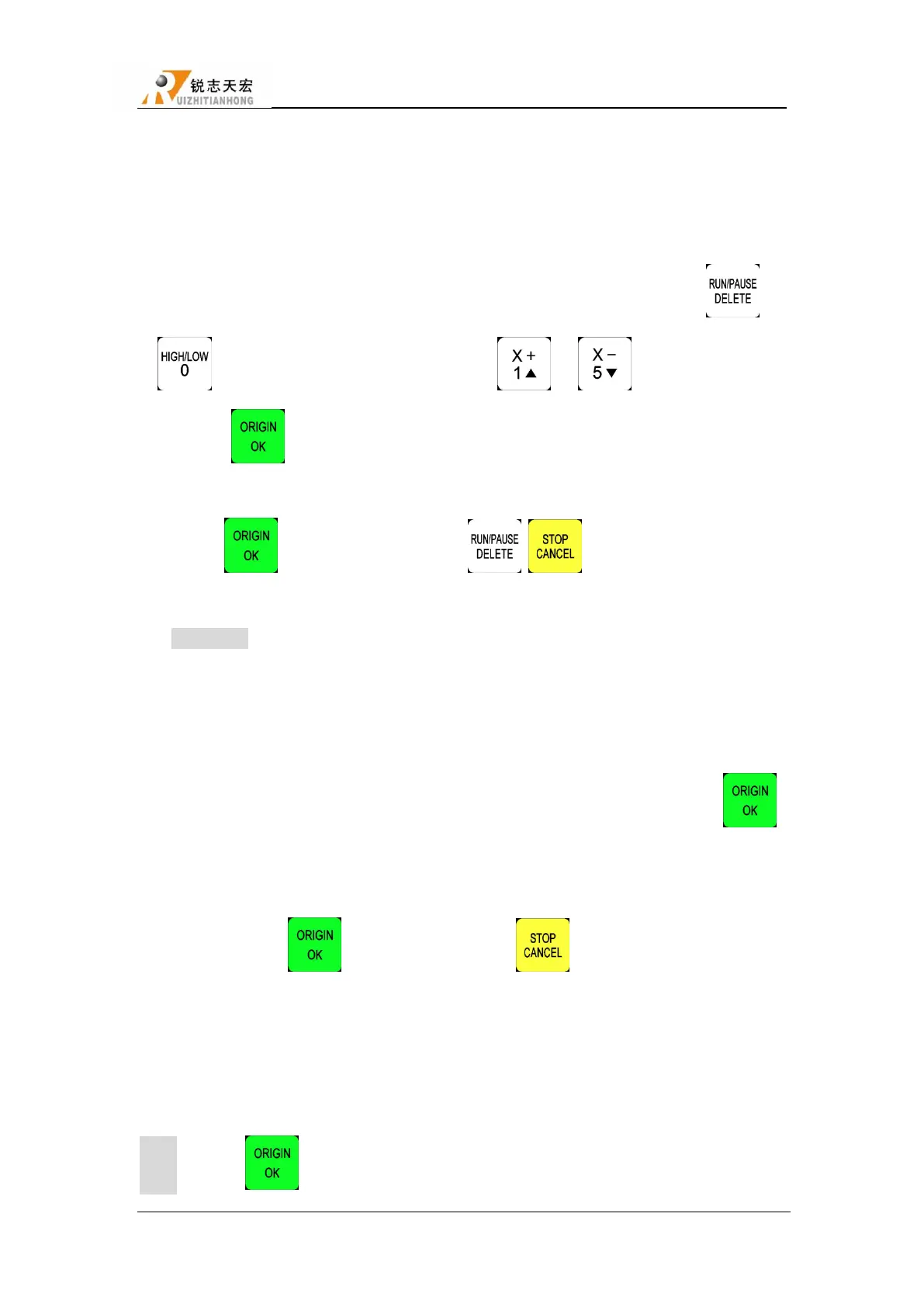

users can choose this operation. Move X,Y axis to the processing stop position,press“ ”+

“ ”to start ―Advanced Work‖,and then press“ ”、“ ”to choose ―Find break

no.‖,press “ ”to get in,after reading,screen shows:Press enter key to continue working

from searching position,press other key only show the line number.

Press“ ”to start processing,press“ / ”,the screen will show theline

number.

CAUTION:Work coordinate system must be same to the coordinate system which saves the

breakpoint.

Look for position line number. If accidentally cutter break and user hasn’t saved the break

point, reboot system and replace the cutter. After that, user can manually move X, Y axis to the

nearest point where the cutter was broken (recommend to move a little further), press ― ‖

enter into ―Find break no.‖, afterwards choose the previous processing file, the system will prompt

―searching current position‖. System will start processing after finished the searching, the system

will prompt ―press ― ‖start processing,press ― ‖ to view the current position of

line number‖.

5.6.9 Scale work

If the actual processing requires different sizes of the same file, you can select the scale work,

you need to enter an enlargement or reduction ratio for processing.

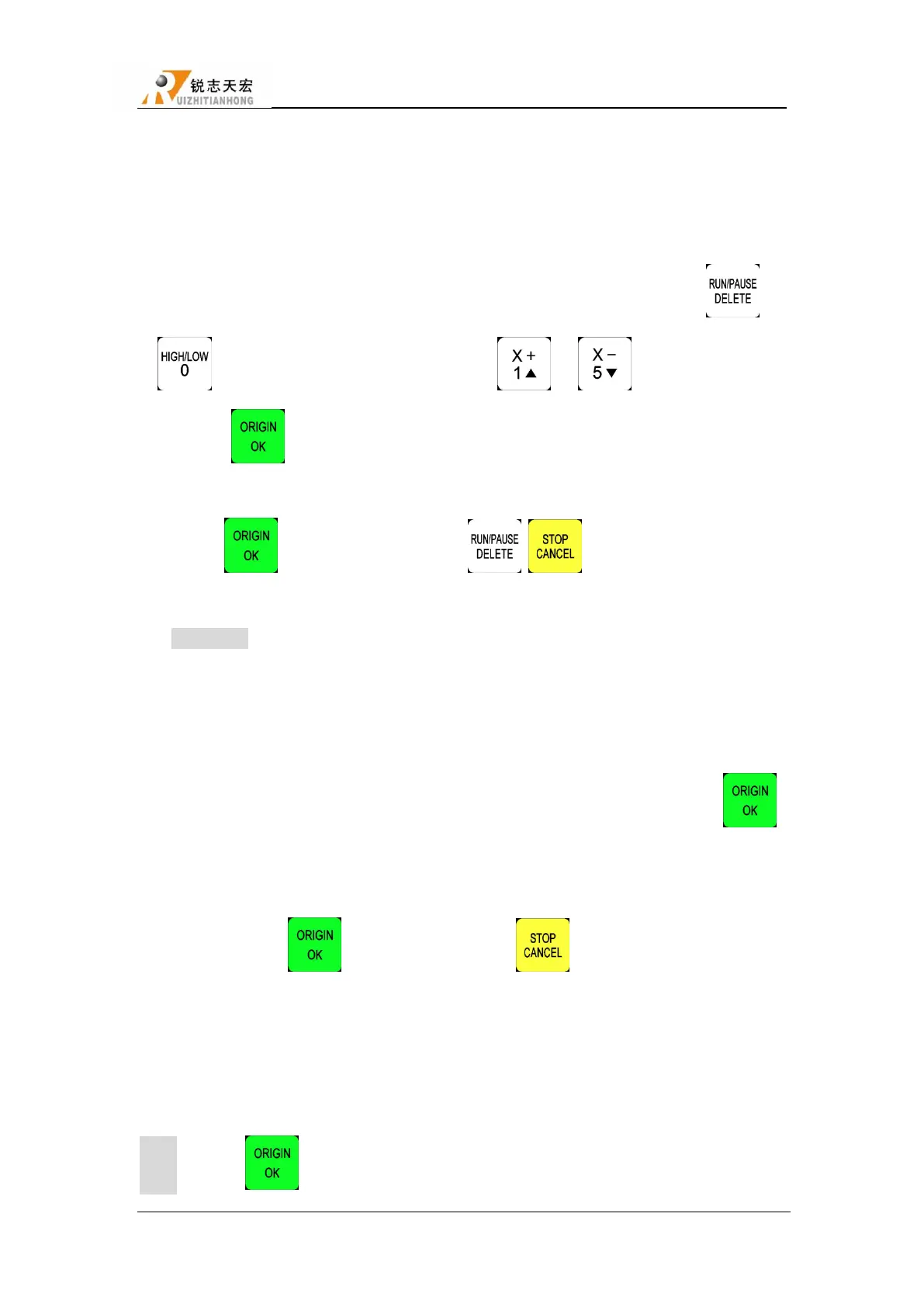

Steps:Press“ ”to get in “Scale work”:

Loading...

Loading...