Beijing RichAuto S&T Co., Ltd.

Forging ahead and determined to win 57

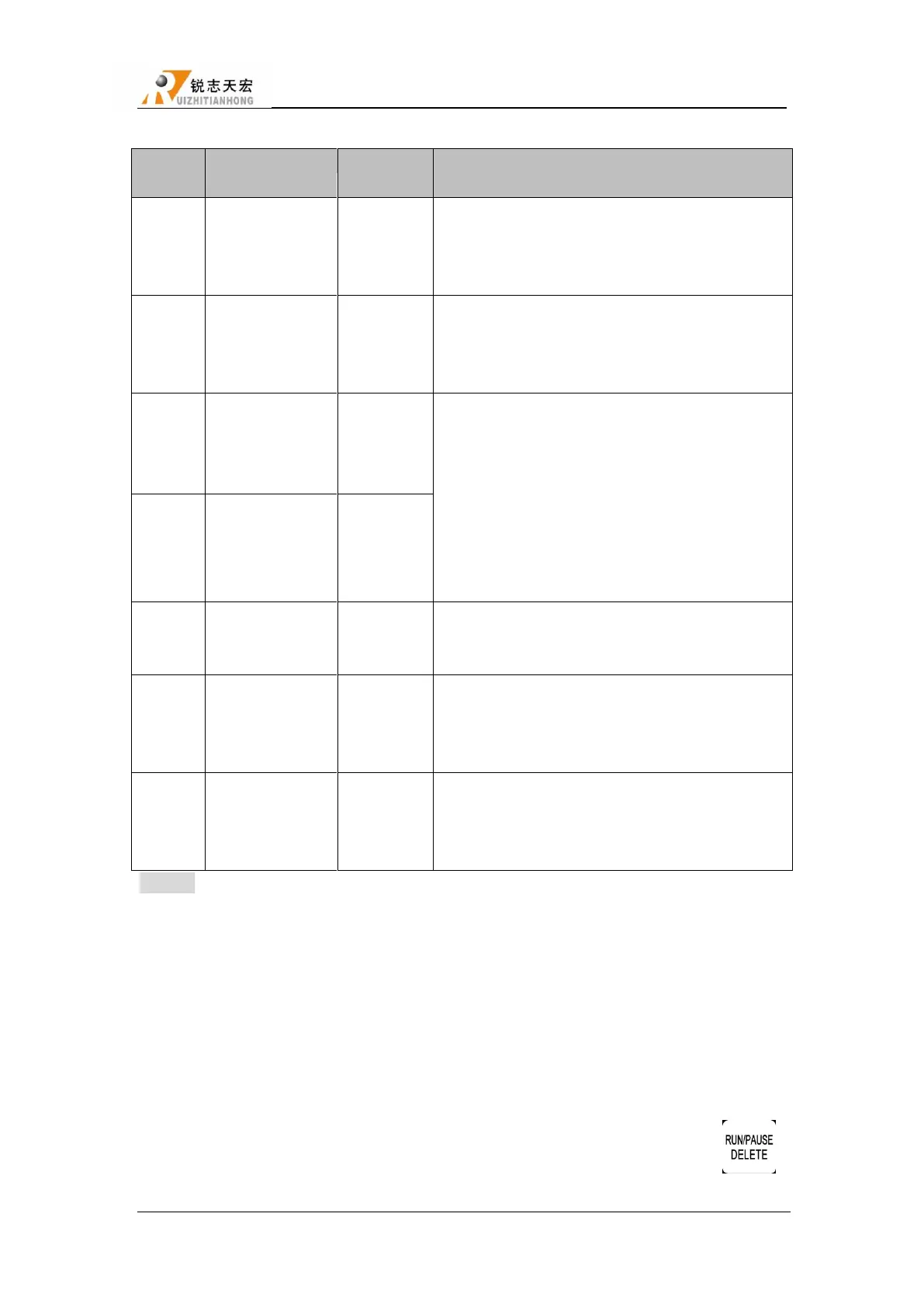

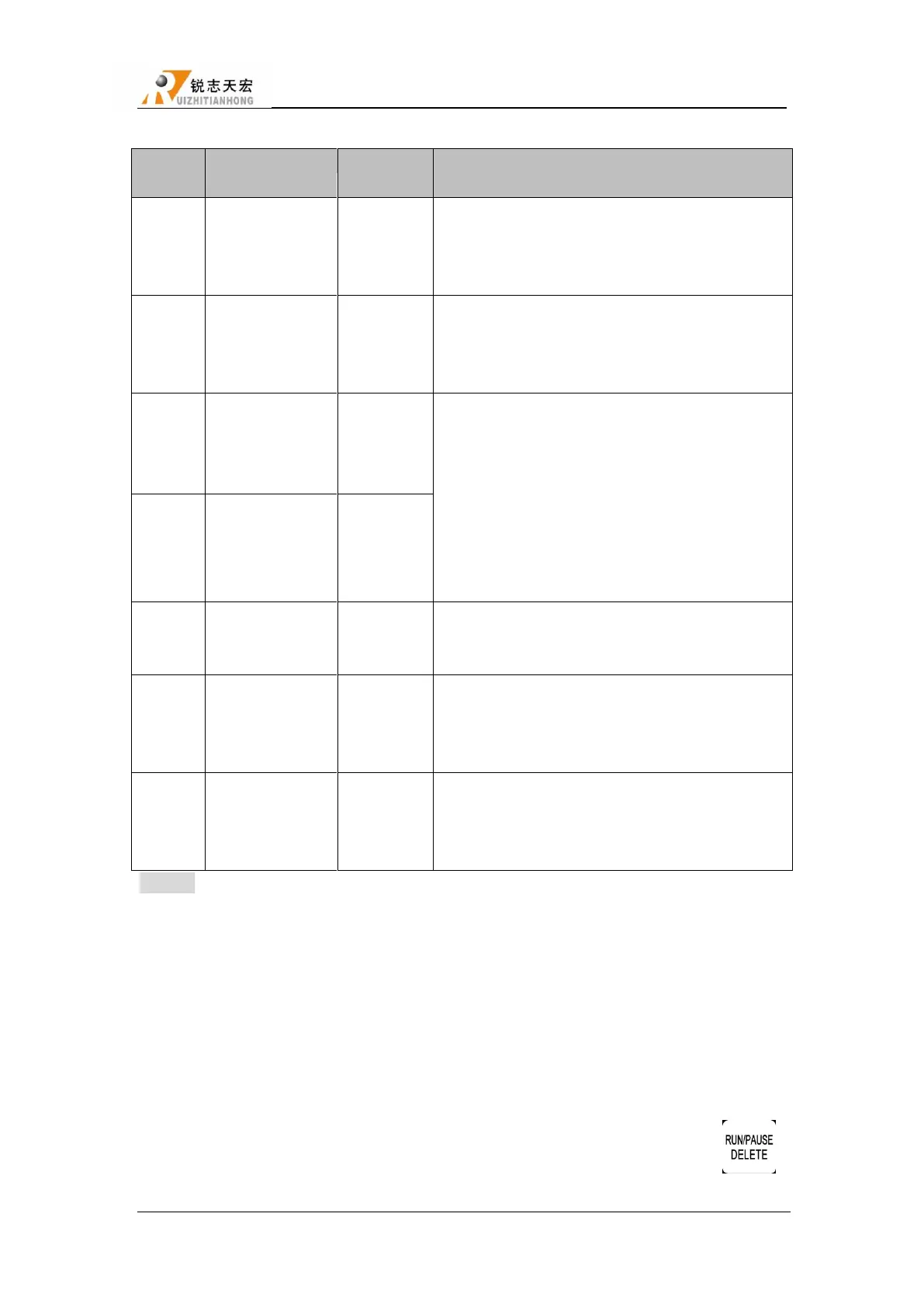

2. Parameter setting

Function

selection basic

switch 0

Bit 0:Set 0,positive rotation at positive rotation

command

Bit 1:Set 1,position control mode(pulse sequence

command)

Format seletion

switch of

position control

command

Bit 0 : Set 5,select the instruction mode as

―pulse+direction‖,negative logic

Electronic gear

ratio(numerator)

Pn20E=Encoder resolution

Pn210=Pulse equivalent×Screw pitch×Transmission

ratio

e.g. Pulse equivalent 1000,Screw pitch 10mm,

Encoder 20-bit,Transmission ratio 1

Pn20E/Pn210= 2

20

/1000×10×1=1048576/10000

=131072/625

Electronic gear

ratio(denominato

r)

Bit 1:Set 7,servo on all the time.

Bit 3:Set 8,positive rotation not used and signal

input(P-OT)prohibited

Output signal

selection 2

Set it when servo motor with brakes.

Bit 2:Set 3,brake interlock signal ―/BK‖is output

from CN1-29,CN1-30 to control 24V relay used for

brake

Output signal

selection 1

Set it when servo motor with brakes.

To avoid of CN1-29 and CN1-30 being used for

other function and leading to brake ineffective,3 is

not allowed to appear in the 4 digits.

NOTES:

1.

The same below.

2. For parameters which No. have a suffix of "*", changed contents will be validated when you

turn on the control power. The same below.

3. ALM+: pin-31,ALM-: pin-32,normally closed. The default alarm input terminal of

A11,A12,A15 is X5,A18 is X6.

Machine Setup-Voltage Setup,modify level of X5(X6-A18) normally closed(Press“ ”

Loading...

Loading...