ORBIT 16

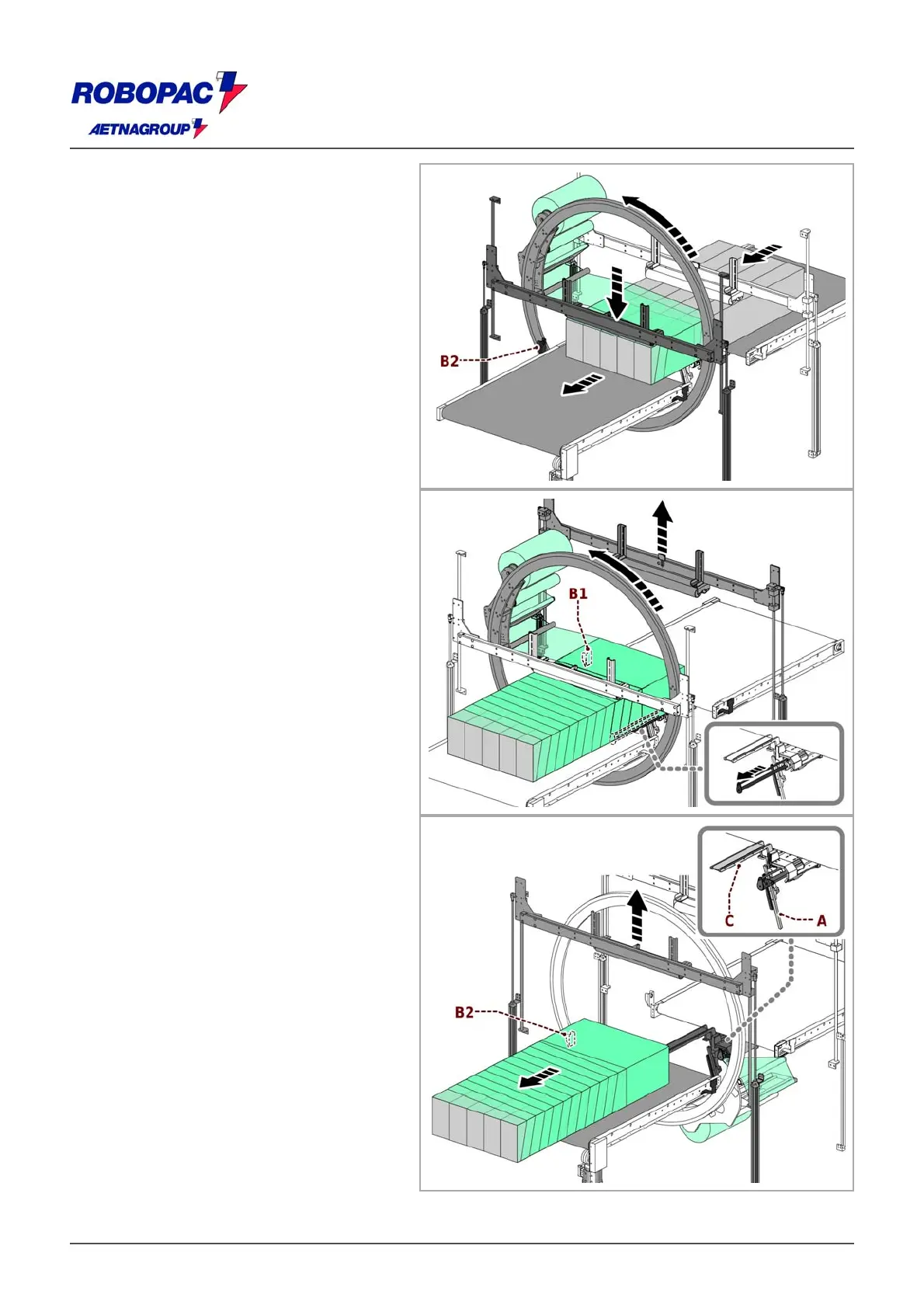

Phase 2

‒ When the “head and tail revolution”

count is completed, the conveyor

restarts and product length wrapping

begins.

‒ The product moves forward and engages

photocell (B2), the outfeed pressure

platen lowers on the product while the

machine continues to wrap product.

Note

The overlapping of film wraps is defined

by roller conveyor speed, thrust bearing

speed and film width.

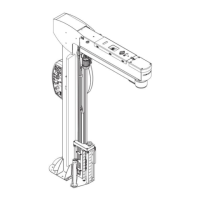

Phase 3

‒ The product moves forward disengaging

photocell (B1), the infeed pressure

platen lifts, the “tail positioning” timer

starts.

‒ After the timer count has finished, the

outfeed carrier stops, the “head and tail

turns” counter starts; the tail of the

product is wrapped and gripper comes

out at the last turn of the rotating ring to

grasp the coating.

Important

In case of 500 reel, the machine carries

out an additional pneumatic movement

to lock the coating inside the gripper in

the forward most position.

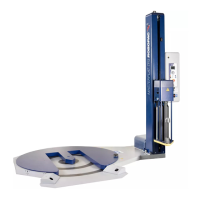

Phase 4

‒ After the “Head and tail turns” count has

finished, the rotating ring stops and the

pad (A) moves up, locking the film

against the stopper (C).

If there is a sealing unit installed, the

coating gets sealed as the pad moves

up.

The gripper returns to its position and

locks the coating.

‒ The blade comes out and cuts the

coating.

‒ The pad (A) lowers into rest position and

the blade is withdrawn at the same time.

‒ The outfeed conveyor restarts.

‒ The product detects the photocell (B2),

the outfeed pressure unit lifts up and the

“conveyor outfeed” timer starts.

‒ When timer has finished counting, the

conveyor stops and the products totally

wrapped can be removed from the

machine.

Loading...

Loading...