Rockwell Automation Publication 20P-TG002B-EN-P - February 2018 15

Component Test Procedures Chapter 2

Visual Component Inspection

Visually inspect the circuit boards and power components before energizing

the drive for any of the component test procedures.

1. Read the General Safety Precautions on page 10

.

2. Remove power from the drive (see page 42

).

3. Remove the protective covers (see page 43

) and lower the control EMI

shield (see page 58

) when necessary.

4. Check components for burn marks, breakage or foil delamination on all

circuit boards.

Replace any of these components without further testing if they show evidence

of burn marks, breakage, or foil delamination.

Troubleshoot a Control

Power Supply Failure

If a drive Power Failure fault (F3) has occurred and the drive is inoperable via

the HIM or other means of control, compete the steps below to determine

where the control power failure has occurred.

1. Read the General Safety Precautions on page 10

.

2. Remove power from the drive (see page 42

).

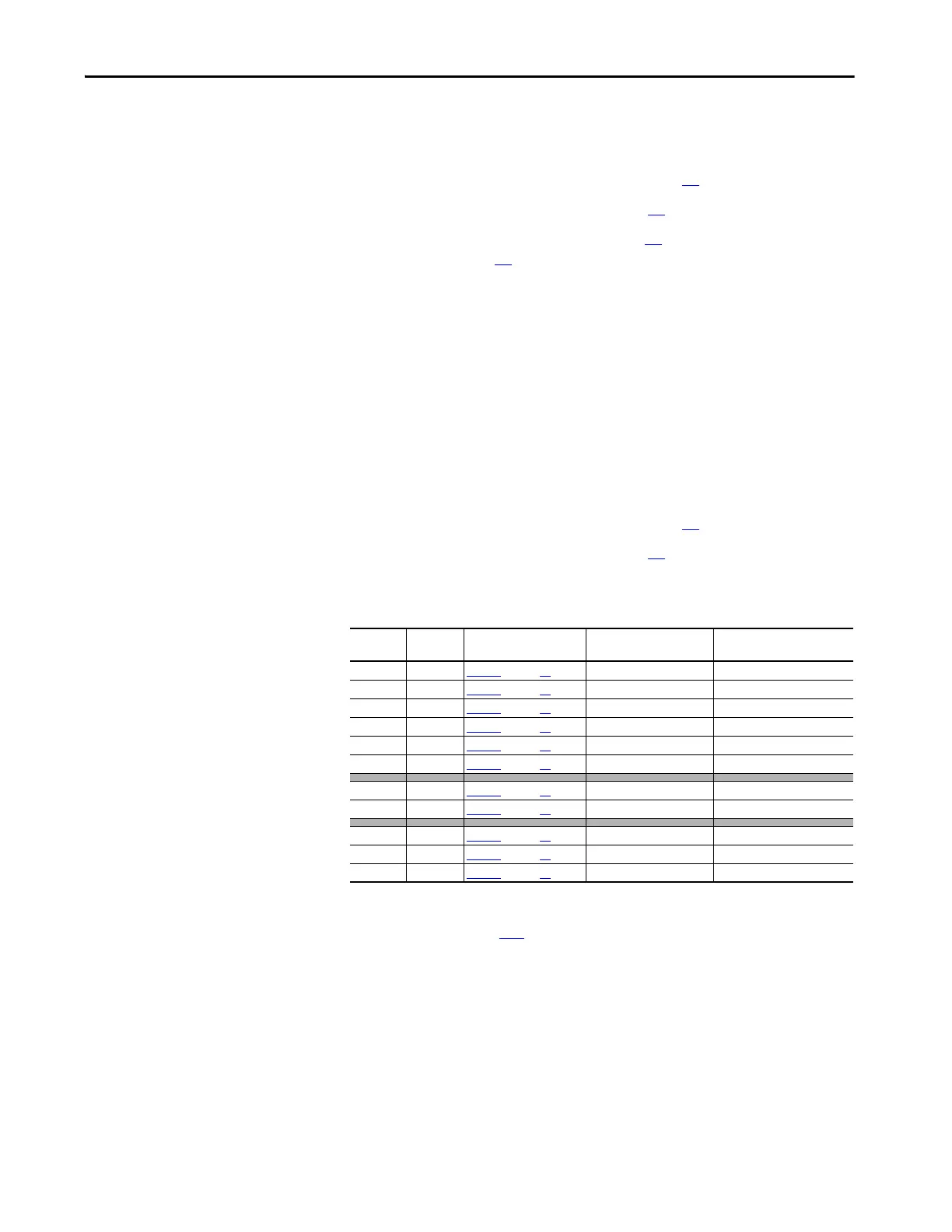

3. Measure the signal voltage at the testpoints on the control board as

indicated in the following table.

Note: For a flow chart version of the steps that follow, see Control Power

Supply Failure on page 122

.

4. If any of the signals in the table above is incorrect or missing, verify that

either 115V AC or 230V AC voltage is present at terminals U2 and V2

(control circuit power input).

• If the voltage is present and correct, continue with step 5 below.

• If the voltage is incorrect or missing, remove control power and verify

the wiring and power source to U2, V2 and correct any problems.

Test the voltage level again to verify that it is correct. If the voltage is

correct, but the drive is still inoperable, continue with step 5 below.

Name Testpoint For Testpoint Location

See…

Associated Connector-

Pin

Description

+ 5V XY5 Figure 1

on page 17 XA-1 / XA-3 / XA-5 +5V digital supply

GNDD XY6 Figure 1

on page 17 XA-2 / XA-4 / XA-6 +5V digital supply ground

GNDD XY7 Figure 2

on page 18 XA-2 / XA-4 / XA-6 +5V digital supply ground

+15V XY12 Figure 1

on page 17 XA-9 / XA-10 +15V analog supply

GNDA XY10 Figure 1

on page 17 XA-11 / XA-12 15V analog supply ground

-15 V XY11 Figure 1

on page 17 XA-13 / XA-14 -15V analog supply

+24V XY8 Figure 1 on page 17 XA-16 +24V terminal block

GNDV XY9 Figure 1

on page 17 XA-15 +24V terminal block ground

+5VEXP +5VEXP Figure 2 on page 18 XP3-1 / XP3-2 / XP3-3 +5V for DPI expansion

+12VEXP +12VEXP Figure 2

on page 18 XP3-4 / XP3-5 +12V for DPI expansion

0VEXP 0VEXP Figure 2

on page 18 XP3-7 / XP3-8 / XP3-9 DPI expansion ground

Loading...

Loading...