d04923.fm

INSTALLATION MANUAL

BRP-Powertrain

Effectivity: 912 Series

Edition 2/Rev. 0

73-00-00

page 18

August 01/2012

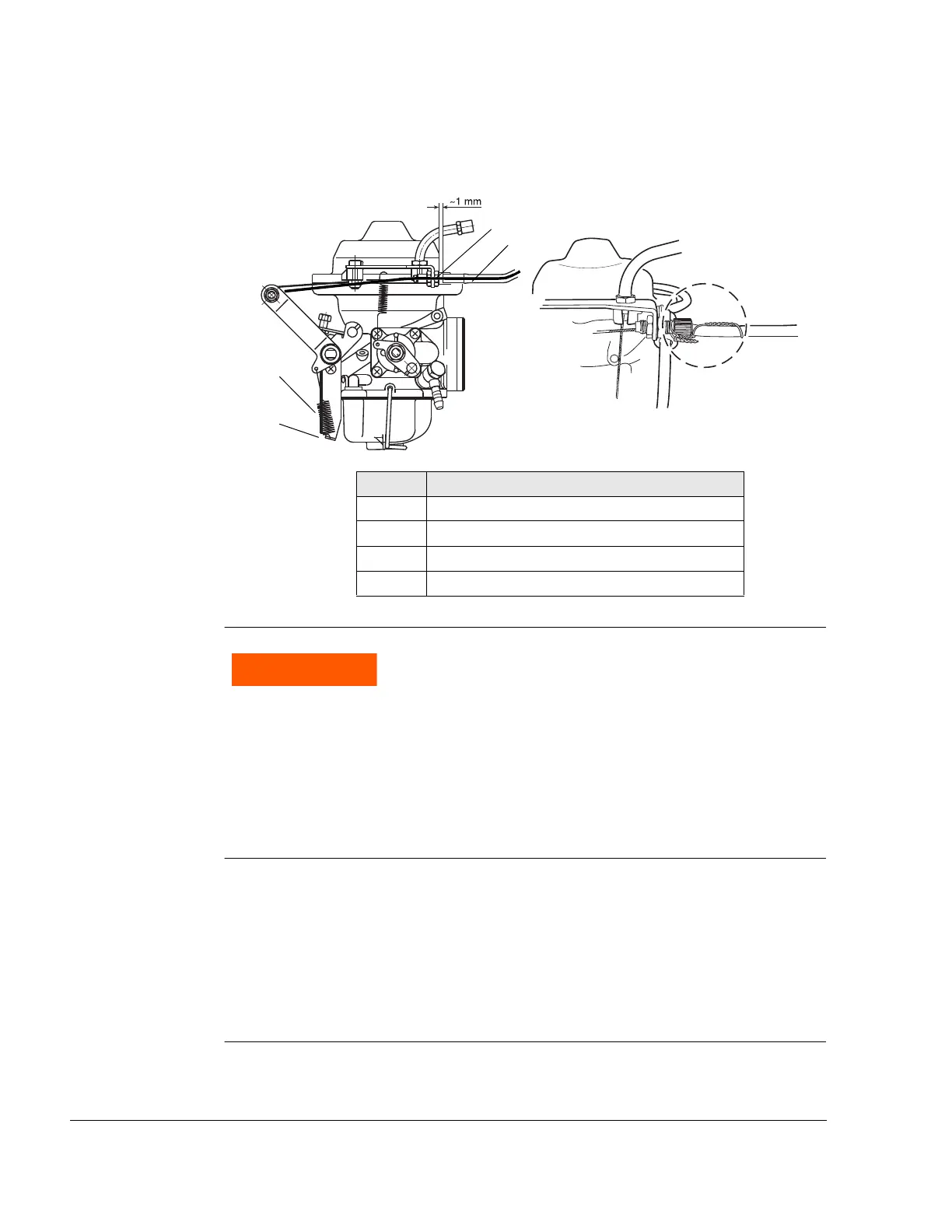

Graphic

Cable actuation

Fig. 10 08338,08354

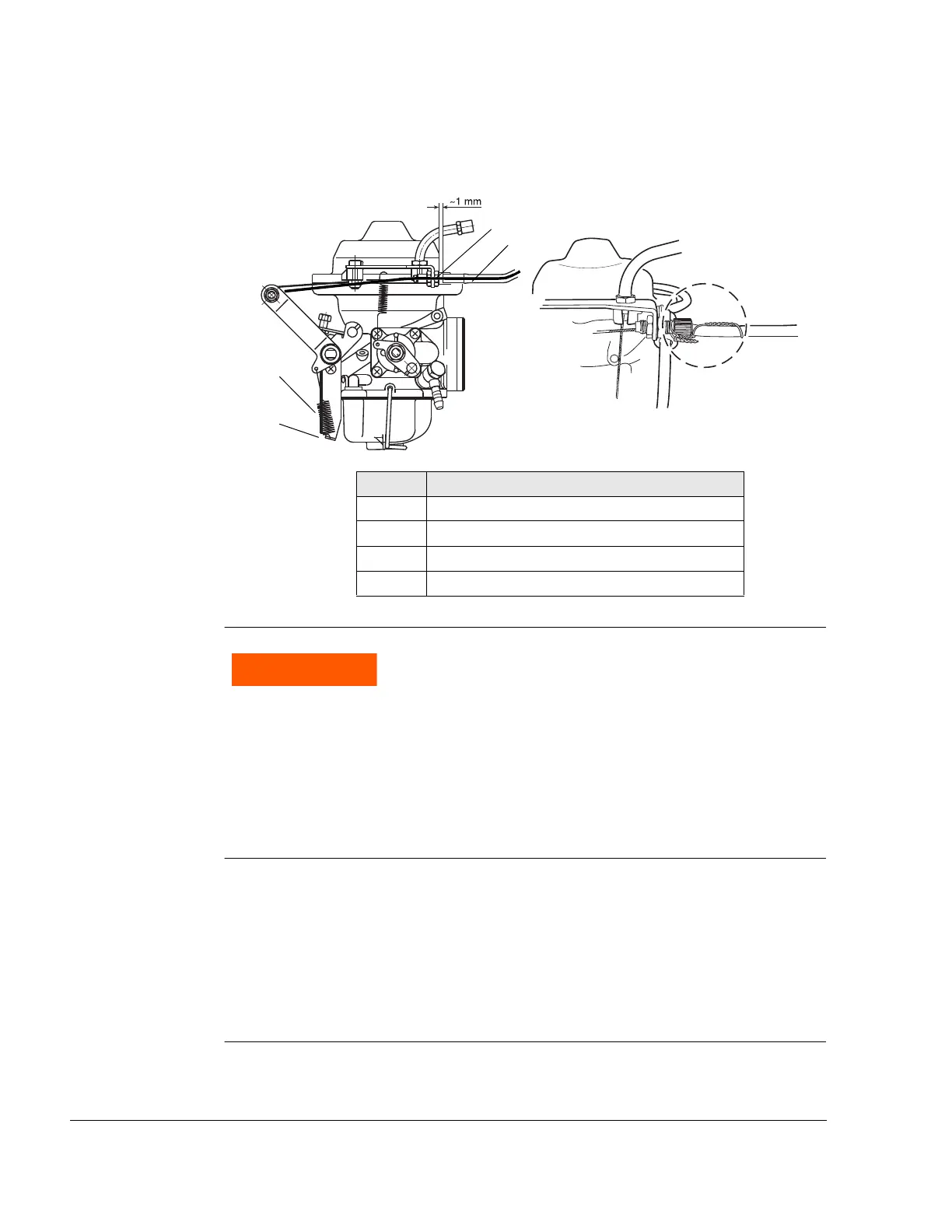

2.4) Requirements on the throttle lever

Mechanical stops See Fig. 11.

Adjustable positive stops for idle- and full throttle position are of course

required.

These stops have to be designed such to render adjustibility and to pre-

vent overload of the idle stop on the carburetor.

Part Function

1 Lever flap

2 Return spring

3 Cable sleeves

4 Adjustment screws

Adjust Bowden cable such that throttle and choke can

be fully opened and closed.

Use Bowden cable with minimized friction so that the

spring on the throttle can open the throttle completely.

Otherwise increase pretension of spring by bending

lever flap (1) or fit a stronger return spring, (2) or a

cable with pull-push action would have to be used.

Secure the bowden cable sleeves (3) in the adjustment

screws (4) (e.g. safety wire).

Loading...

Loading...