BRP-Rotax

MAINTENANCE MANUAL

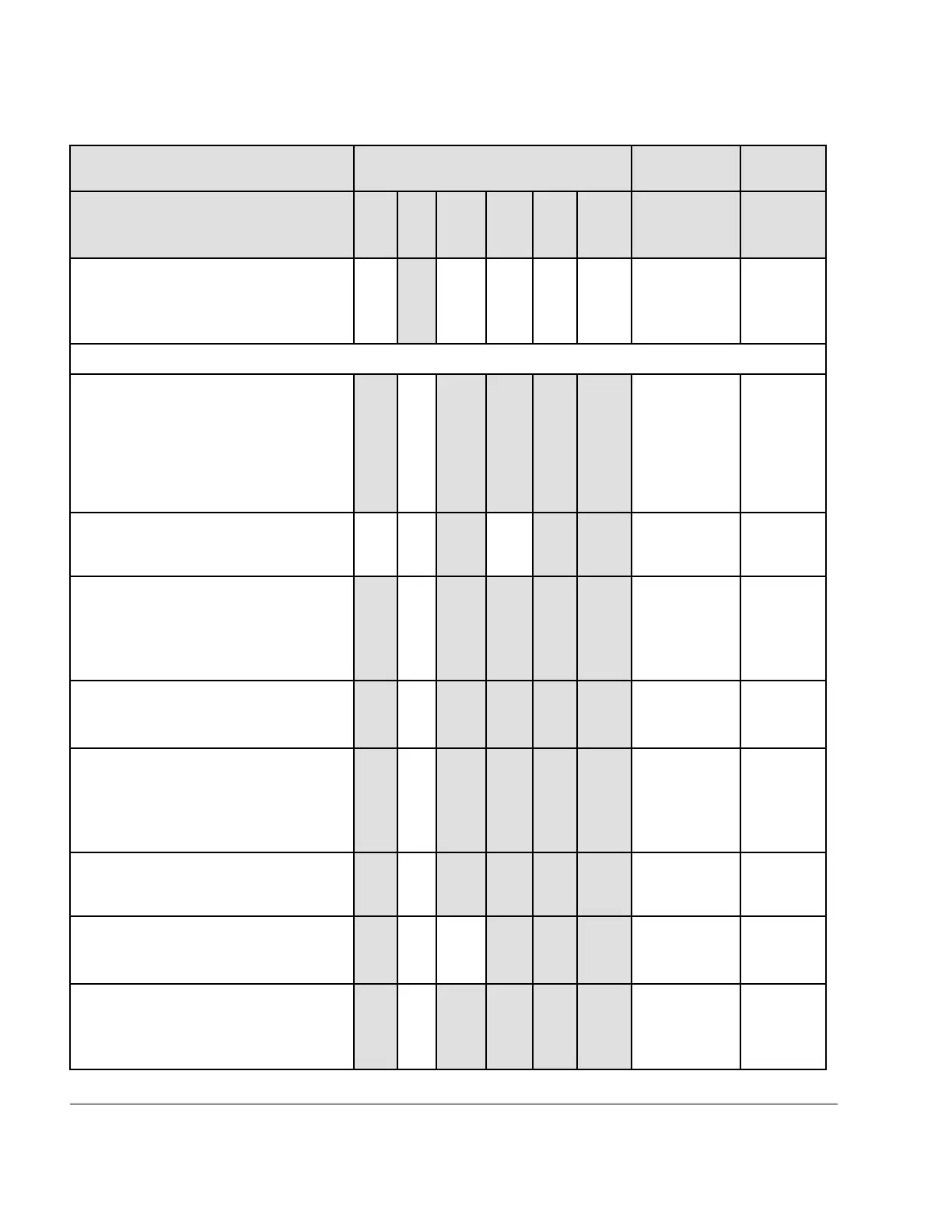

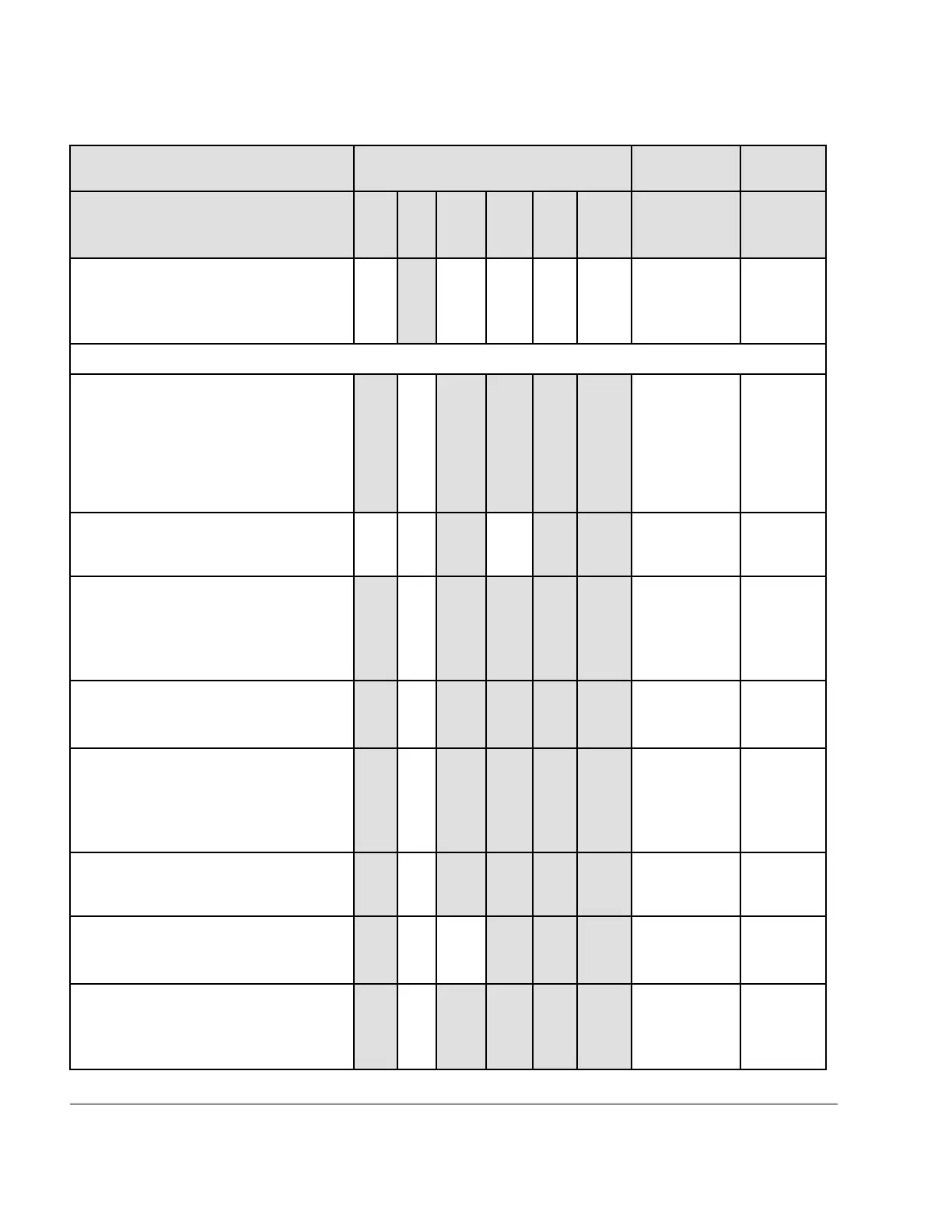

Points of Inspection

Interval Operating hours Chapter

Reference

Signa-

ture

* no periodic maintenance (require-

ment after the first 25 hours of

operation)

25* 50 100 200 600 1000

Positioning spring (large):

Findings:

______________________________-

______

X 12–20–00

Inspecting of

the oil filter

components

6) Visual inspection of the engine

General visual inspection of the engine

for damage or abnormalities. Check

cooling air duct and cooling fins of the

cylinders for obstruction, cracks, wear

and good condition. Take note of

changes caused by temperature

influence.

X X X X X 12–20–00

Visual

inspection

Inspect temperature sensors and oil

pressure sensor for secure fit and signs

of wear.

X X X

Inspect all coolant hoses of the engine

for damage, including leakage, harden-

ing from heat, porosity, loose connec-

tions and secure attachment. Verify

routing is free of kinks and restrictions.

X X X X X 12–20–00

Leakage

check

Carry out visual inspection of leakage

bore at the base of the water pump for

signs of leakage.

X X X X X 12–20–00

Leakage

check

Inspect the expansion tank for damage

and abnormalities. Check coolant level,

replenish as necessary. Inspect radia-

tor cap. Inspect protection rubber on

expansion tank base for correct fit.

X X X X X 12–20–00

Expansion

tank, radiator

cap

Check steel fuel rails for any cracks

and/or scuffing marks.

X X X X X 12–20–00

Checking the

fuel lines

Inspect the wiring (wiring harness) and

its connections for secure fit, damage

and signs of wear.

X X X X 12–20–00

Check of

wiring

Check the airbox (GENUINE ROTAX®

part) incl. throttle body actuation. In-

spect sensors for tight fit, damage from

heat, damage and signs of wear.

X X X X X

05–20–00

Page 10

December 01 2017

Effectivity: 915 i A Series

Edition 0/Rev. 0

Loading...

Loading...