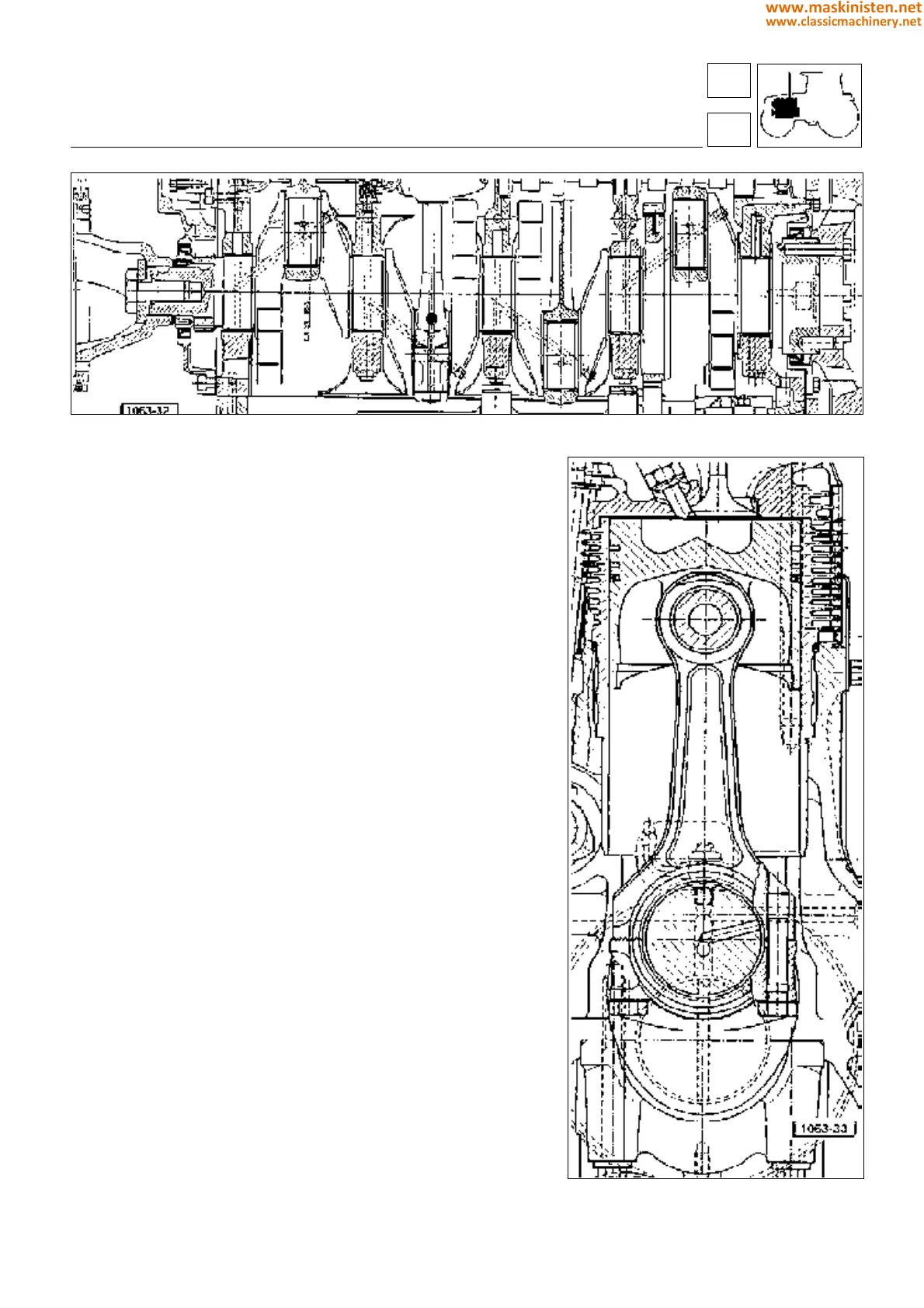

Fig. 11 - 4-cylinder engine crankshaft assemblcrankshaft

Crankshaft

The crankshaft is in nodular cast iron.

All operations must be carried out in compliance with the following

standards:

1 - Metalloscope inspection of 100% of pieces; cracks are not

permissible.

2 - When grinding the crankshaft, it should preferably rotate in the

opposite direction to its normal rotation in the engine, but rotation

in the same direction is permissible. During the polishing opera-

tion, however, the crankshaft must rotate only in the same direc-

tion as it normally rotates in the engine.

The surfaces must be polished and totally free of machining

marks.

NB: the permitted values for crankshaft grinding are given on page

29.

3 -The emerging Ø6 mm oilways must be chamfered with a radius

of 1.5 mm, and these chamfers must be free from machining

marks.

4 - Round off all sharp edges.

5 -The crankshaft (complete with ring gear, in the case of 4-cylin-

der engines) and Ø12 mm dowel, must be balanced both statically

and dynamically. The maximum permissible unbalance on the end

supports is 150 g cm.

6 - Before assembly, degrease and thoroughly clean the cranks-

haft, including the oilways.

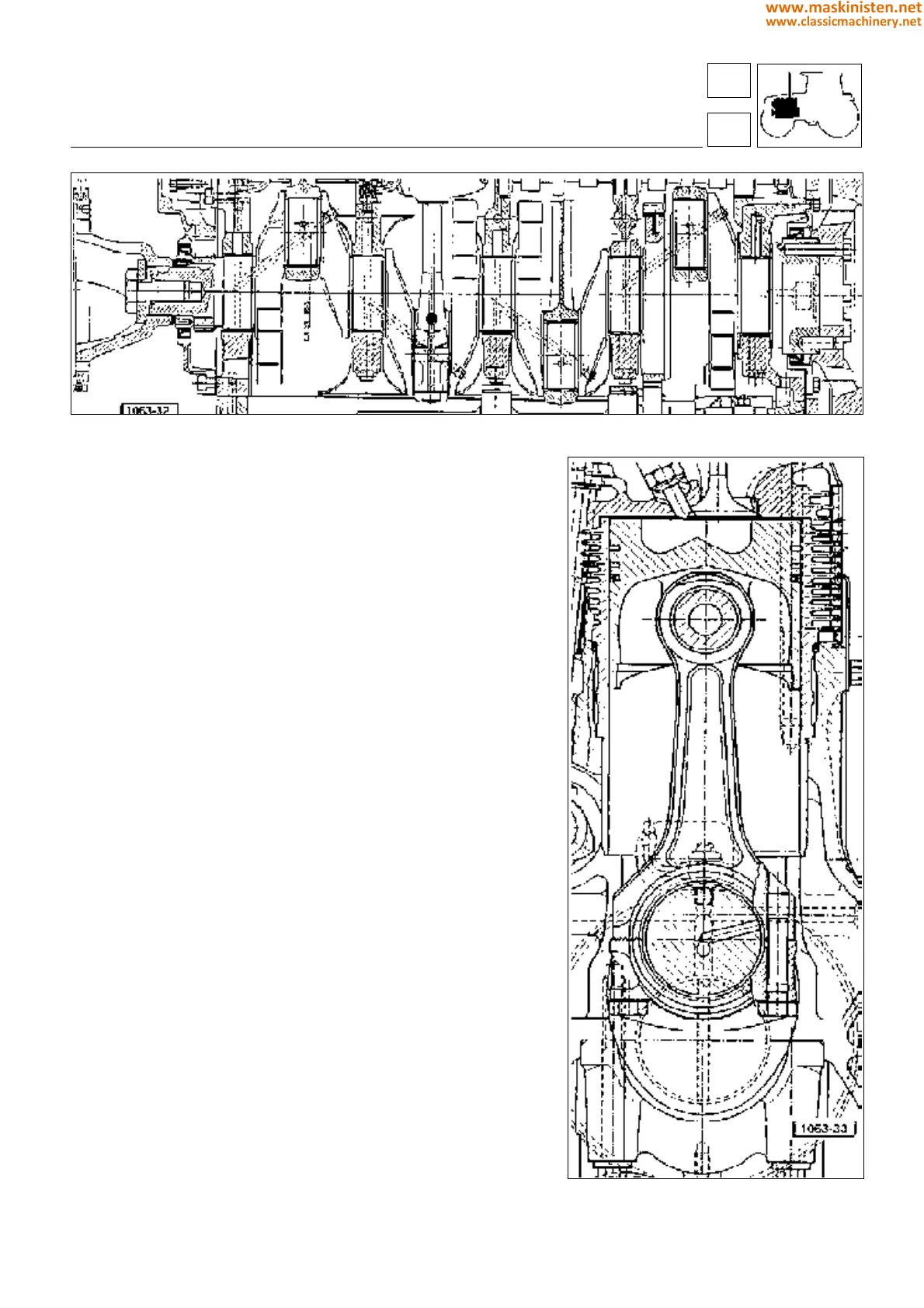

Fig. 12 - 4-cylinder engine crankshaft cross-sec-

tion.

engine

crankshaft

12

1

31

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...