Fig. 13 - Cleaning crankshaft lubricating holes.

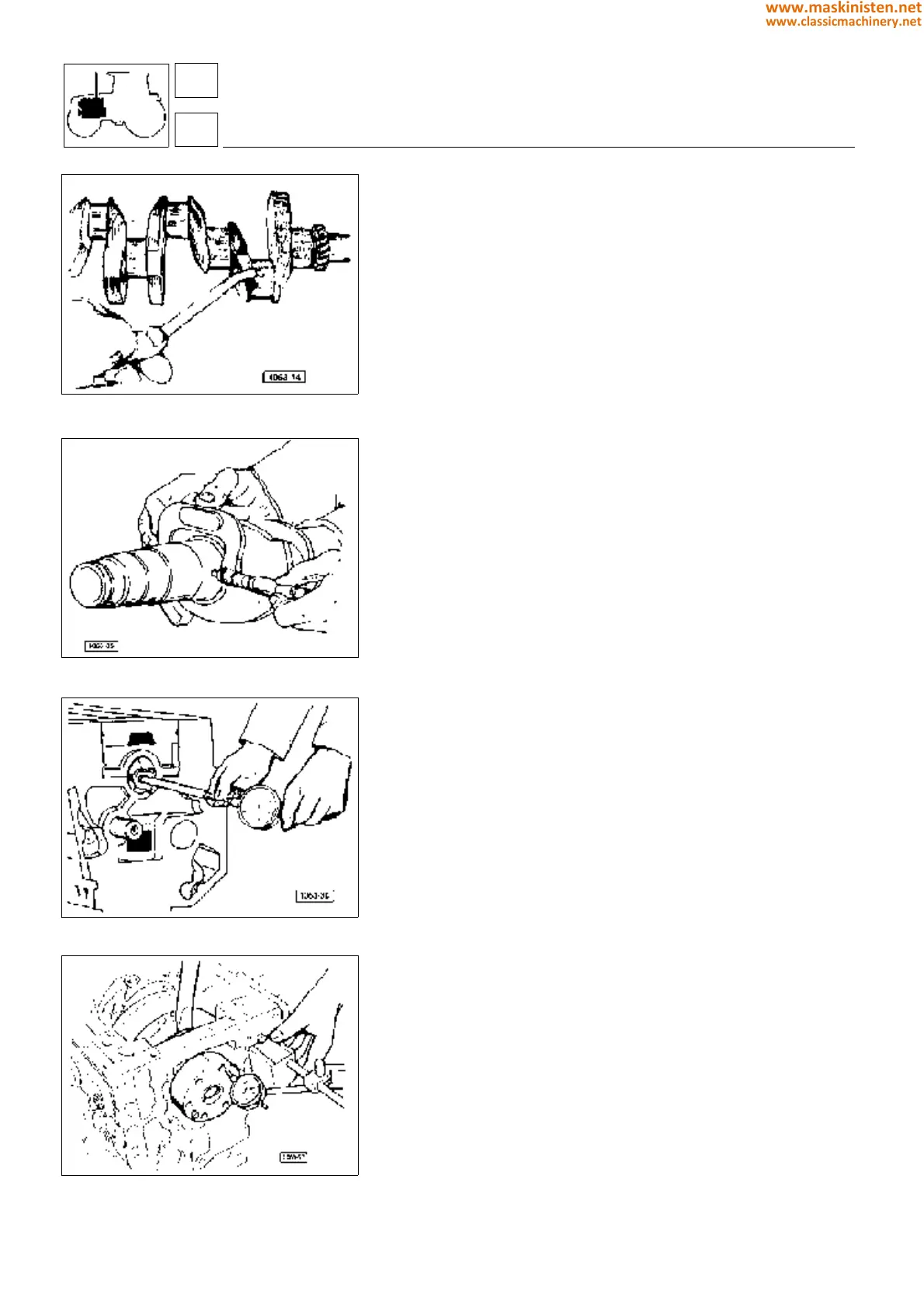

Fig. 14 - Checking crankshaft dimensions.

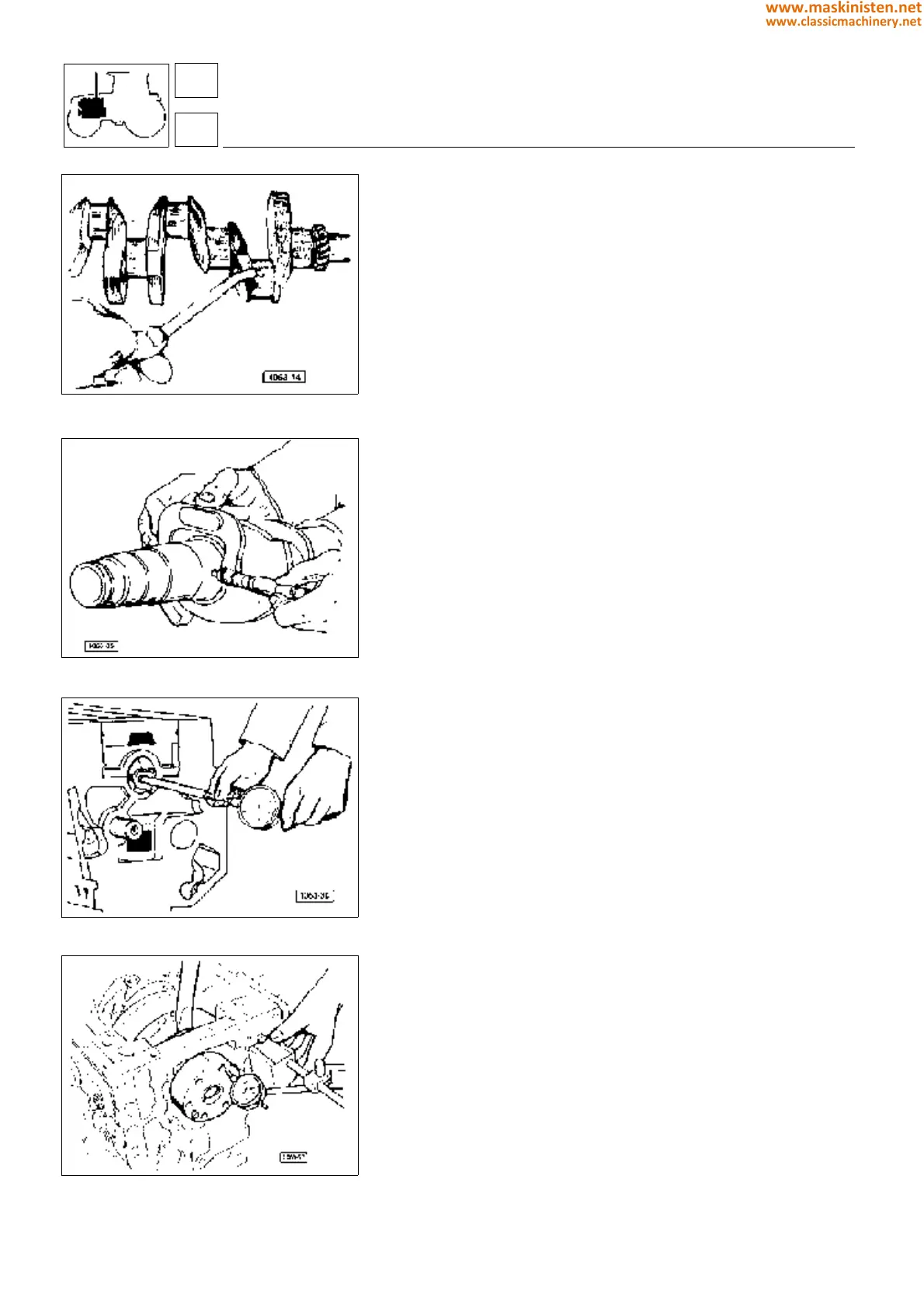

Fig. 15 - Checking main bearing inside diameter.

Fig. 16 - Checking crankshaft end play.

Crankshaft end play is adjusted by two-part spacer rings (see also

specifications table) fitted onto the rear main bearing sides (flywheel side);

these are provided with a projection preventing faulty assembly, the rings

can be mounted after crankshaft installation too.

Each main bearing consists of two shells each being provided with a small

tongue permitting it to be held in position inside the bearing cap seat. The

upper bearing shell is provided with a cavity for oil flow.

Main bearing caps shall be positioned according to the numbering printed

on their bodies and fixed to the block with two special securing screws,

which can only be replaced with other original screws.

Checking crankshaft

After the crankshaft has been thoroughly cleaned examine it carefully.

Meticulously ascertain the main and big end journals do not show signs

of seizure, otherwise rigrinding will be necessary. If the journals are

cracked the crankshaft shall be replaced.

Using a micrometer gauge make sure the main journal diameters are not

below the specifications given in the related table, otherwise a regrinding

should be performed.

Checking crankshaft journal out-of-roundness and

taper

With a micrometer gauge measure crankshaft journal taper and out-of-

roundness amounts; if readings exceed the maximum allowances speci-

fied a regrinding shall be performed. (Refer to specification table).

Checking main bearings

Clean main bearings carefully and then examine the internal surfaces for

indentation, scuffing, scratching or evident antifriction lining wear. If any

replace the main bearings.

Check main bearing inside diameters with an internal comparator. If the

diameters are found in excess of the maximum wear limits, the main

bearings shall be replaced.

Main bearings are supplied as spare parts either with normal size or

undersize inside diameters. The inside diameter undersize range is 0.25

to 0.50 mm.

Be very careful when installing the main bearings in order they can be

correctly positioned. The bearing shells provided with a lubricating hole

must be placed in the upper side (i.e. into the block forging and not into

the main bearing caps).

Mounting main bearing caps

The numbers stamped on the main bearing caps must be on the same

side as those stamped on the block.

Carefully check main bearing cap fixing screws for stretching, if so replace

them with original screws only.

The screws are to be tightened progessively to 1 kgm (9.8 Nm) torque

and subsequently to 3 kgm (30 Nm) torque then using no. 5.9030.640.0

tool furtherly tighten each single screw to an angle of 55°÷1’

engine

crankshaft

12

1

32

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...