Removal

The pump is secured to the tractor by 2 of the 4 bolts holding the

pump assembly together. These two bolts are diagonally opposite.

Having removed the pump from the vehicle, the components are

freed by unscrewing the two remaining bolts which keep the cover

A (see fig 3) clamped to the frame C and the pump body B; this

done, remove the washers and then the cover.

Using a proper pointed tool remove gasket E and then take the

bearings from their seats by pushing from inside outwards and

being careful the connecting pin neither be lost nor damaged.

Mark with a reference the position of the bearings with respect to

the pump case; then remove paying attention the connecting pin

neither be lost nor damaged.

Block the pump case in a vice as shown in figure and then remove

snap ring F.

Remove the seal ring.

WARNING - If pump bearings, pinions or casing are found to be

damaged or worn, these parts cannot be repaired because of their

construction tolerances.

When performing checks, in the warranty period, because of an

oil leakage or an excessive and irregular delivery pressure, only

the gaskets indicated in the spare parts lists can be replaced.

After checking the pump for wear due to abrasion from impurities

and for any other visible damage, when reassembling use, in any

case, a new set of gaskets.

It is also indispensable to mark each single part to reinstall

correctly.

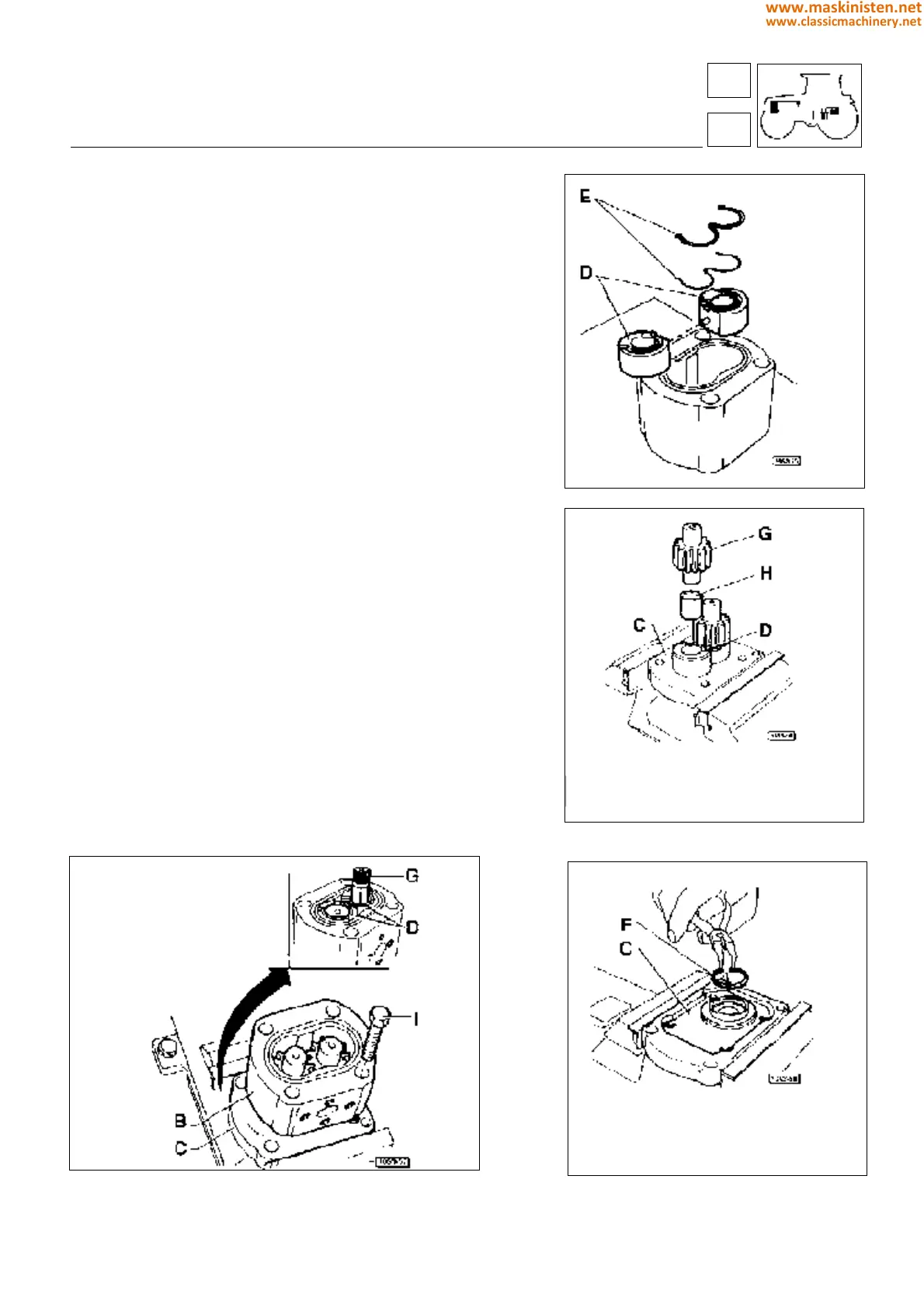

Fig. 5 - Pump disassembly.

Fig. 6 - Internal pump case parts.

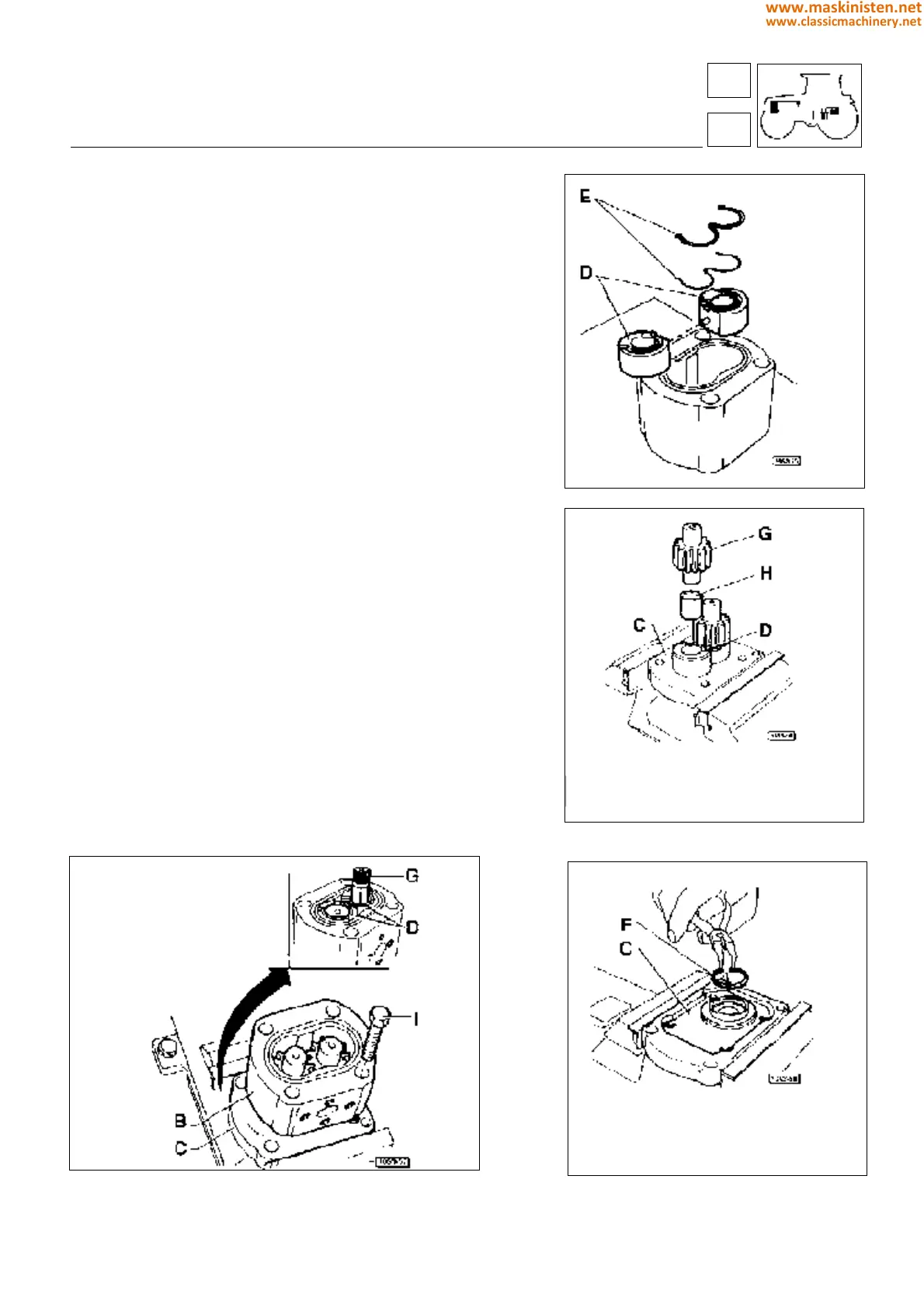

Fig. 7 - Pump gears.

Fig. 8 - Snep ring removal.

systems

hydraulic system

D - Bearing

E - Gasket

C - Housing

D - Bearing

G - Gear

H - Bush

C - Base

F - Snap ring

B - Pump case

C - Base

D - Bearings

G - Gears

I - Screw

82

8

379

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...