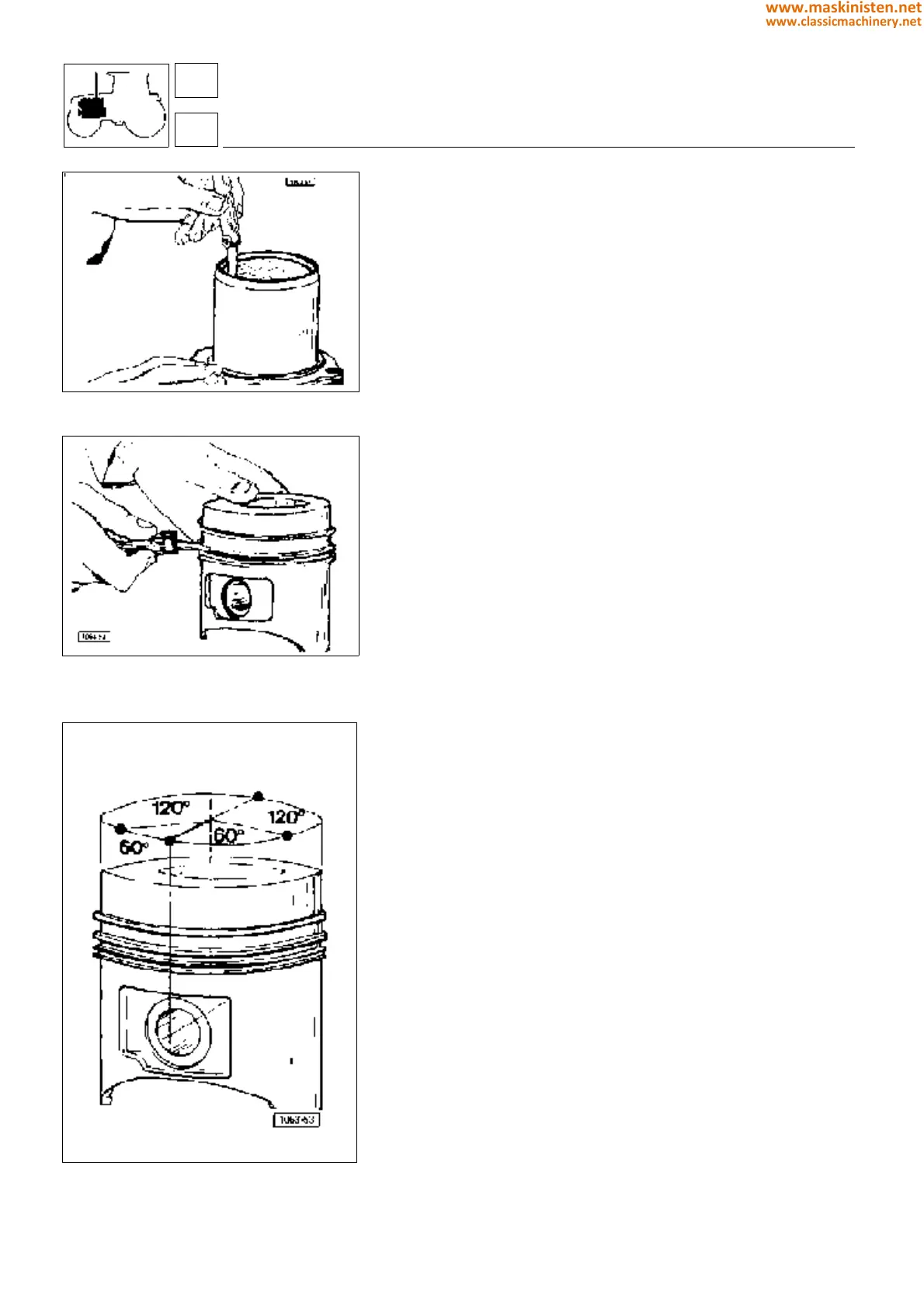

Fig. 31 - Checking piston ring end gap

Fig. 32 - Checking clearance between piston

rings and piston ring grooves in piston.

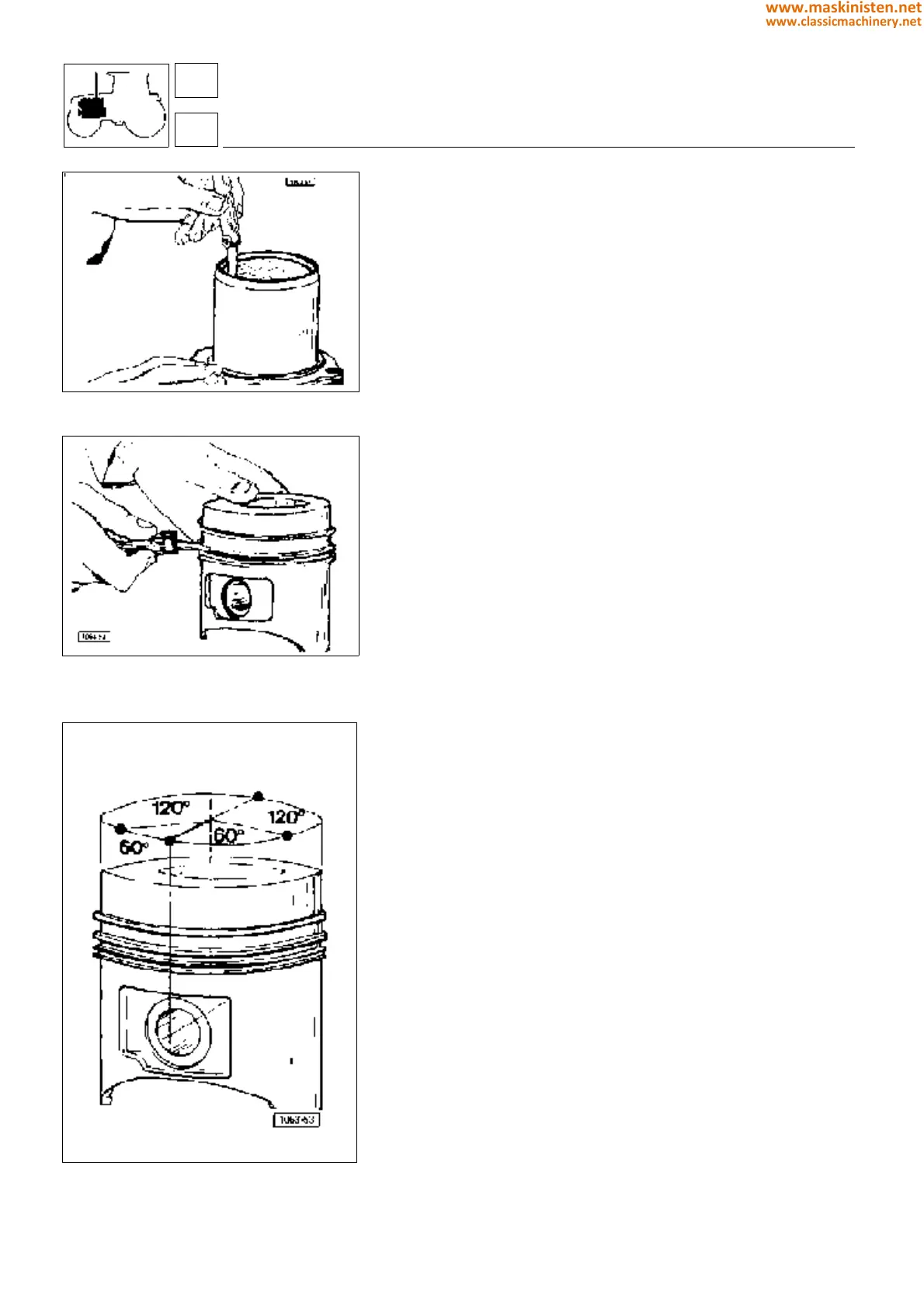

Fig. 33 - Correct assembly of piston rings.

Cleaning pistons

Descale piston crown and piston ring grooves using an emery

cloth.

Remove any buildups from gudgeon snap ring seats.

After all parts have been thoroughly cleaned and before further

checking is performed, examine them carefully for cracking or

damage which may require replacement.

Light scoring o seizing signs can be removed with very fine emery

cloth.

Checking pistons

Measure piston diameter with a micrometer gauge as shown in

figure 28.

If the diameter measured is below the specifications given in table

on page 35, the piston needs to be replaced.

Checking gudgeon pin and gudgeon pin seat in

piston

If either gudgeon or related seat diameter measurement differs

from specifications, the replacement of the worn-out part is recom-

mended.

Check also gudgeon pin snap rings for proper elasticity or da-

mage. If they are found not conforming to the operating conditions

replace them.

Checking piston ring end gap

Both the compression ring and the oil control ring ends installed

in the cylinder should not have a gap exceeding the specifications

shown in table.

This check is carried out by inserting the piston rings into the

cylinder so as the ring end gap can be measured with no.

5.9030.270.0 special thickness gauge, as shown in figure 31.

NOTE - Excessive clearance between piston rings and piston ring

grooves in piston may cause high lubricant consumption as well

as engine power loss.

Piston rings must be replaced each time piston is removed or

cylinders are replaced.

engine

crankshaft

12

1

38

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...