Checking clearance between piston rings and pis-

ton ring grooves in piston

This check is to be made with new piston rings, as shown in figure

32, by inserting the piston ring into the groove and then the blade

of no. 5.9030.270.0 thickness gauge. Refer to specifications table

for maximum clearance allowance.

If the clearance measured exceeds the maximum allowance,

piston shall be replaced.

Installing piston rings

During cylinder assembly perform a proper orientation of the first

piston ring so that its cut be moved by 60° from the gudgeon pin

axis.

The other piston rings should be inserted with their cuts moved by

120° from each other.

Installing pistons into cylinders

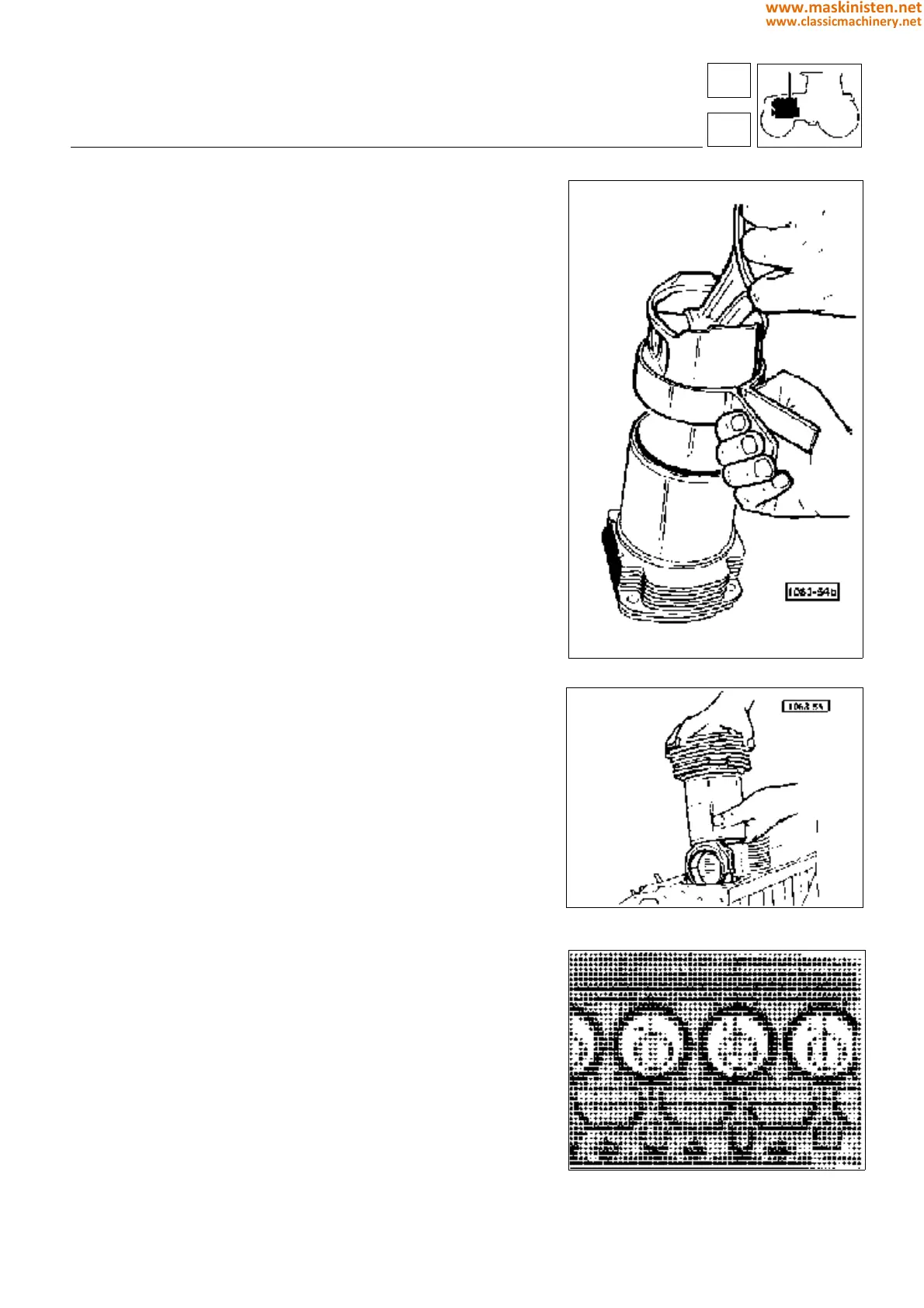

Use no. 5.9030.654.0 ring clamping band as shown in figure 34

to install piston into the cylinder.

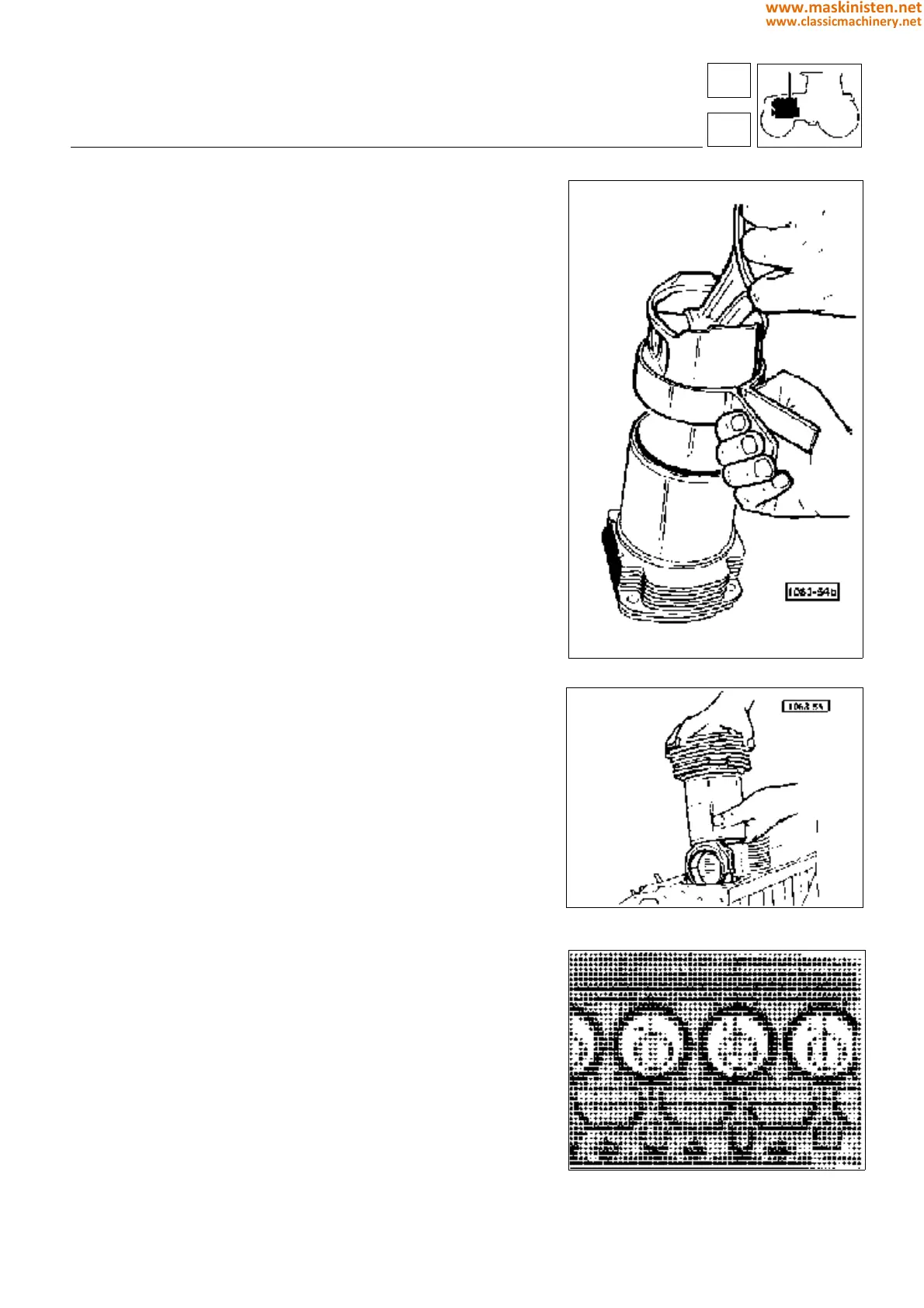

Afterwards insert piston and cylinder assemblies into the cylinder

block.

NOTE - Pistons can be taken without removing the crankshaft,

just withdrawing along with the connecting rods directly from the

cylinders after removing both cylinder heads and connecting rod

caps.

Before installing the cylinder liners, fit the O-ring seals code

2.1539.130.0.

The connecting rod-piston assembly must be assembled with the

piston crown recess oriented towards the tappets (Fig. 36).

The big-end caps must be fitted so that the punched number

appears on the same side as the number on the connecting rod.

Fig. 34 - Installing piston into cylinder.

Fig. 35 - Installing piston and cylinder assembly.

Fig. 36 - Correct orientation of piston and con-rod

assembly.

engine

crankshaft

12

1

39

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...