Cleaning cylinder heads

Clean the cylinder heads thoroughly by removing any coking

inside both exhaust and intake ducts. Also clean cylinder head

cooling fins carefully.

Checking valve seats

First descale and clean valve seats and then inspect for either

pitting or corrosion in the valve contact area, otherwise a new

grinding (if light wear is found) or a replacement shall be provided.

To install new valve seat inserts operate as follows:

chill the valve seat inserts in liquid nitrogen for easier installation

in the cylinder head by running fit.

Valve seat inserts are supplied as finished parts and do not require

any further machining. On installation avoid knocking on the valve

seats to prevent distortion.

NOTE - If no liquid nitrogen is available for valve seat insert chilling

before installation, it is also possible to heat up the cylinder head

to a temperature of 200° to 300°C.

Checking valves

Descale the valves with the special brush.

Make sure the valve seat is thoroughly intact, otherwise replace.

Check the valve stem for deformation, be sure the stem outside

diameter is not below specifications.

Testing valve tightness

After grinding the valve seats, test valve tightness as follows: plug

the intake and exhaust ports through the related valves and then

pour in some petrol and check for any leaks (if new valves are

installed a slight dripping is allowed).

Checking valve guides

Inspect valve guide boring inside surface. It should be thoroughly

smooth and show no evidence either of seizing or scoring.

Use no. 5.9030.020.0 gauge (fig. 17) for measuring the valve

guide inside diameter. Excessively worn guides are to be re-

placed.

When re-installing the valve guides they should protrude 14.5±0.2

mm from the seat in the cylinder head.

Using no. 5.9030.626.0 tool for installation will enable this dimen-

sion to be automatically obtained.

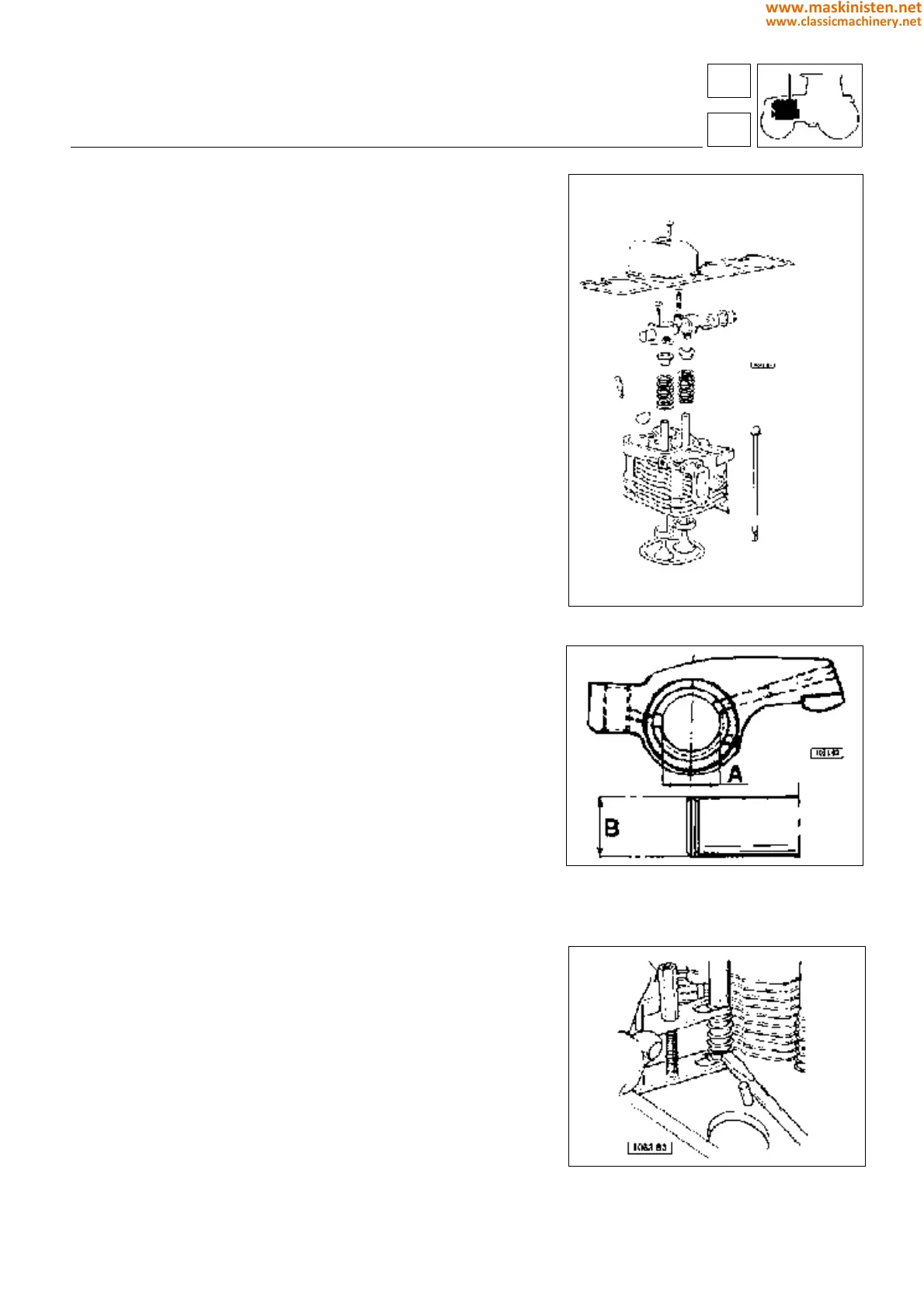

Fig. 9 - Cylinder heads, cylinders, valves and

rocker arms.

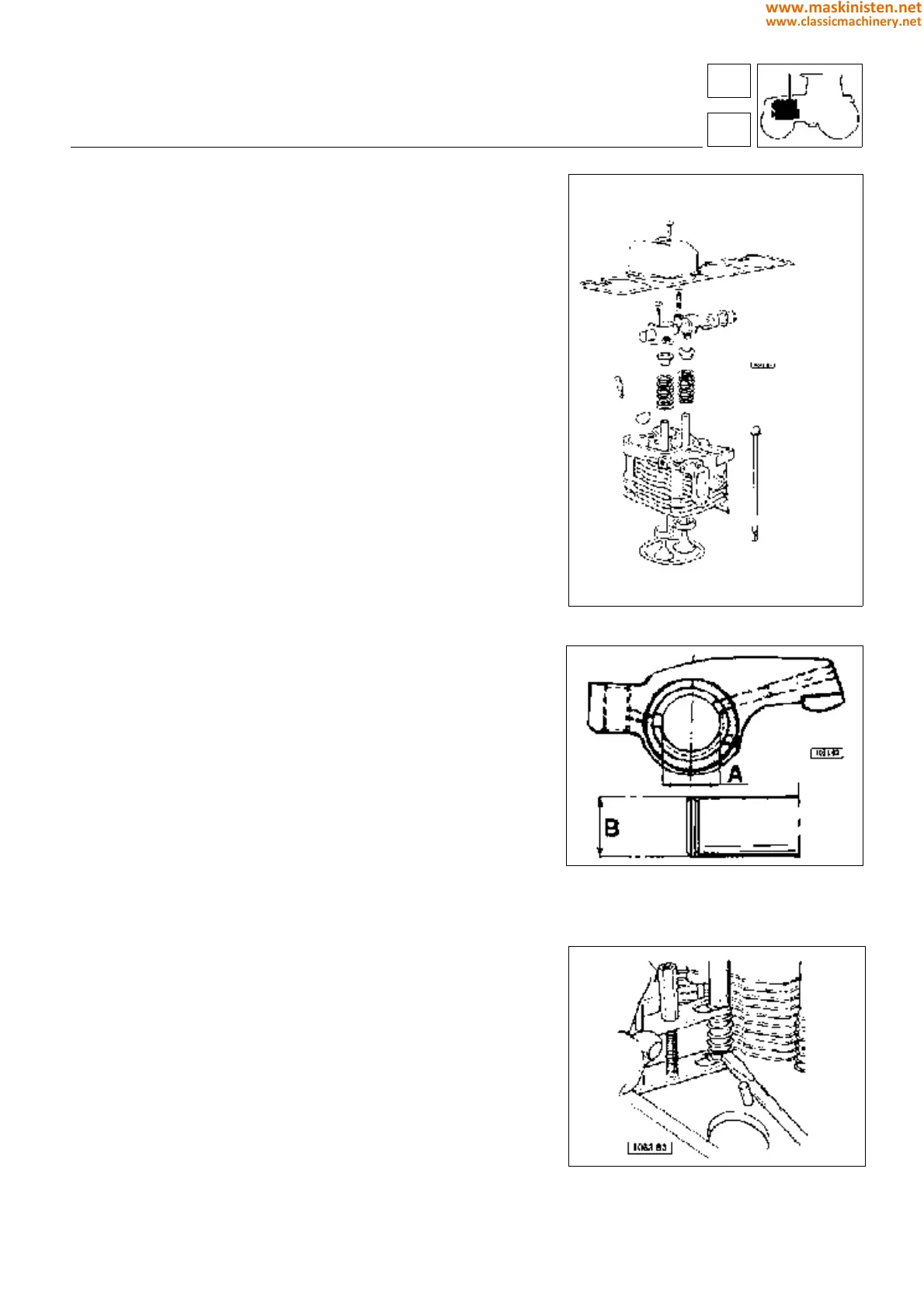

Fig. 10 - Bushing and rocker arm positions and

wear check dimensions.

A - Rocker arm bushing inside diameter

B - Rocker arm pin outside diameter

Fig. 11 - No. 5.9030.635.0 tool for tappet rod cap

removal.

engine

cylinder head

14

1

47

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...