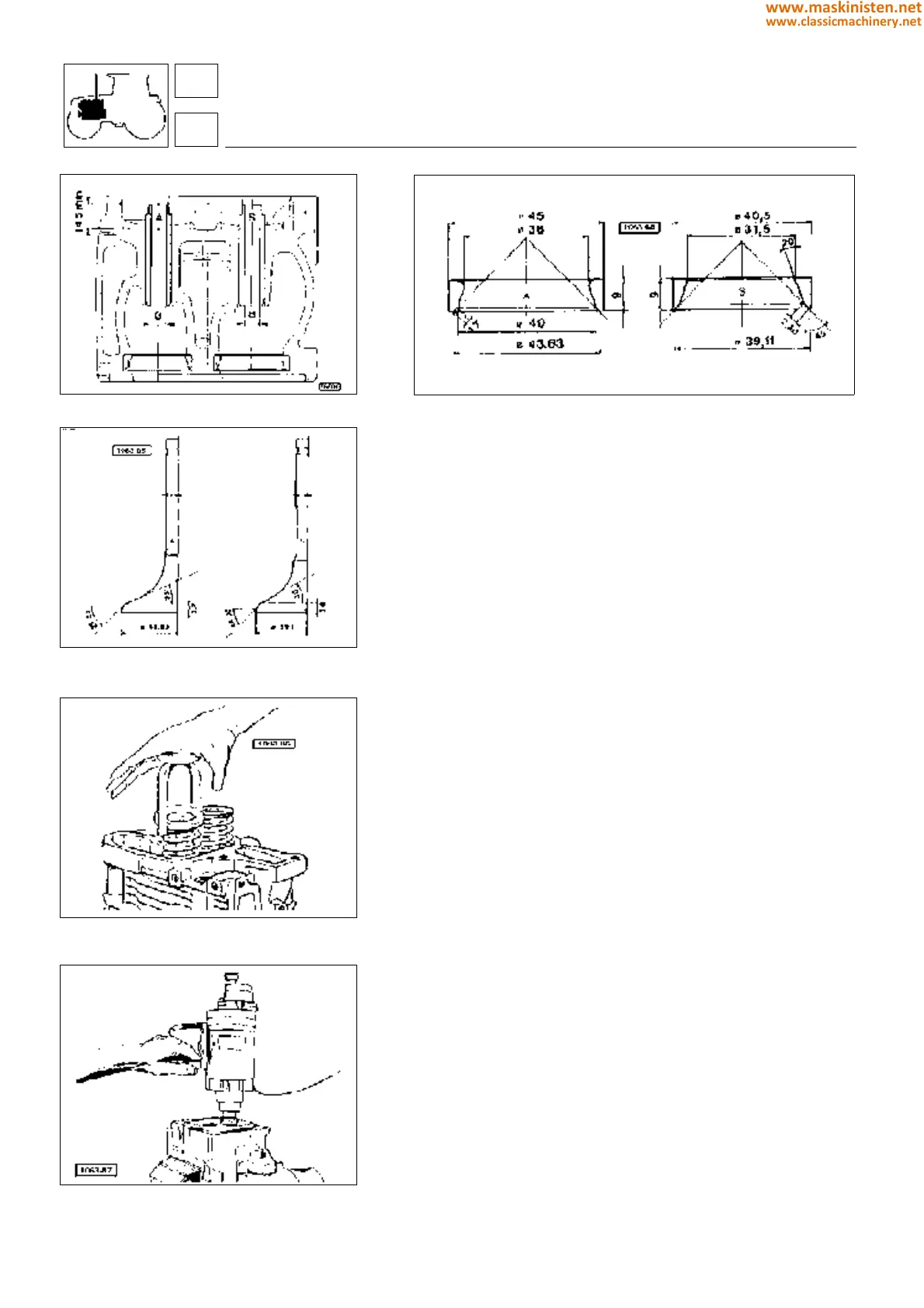

Fig. 12 - Valve seat inserts and valve guides.

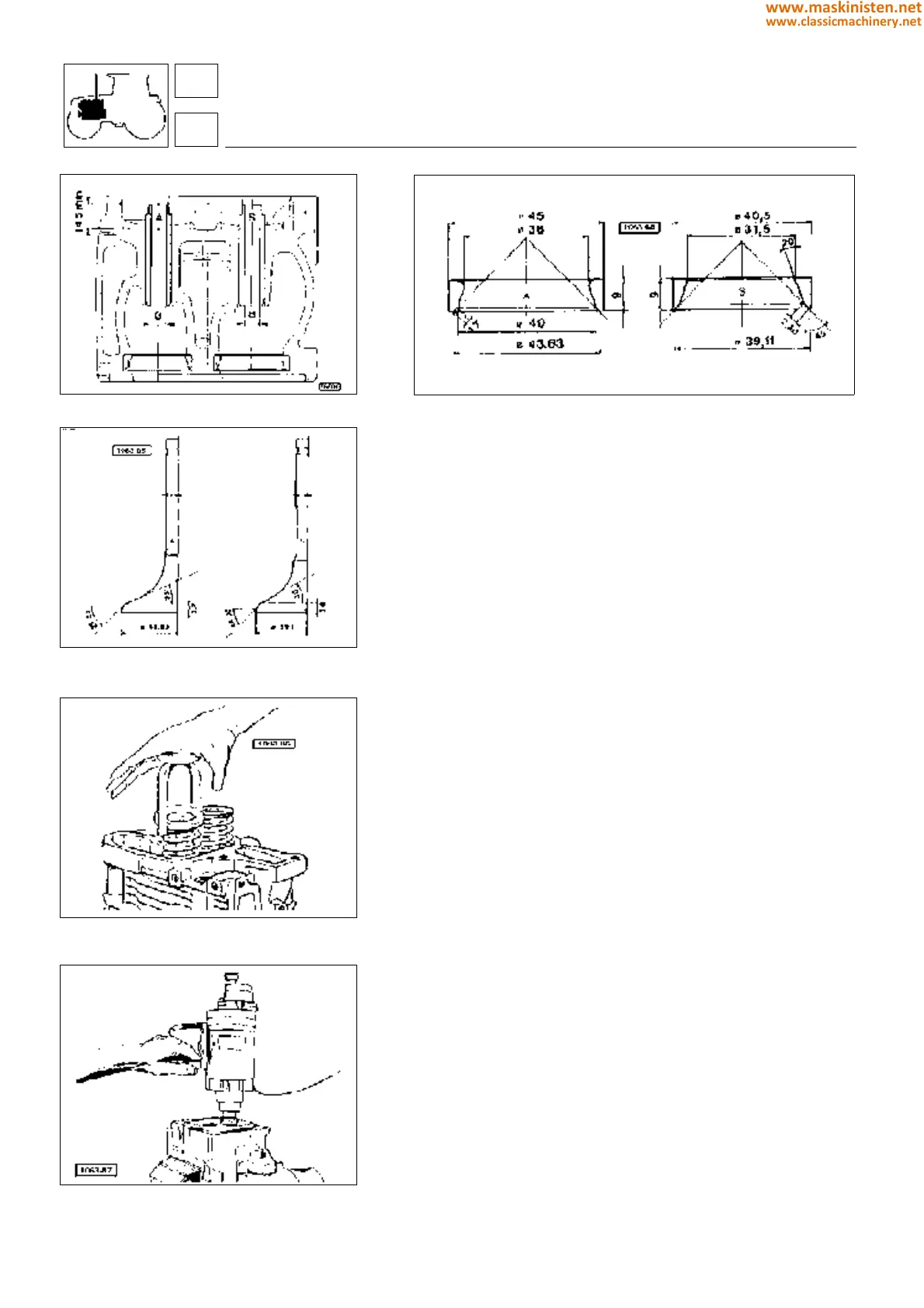

Fig. 14 - A - Intake valve

B - Exhaust valve.

Fig. 15 - Using no. 5.9030.012.0 tool to remove

valves.

Fig. 16 - Grinding valve seats.

Fig. 13 - Valve seat inserts.

Checking push rods

Examine rocker arm push rods for deformation and the rocker arm

contact ball seat for signs of seizing or roughness, if any, replace.

Make sure also the other push rod end in contact with the tappet

does not show excessive wear or nicks.

Checking valve springs

Make sure the valve springs have not lost their elasticity.

Also inspect valve springs for rust or damaged lacquering.

Checking rocker arms

Ensure the rocker arm working area is thoroughly smooth and no

nicks are shown.

Use a micrometer gauge to measure the rocker arm pin diameter;

reading should not be lower than specifications, otherwise re-

place.

Check the rocker arm bushing for excessive wear, replace as

necessary.

Check both rocker arms and valves for proper lubrication by

running the engine at idling speed, ensure the oil flow rate is

regular; should this not be the case the rocker arm bushing should

be inspected for proper installation or the ducts checked for

clogging.

Adjusting valve clearance

This adjustment is to be performed with a cold engine and piston

at T.D.C. at the end of the compression stroke (both rocker arms

shall be in uppermost position and detached from the valve

stems).

Rotate the crankshaft until the above mentioned conditions are

obtained, then use a thickness gauge to take clearance measure-

ment.

engine

cylinder head

14

1

48

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...