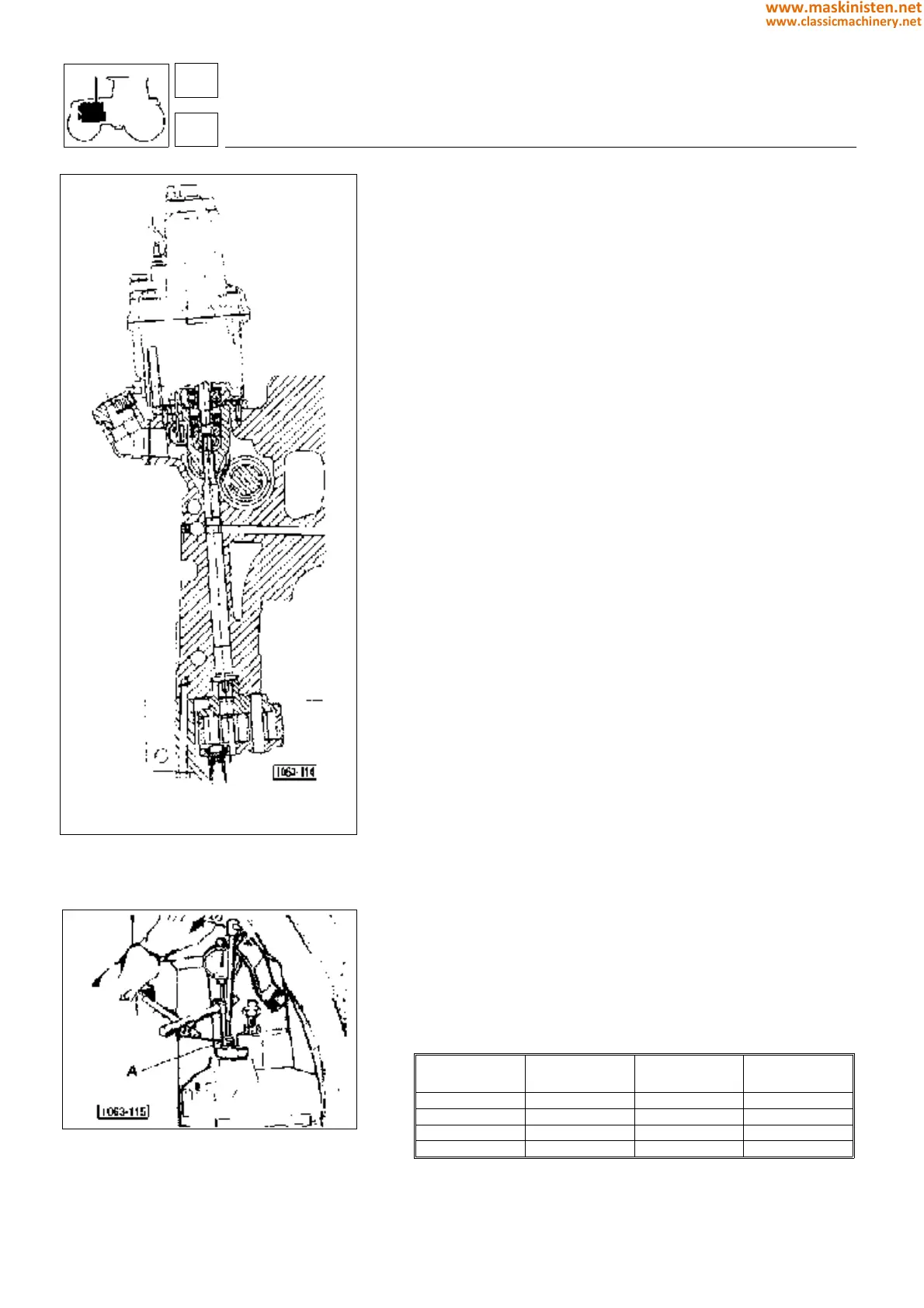

Fig. 15 - Engine-mounted governor unit.

(For engine 4-cylinders with governor mechani-

cal type).

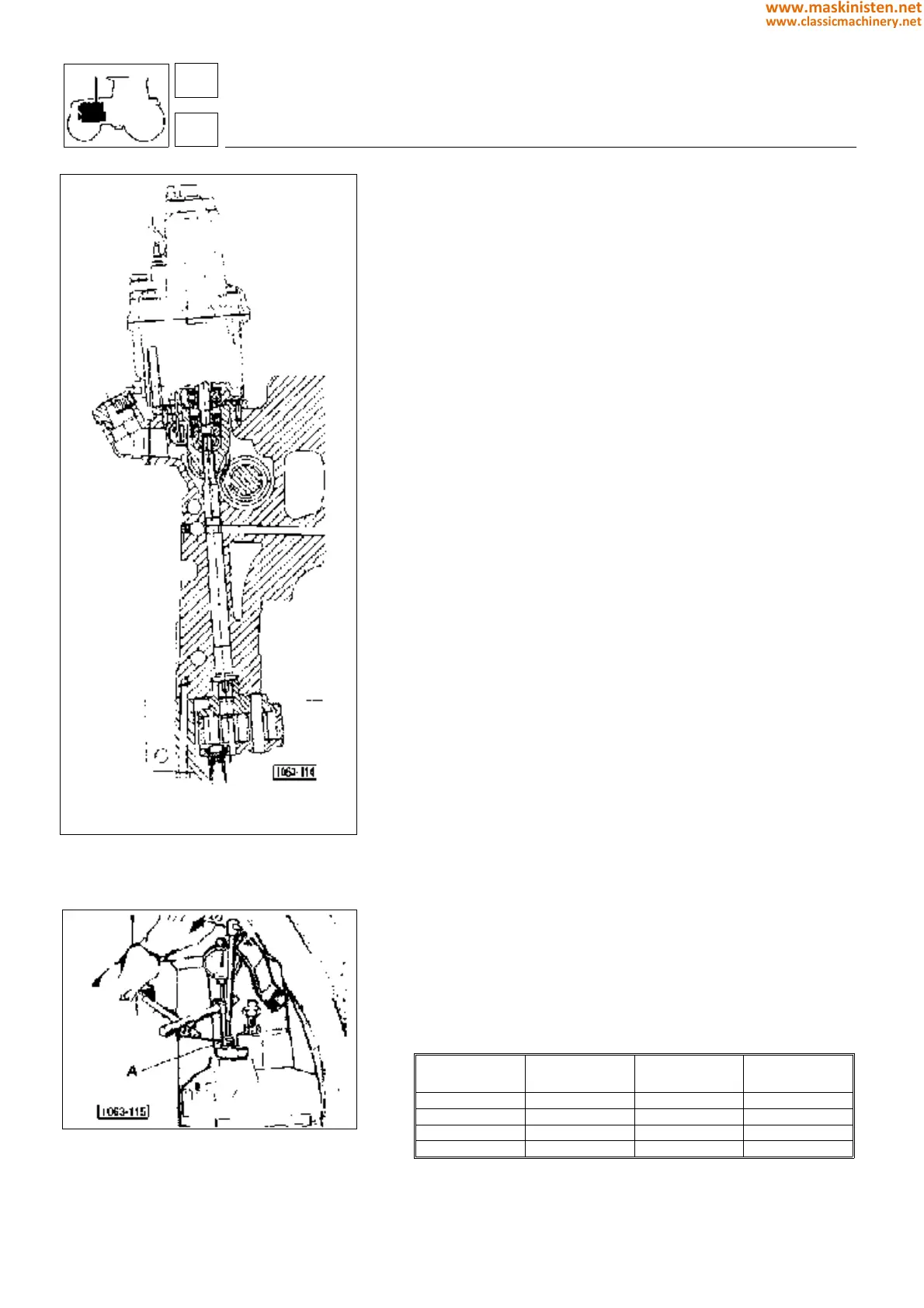

Fig. 16 - Tractor-installed engine governor unit.

Upper casing (Fig. 13)

Fit the minimum and maximum accelerator control lever travel stop

screws into the upper casing.

Mount bushing G with the relevant O-ring using nut H; install the

accelerator internal and external control levers.

Position spring-holder cap I and springs L; secure lever M and

inserted coupling N into casing.

Install travel stop rod O.

Positioning governor lever M

Operate travel stop rod O with an Allen wrench until the distance

between the lower casing edge and the travel stop rod head corner

is about 2 mm, as shown in figure 13.

Connect the upper to the lower casing, first positioning the auto-

matic extra fuel supply unit spring P on coupling N.

Calibrating engine governor

Engine governor calibration is very easy and requires no special

equipment. The procedure recommended permits all lever plays pro-

duced during engine running to be removed, since this adjustment can

be performed with engine governor assembled and engine running.

This setting is to be effected when external operations which may

involve engine governor, injection pump or injection pump control

rack replacement are performed.

Important - Whenever the governor is removed from engine, the

cable connected to the battery positive pole should be disconnec-

ted so that a sudden engine start may be prevented.

Observe the following procedure:

— start the engine and then bring to a 2000

±

100 r.p.m. by means

of the hand throttle (avoid subjecting the engine to dragging

loads and ensure it is not hunting).

— Using an Allen wrench (fig. 16) loosen the fuel maximum delivery

adjusting screw (turn it anticlockwise) until the engine is about to

stop (or keeps on running through the automatic operation of the

extra fuel supply unit stabilizing at 300 to 500 r.p.m.).

Warning: locating this condition requires most accuracy and meticulous

operating procedure and namely:

— locate approximately the point where the engine r.p.m. starts drooping;

— screw in the adjusting screw of about 3 turns to permit the

engine to be stabilized at 2000 r.p.m.;

— loosen first the adjusting screw two full turns and then continue

loosening by about 30° movements at a time and wait 2 to 3 seconds

after each screw movement until the engine stop point is located.

With the engine stopped, place the contact point of a dial gauge

on the head of screw A (fig. 16), zero the gauge, then screw in the

screw the number of turns indicated in the table, to obtain the

gauge reading indicated below:

ENGINE TYPE r.p.m. HP

No of tightening turns of

the adjusting screw

1000.4-A4 2500 80 6.3/4 (6,75 mm)

1000.4-AT2 2500 90 8.1/2 (8,5 mm)

1000.4-ATI1 2500 100 9 (9 mm)

1000.6-A1 2500 100 5.1/2 (5,5 mm)

NOTE: This adjustment can be performed at an engine oil temperture not

less than 80 °C.

Tighten the lock nut.

engine

fuel system

SILVER 80 - 90 - 100.4 - 100.6

16

1

58

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...