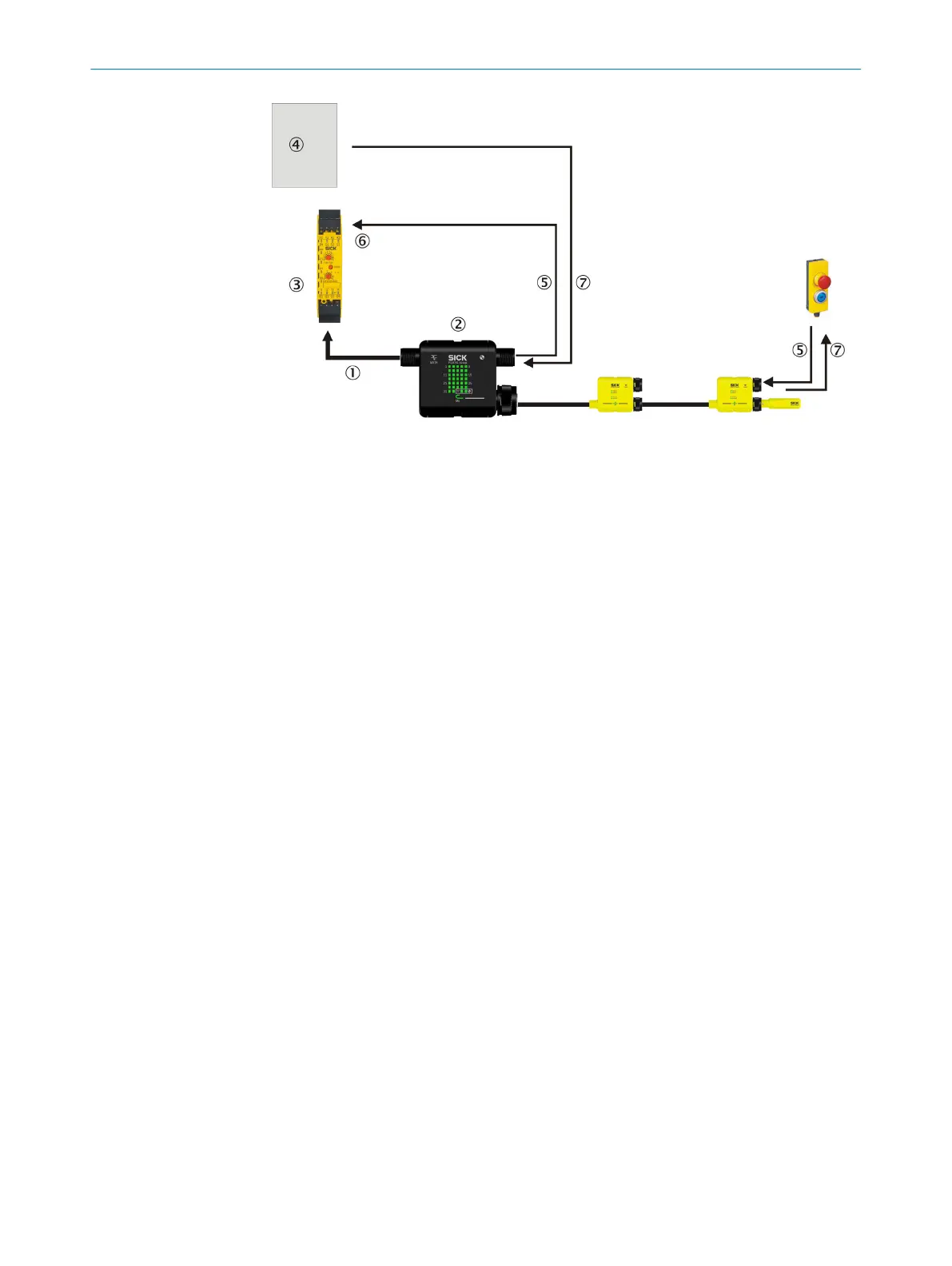

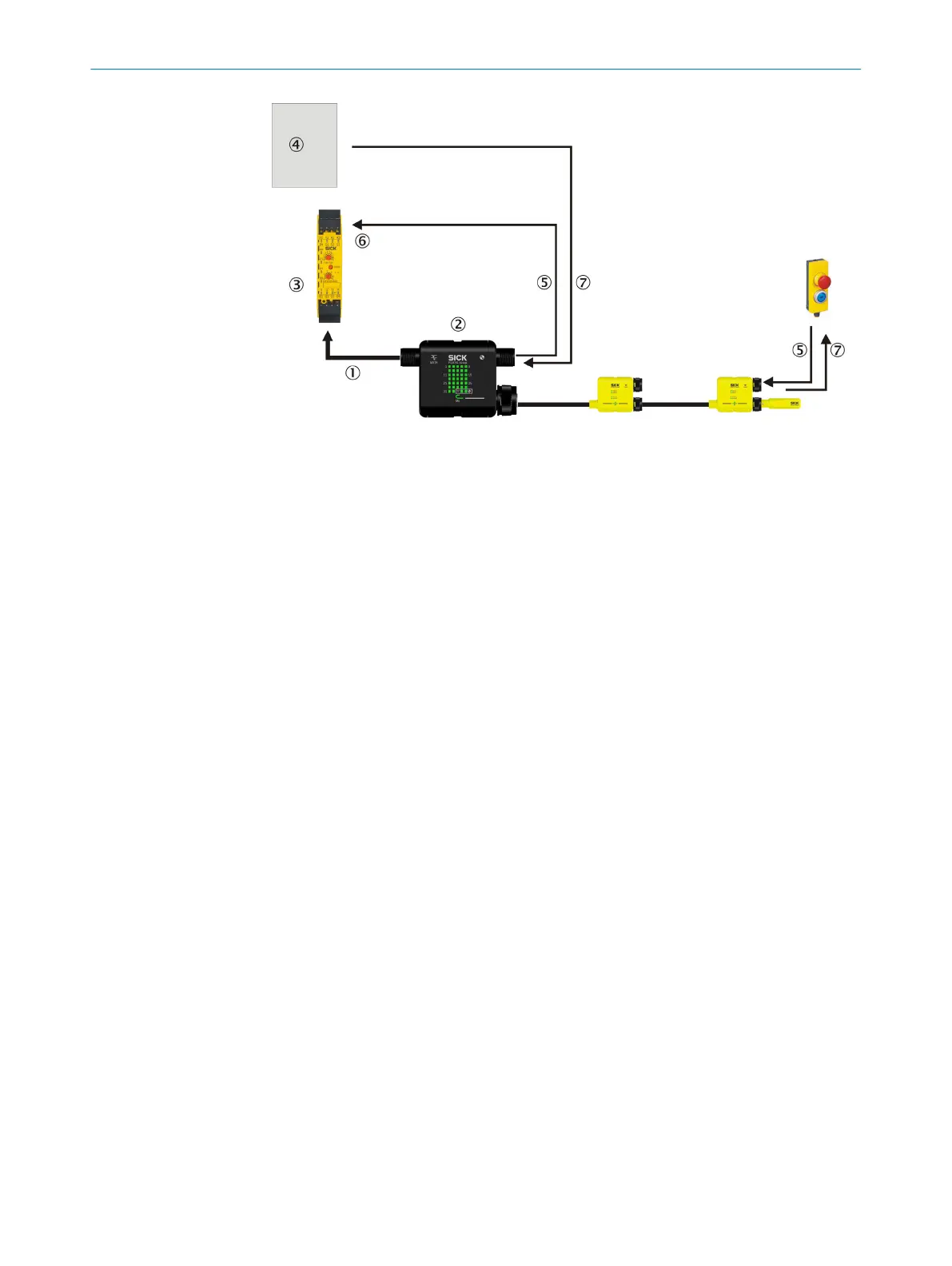

Figure 32: Reset with the Flexi Classic safety controller

1

Safe cut-off path

2

MSTR2 Flexi Loop accessory

3

Flexi Classic safety controller

4

Application (e.g. in a PLC)

5

Reset signal

6

Reset with Flexi Classic

7

Operation of the lamps

Signal propagation times via the Flexi-Loop communication always result in longer

pulse durations during signal transmission. For this reason an input signal from the

non-safe input (AUX_IN) on a Flexi Loop node has a longer pulse duration on the output

(AUX_OUT) of the MSTR2 Flexi Loop accessory.

4.4.2 Implementation of a safety locking device

Connection to EMSS node

The saf

ety switching contacts of a spring-locked safety locking device are connected to

the EMSS connections of the Flexi Loop node. Guard position monitoring for the protec‐

tive device and the interlocking device must be implemented with the same switching

element. If output monitoring of the Flexi Loop node is deactivated, the actuator signal

for the lock can be connected at the AUX_IN input. The interlocking device for the safety

locking device is connected at the AUX_OUT output.

4 DESIGN

36

O P E R A T I N G I N S T R U C T I O N S | Flexi Loop 8015836/YT10/2016-05-24 | SICK

Subject to change without notice

Loading...

Loading...