I/O configuration variants

4.2 Fail-safe operation

CPU 410-5H Process Automation/CPU 410 SMART

System Manual, 10/2013, A5E32631667-AA

51

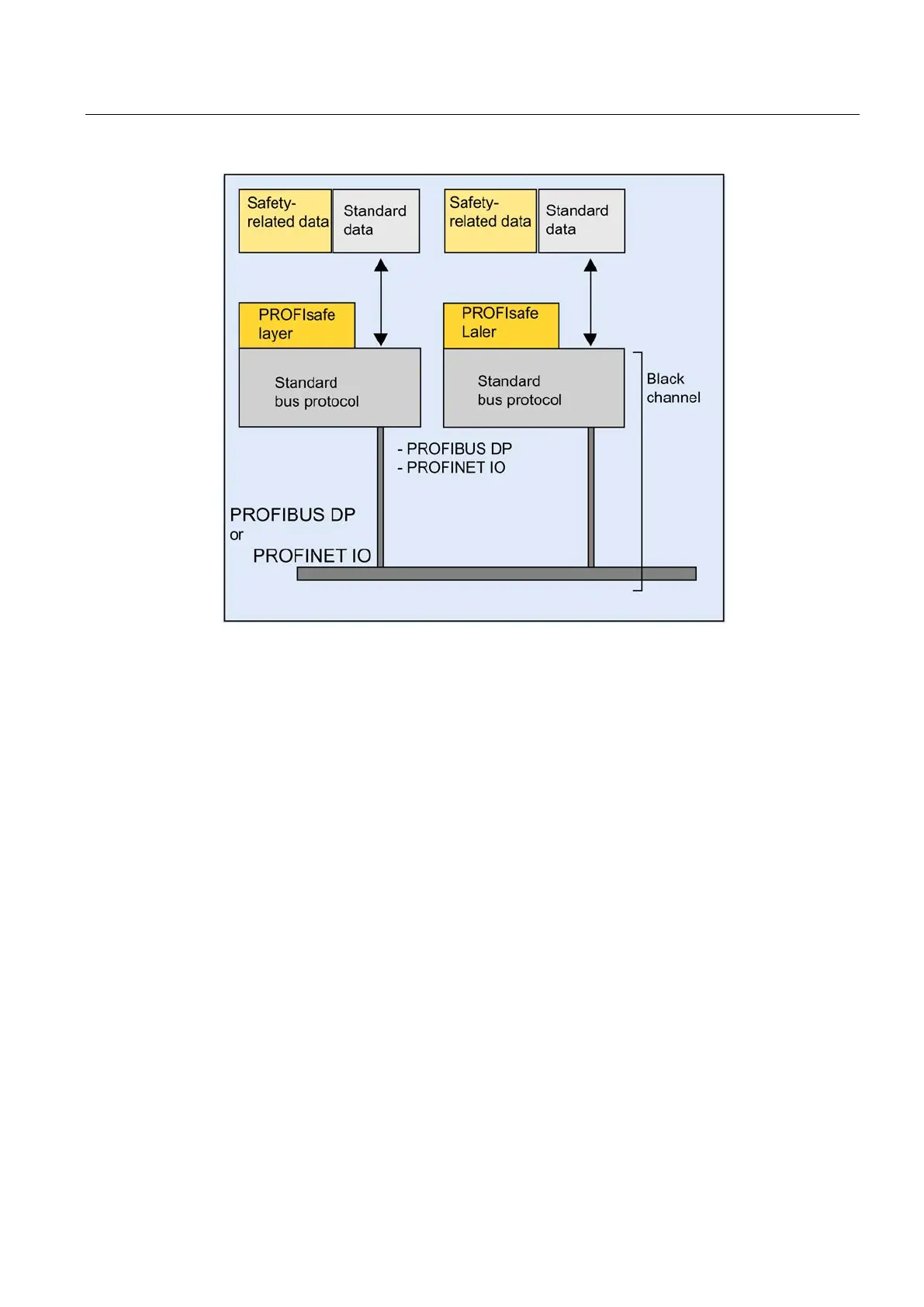

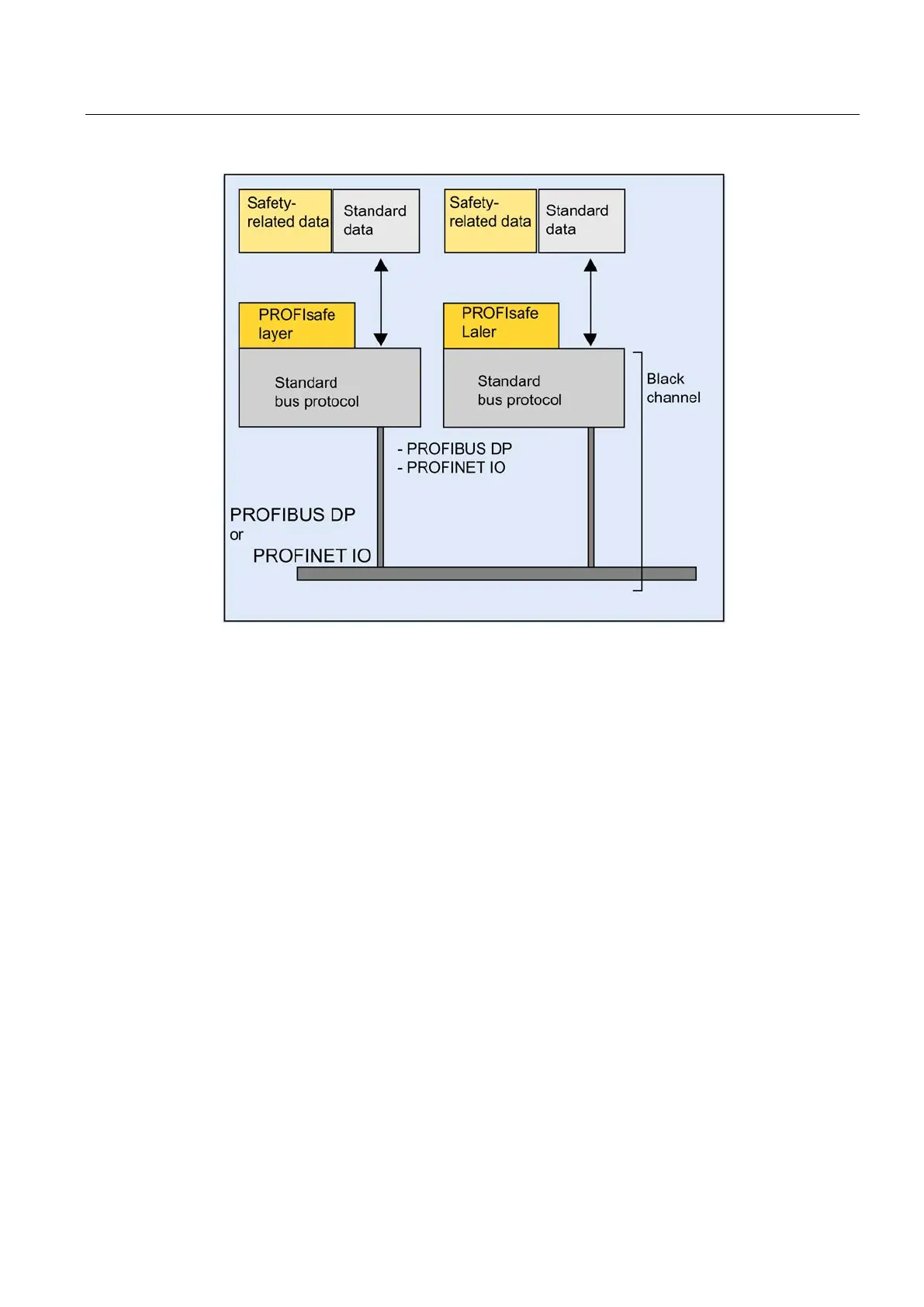

Figure 4-3 Safety-related communication

Safety-related and standard data are transmitted with PROFIsafe over the same bus line.

Black channel means that collision-free communication via a bus system with media-

independent network components (also wireless) is possible.

PROFIsafe is an open solution for safety-related communication via standard fieldbuses.

Numerous manufacturers of safety components and end users of safety technology have

helped to develop this vendor-neutral and open standard for PROFIBUS International (PI).

The PROFIsafe profile supports safe communication for the open PROFIBUS and

PROFINET standard buses. An IE/PB Link ensures integrated, safety-related communication

between PROFIBUS DP and PROFINET IO.

As a component of SIMATIC Safety Integrated, PROFIsafe is certified according to IEC

61508 (up to SIL 3), EN 954 (up to Category 4), NFPA 79-2002, NFPA 85, and thus meets

the most stringent requirements for the production and process industries.

PROFIBUS is the global standard for fieldbuses with approximately 13 million installed

nodes. Its market acceptance is so high because a large number of manufacturers offer

many products for PROFIBUS. With the PA transmission variant (IEC 1158-2), PROFIBUS

extends the unified system concept of distributed automation to the process world.

PROFINET IO is the innovative and open Industrial Ethernet standard for automation. It

enables fast reaction times and transmission of large data quantities.

PROFIsafe uses the PROFIBUS or PROFINET IO services for safe communication. A fail-

safe CPU 410 and a fail-safe slave (F-slave) exchange both user data as well as status and

control information; no additional hardware is required for this.

Loading...

Loading...