Planning the MOBY D system

4.3 Installation guidelines

MOBY D

48 System Manual, 01/2010, J31069-D0147-A6-7618

SLG D10/D10S with ANT D10

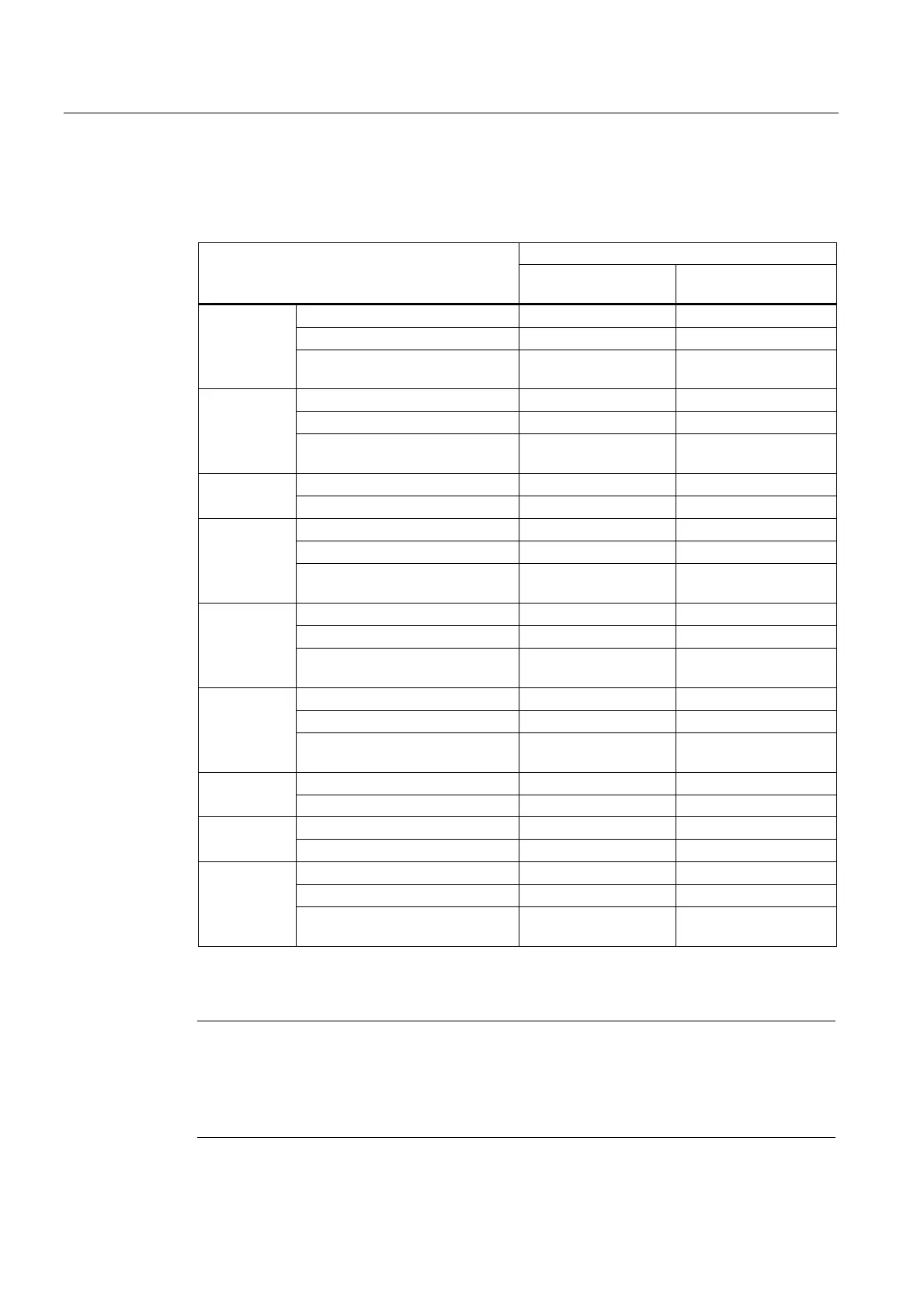

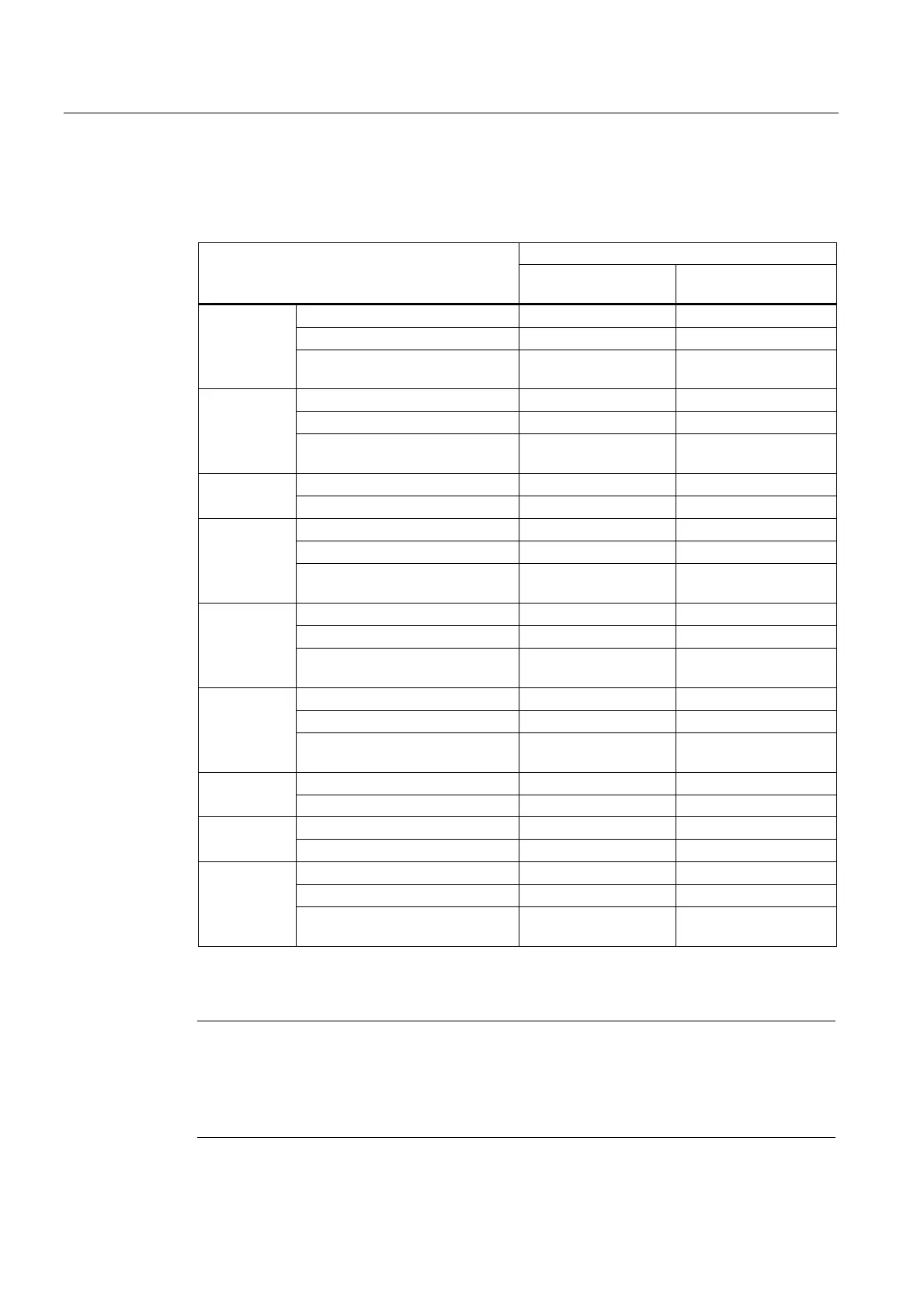

Table 4- 19 Reduction of field data by metal (in %): MDS and SLG D10/D10S with ANT D10

SLG D10/D10S with ANT D10

Transponder

On metal Flush-mounted in metal

(200 mm all-round)

Without metal 100 90

On metal; distance 20 mm 50 40

MDS D100

Flush-mounted in metal;

distance all-round 20 mm

-- --

Without metal 100 90

On metal, distance 25 mm 70 60

MDS D124

Flush-mounted in metal;

distance all-round 25 mm

-- --

Without metal 100 90 MDS D139

On metal, distance 30 mm 80 70

Without metal 100 90

On metal; distance 25 mm 65 55

MDS D160

1)

Flush-mounted in metal;

distance all-round 25 mm

-- --

Without metal 100 90

On metal; distance 25 mm 70 60

MDS D324

Flush-mounted in metal;

distance all-round 25 mm

-- --

Without metal 100 90

On metal; distance 25 mm 70 60

MDS D424

Flush-mounted in metal;

distance all-round 25 mm

-- --

Without metal 100 90 MDS D428

On metal 50 40

Without metal 100 90 MDS D460

On metal; distance 25 mm 50 40

Without metal 100 90

On metal; distance 20 mm 50 40

MDS D200

Flush-mounted in metal;

distance all-round 20 mm

-- --

1)

Values apply to metal surfaces greater than 100 mm x 100 mm

Note

The values specified in the tables must be complied with. The inductive fields may be

affected if the distance is smaller. In this case, the data transfer time would increase

unpredictably or a command would be aborted with an error.

If the distance is smaller, it is recommended that a test is performed.

Loading...

Loading...