Open loop motion control

12.2 Using motion control

S7-200 SMART

600 System Manual, V2.3, 07/2017, A5E03822230-AF

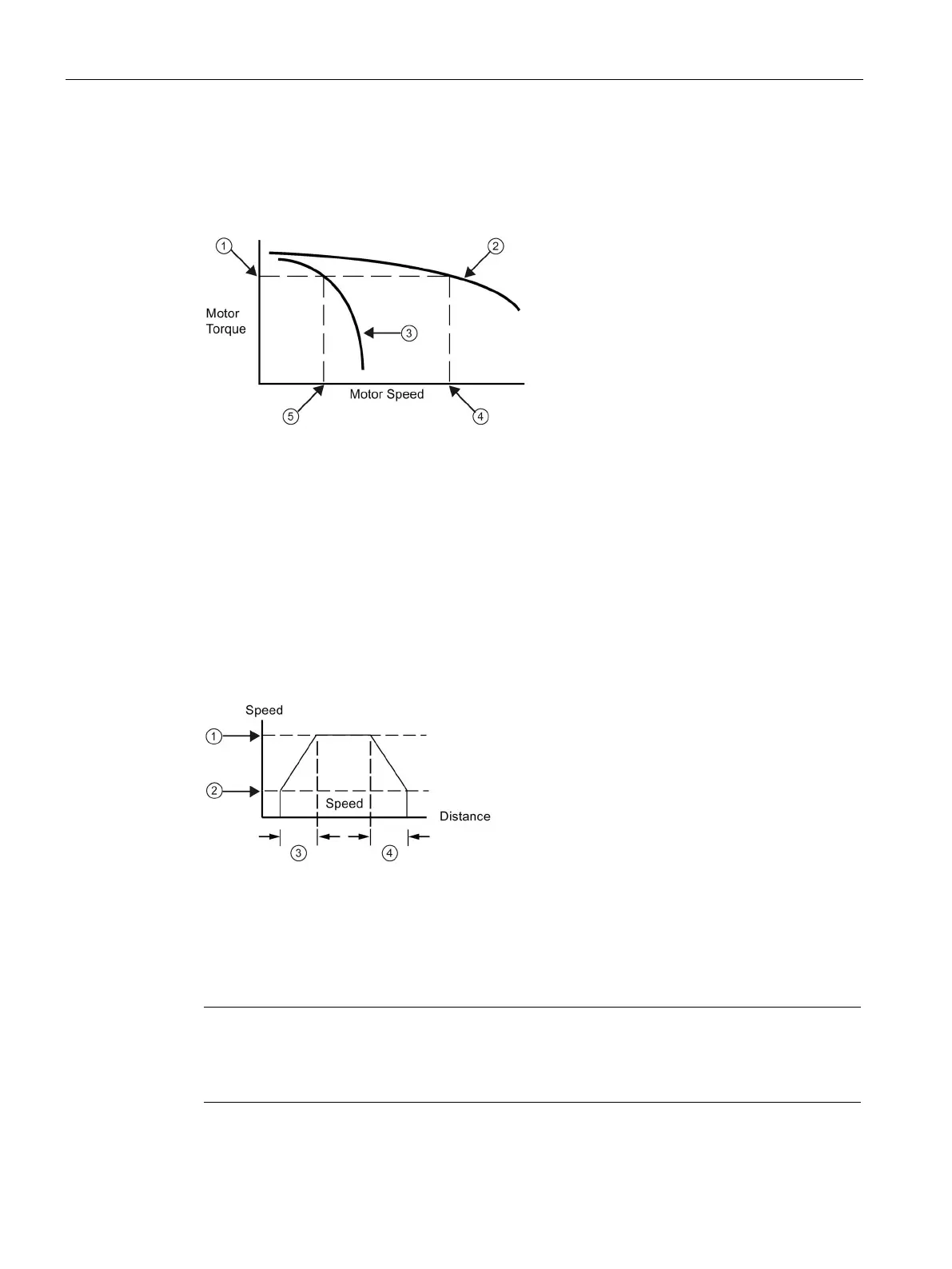

Motor data sheets have different ways of specifying the start/stop (or pull-in/pull-out) speed

for a motor and given load. Typically, a useful SS_SPEED value is 5% to 15% of the

MAX_SPEED value. To help you select the correct speeds for your application, refer to the

data sheet for your motor. The following figure shows a typical motor torque/speed curve.

Torque required to drive the load

Motor torque versus speed characteristic

Start/Stop speed versus torque: This curve moves towards lower speed as the load inertia

Maximum speed that the motor can drive the load: MAX_SPEED should not exceed this value.

Start/Stop speed (SS_SPEED) for this load

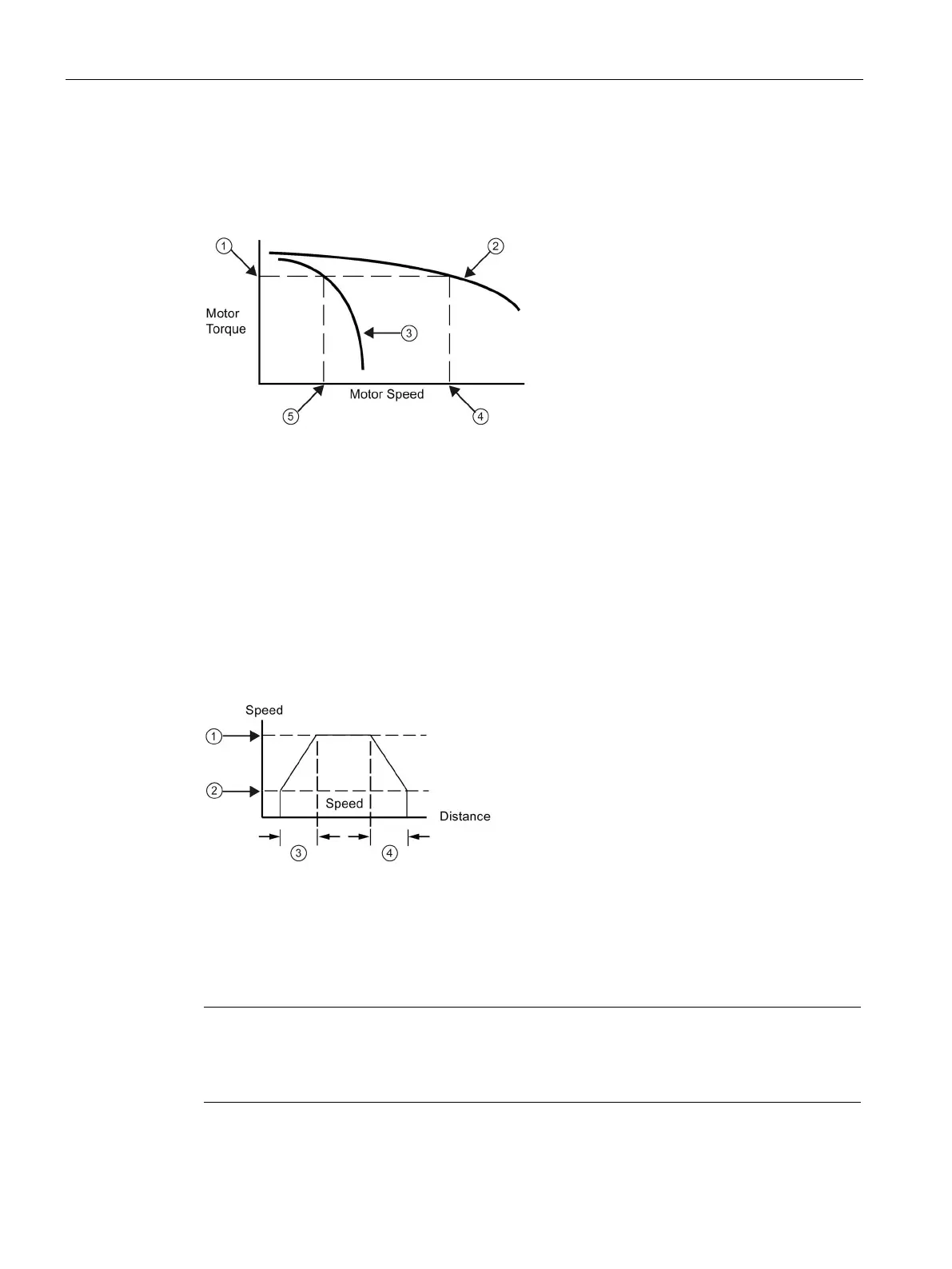

Entering the acceleration and deceleration times

As part of the configuration, you set the

acceleration and deceleration times. The

default setting for both the acceleration

time and the deceleration time is 1 se

c-

nd. Typically, motors can work with

less than 1 second. See the following

figure.

① MAX_SPEED

② SS_SPEED

③ ACCEL_TIME

④ DECEL_TIME

Note

Motor acceleration and deceleration times are determined by trial and error. You should start

by entering a large value. Optimize these settings for the application by gradually reducing

the times un

til the motor starts to stall.

Loading...

Loading...